Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 20

Using This Manual

Chapter 1

1-2

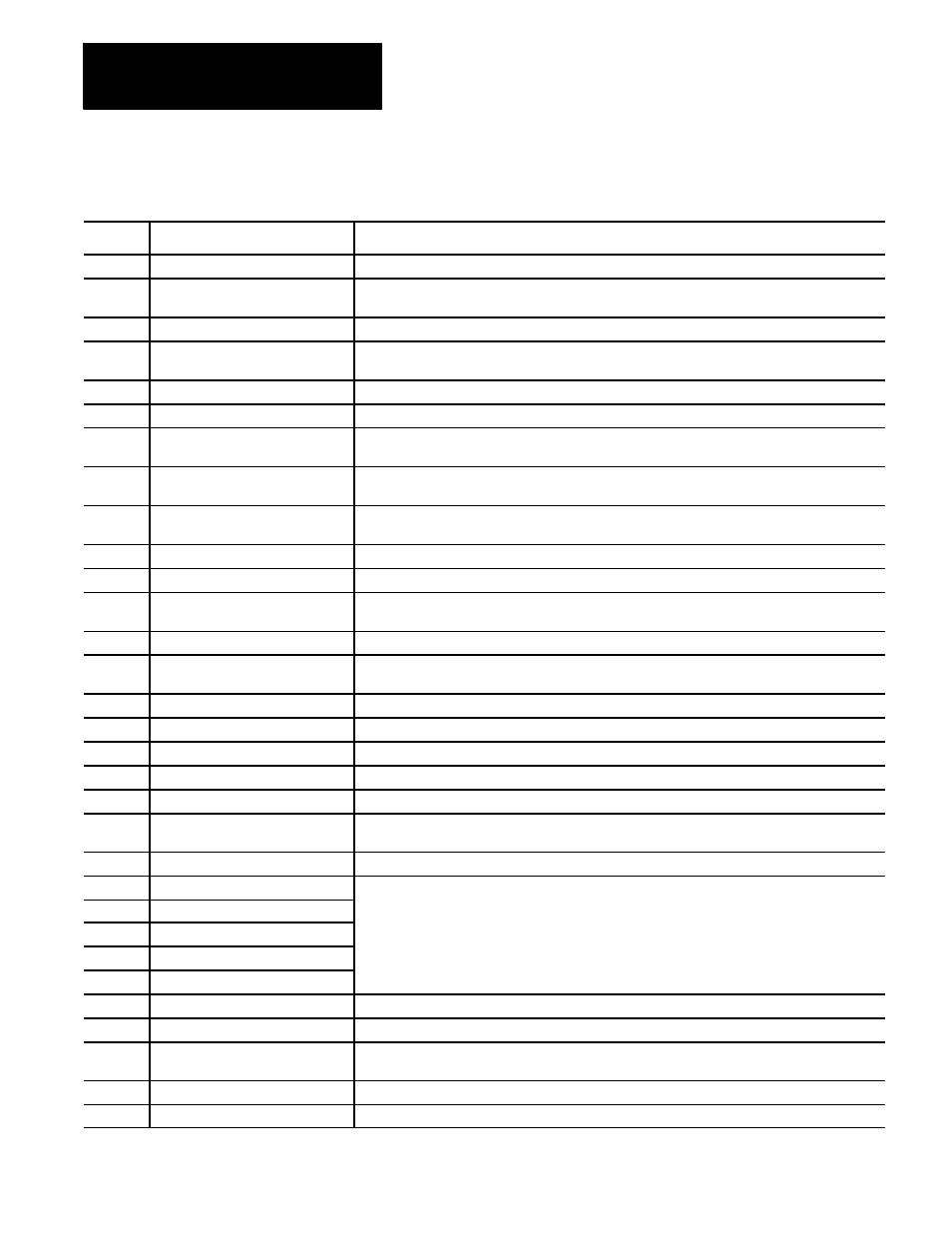

Table 1.A

Manual Organization

Chapter

Title

Summary

1

Manual Overview

Manual overview, intended audience, definition of key terms, how to proceed.

2

Basic Control Operation

A brief description of the control’s basic operation including power up, MTB panel, operator panel,

access control, and E-STOP.

3

Offset Tables and Setup

Basic setup of the offset table, other initial operating parameters.

4

Manual and MDI Operation

How to use the manual operate mode including, homing the machine, jog hand-wheel, jog

continuous, and jog increment. Also covered are the basics for MDI operation.

5

Editing Programs On Line

How to create, edit,and save a part program on line.

6

Editing Part Program Off Line

How to create, edit, and save a part programs from ODS off line.

7

Running a Program

How to select and execute a program automatically. This covers program checking as well as part

production. Also details on special running conditions.

8

Displays/ Graphics

How to access and interpret the different position displays. How to use the Quick Check and Active

Program graphics features.

9

Communications

Communications with peripheral devices. Includes sections on communication port parameters,

inputting and outputting AMP, PAL, Offsets, and programs.

10

Introduction to Programming

Tape format, structure and format of the programming language for the control.

11

Coordinate System Offsets

Machine coordinate system, Preset Work coordinate systems, PAL offsets, and external offsets

12

Overtravels and Programmable

Zones (G22, G23)

Hardware and software overtravels, programmable zone 2 (G22, G23), programmable zone 3

(G22.1, G23.1), and resetting overtravels

13

Coordinate Control

Describes absolute/incremental modes, inch/metric modes, radius/diameter modes, and scaling

14

Axis Motion

G-words define how the tool is positioned to the endpoint of a move. Also sections on automatic

machine home, dwell, mirroring, and axis clamp

15

QuickPath Plus

Describes QuickPath Plus programming

16

Using Chamfers and Corner Radius

Describes the ,C- and ,R-words programmed for chamfering and corner radius

17

Spindles

Describes spindle speed control, spindle orientation, spindle direction, and Virtual C axis

18

Programming Feedrates

Describes acc/dec, AMP-assigned feedrates, feedrate control, short block acc/dec

19

Dual Axis Operation

Describes parking, homing, programming, offset management for a dual axis

20

Tool Control

Selecting a tool. Activating and deactivating tool length offsets. Also tool control features such as

Random Tool and Tool Life Management.

21

Cutter Compensation

Describes the Tool Tip Radius Compensation feature (TTRC) that offsets for different tool diameters.

22

Using Pocket Milling Cycles

23

Using Post Milling Cycles

Describes the fixed cycles (canned cycles) for drilling operations and the G-words and parameters

used to define them.

24

Using Hemisphere Milling Cycles

Describes the fixed cycles (canned cycles) for drilling operations and the G-words and parameters

used to define them.

25

Using Irregular Pocket Milling Cycles

26

Milling Fixed Cycles

27

Skip and Gauging Cycles

Describes the 9/Series Probing features. Includes the tool measuring gauge feature.

28

Paramacros

Describes paramacros including calling, arithmetic functions, looping, decision making

29

Program Interrupts

Describes the program interrupt feature. This feature is used to call a subprogram or paramacro

program whenever a signal corresponding to that program is sent to PAL by the operator.

30

Dual Processing Systems

Necessary information on capabilities and programming methods for dual processing systems.

31

Transfer Line Cycles

Describes operation and programming of T-Line-9 part program templates for transfer line controls.