Template 19: two-axis cross feed cycle, Chapter 31 – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 853

Using Transfer Line Cycles

Chapter 31

31-51

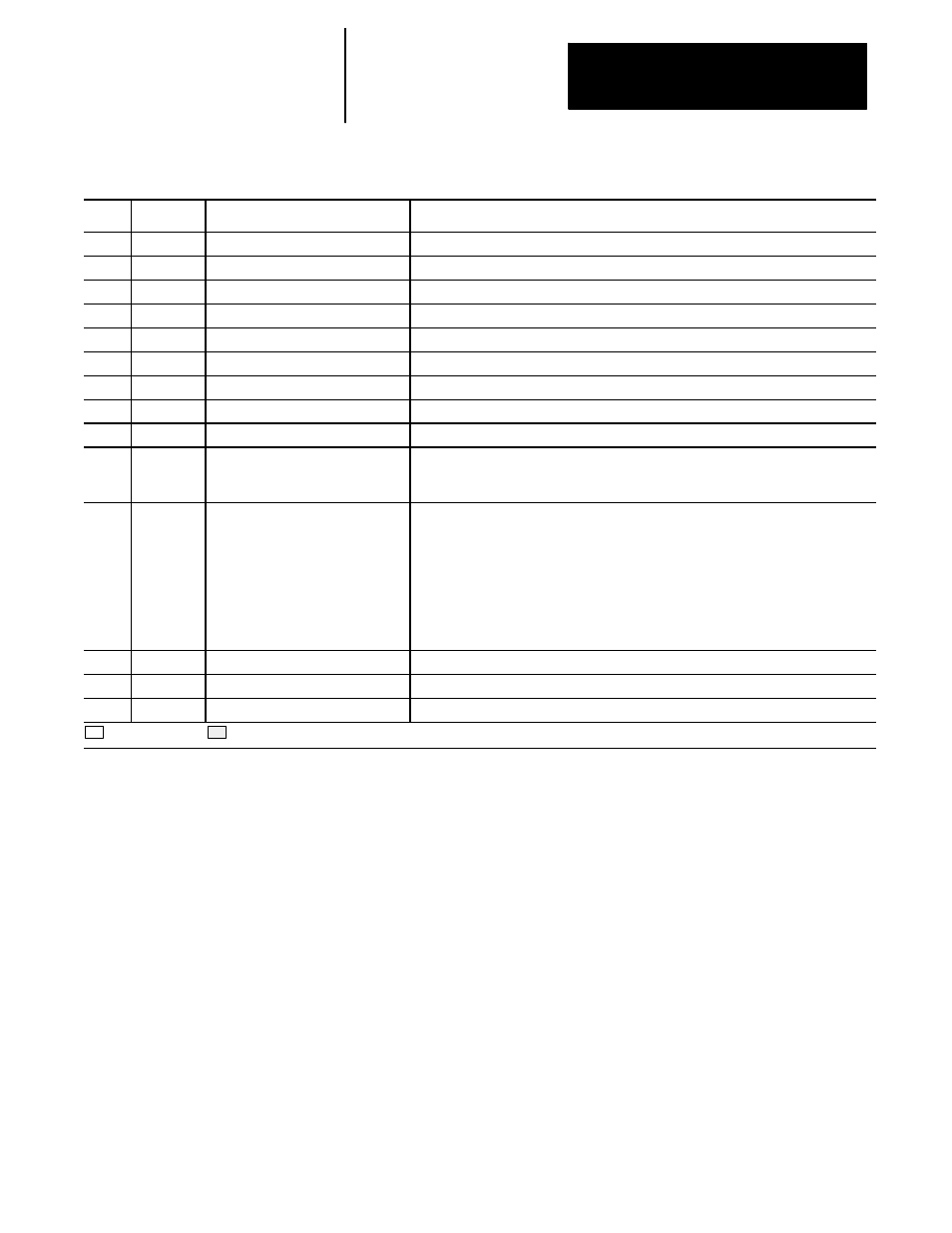

Template 19: Two-Axis Cross Feed Cycle

Letter

Paramacro

Label

Description

F

1

500

MAIN RAPID FEEDRATE

The velocity of the tool as it approaches the part.

X

1

501

MAIN FEED START

The position of the tool as it drills into the part.

F

2

502

MAIN FEEDRATE

The velocity of the tool as it drills into the part.

X

2

503

MAIN FINAL POSITION

The depth of the tool at its final position in the part.

F

3

504

CROSS FEEDRATE (MAX)

The velocity of the tool as it traverses the part.

Y

1

505

CROSS FINAL POSITION

The final position of the tool after it traverses the part.

X

3

506

MAIN RETURN POSITION

The position of the tool when it started the cycle.

Y

2

507

CROSS RETURN POSITION

The position of the slide when it started the cycle.

F

4

508

CROSS RETURN RAPID

The velocity of the slide as it returns to its starting position.

E

509

ADAPTIVE FEED MINIMUM

This is the minimum feedrate at which the control performs an adaptive feed operation.

The control will try to maintain this minimum feedrate, even if it means increasing the

adaptive feed torque percent. For more information on adaptive feed, refer to page 18-9.

Q

510

ADAPTIVE FEED TORQUE %

This is the amount of the selected servo’s continuous rated torque as entered in AMP by

your system installer. Valid ranges are from 1 to 150% of the servo’s rated torque.

Refer to your system installer’s documentation for details on the rated torque of the

servos in your system.

Important: The torque amount applied by the servo is not the cutting force. It is the

torque applied by the servo to the axis. You must calculate the equivalent cutting force

based on your machine dynamics (motor rated torque, lead screw pitch, gearing, tool

dimensions, etc...).

Y

511

CROSS TOOL CHANGE POSITION

The position the slide moves to so that a tool change may be performed.

X

512

MAIN TOOL CHANGE POSITION

The position the tool moves to so that a tool change may be performed.

I

513

HARD STOP SENSE ZONE

The position that indicates to the control that a hard stop is on the axis.

Required entry

Optional entry