Reset operations – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 774

Chapter 30

Using a 9/Series Dual--processing System

30-6

Reset Operations

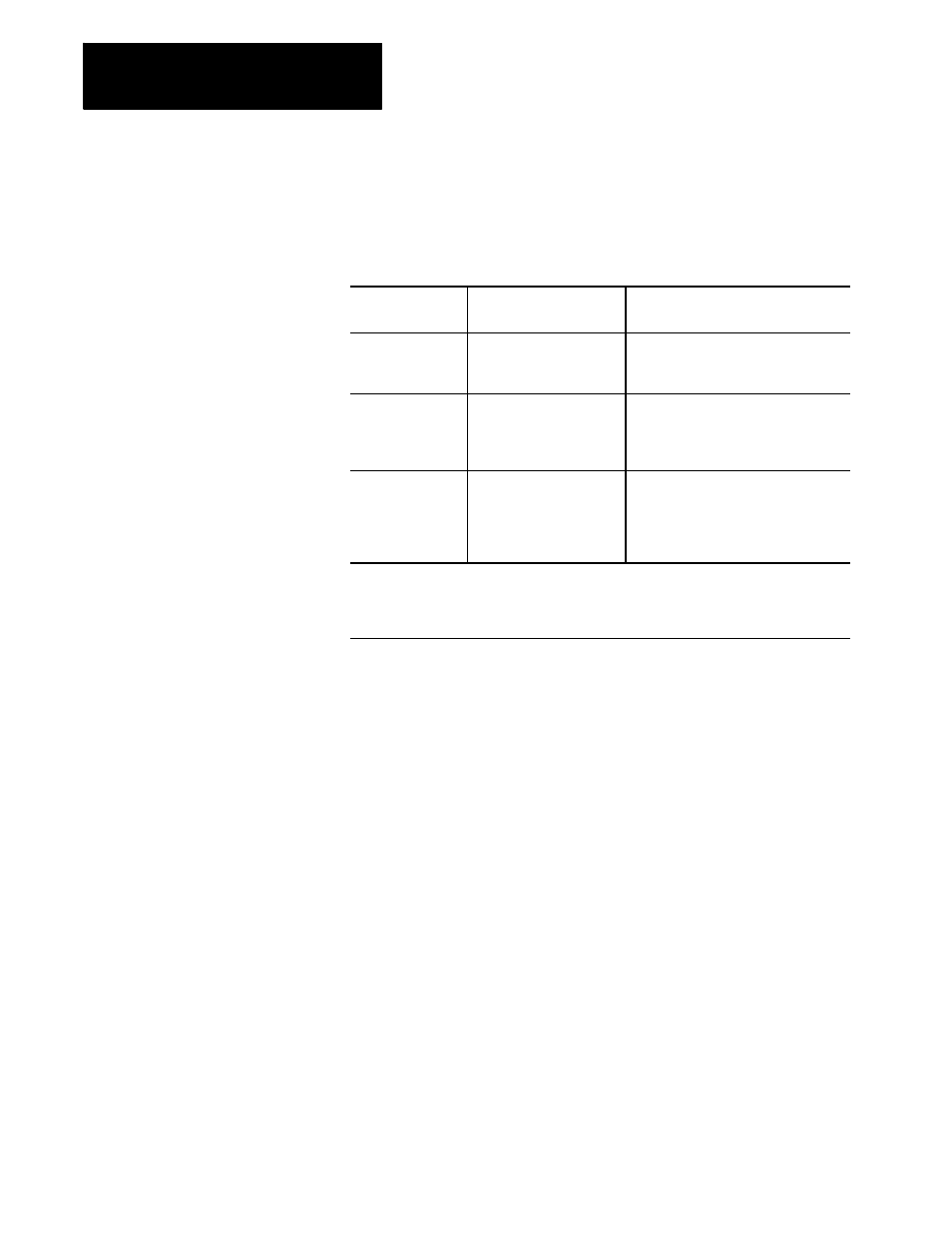

Dual-process systems have a process reset operation, in addition to the

normal block reset and control reset functions. These reset operations

work as follows:

If you want to

perform a:

Press:

The control will:

Block Reset

[RESET]

Skip the currently active block in the

currently selected process (see chapter

2).

Control Reset

[SHIFT] + [RESET]

Return the control to the default settings,

clear any program errors, and cancel

MDI commands in all processes (see

chapter 2).

Process Reset

[SHIFT] + [PROC SELECT]

Return the program of the currently

selected process to the first block. Does

not affect the additional processes (only

works on programs executed from

control memory).

If only one (or both) processes are still executing their part program when a control reset is

performed, only processes not currently executing a part program will have a control reset

performed. A message will occur in the processes executing the program stating that a control

reset is not allowed on that process.

Communication Between Processes (Shared Paramacro Parameters)

A link between the different processes of the machine is provided with the

dual-process shared paramacro parameters. These parameters are available

only on dual-process systems. They provide a link through which common

data can be passed between the different part programs executing in the

different processes of the machine. The shared dual-process parameters

are paramacro parameter numbers:

#7100 to #7199

Refer to page 28-36 for details on these paramacro parameters.