Or if your system has more than 9 axes – Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 725

Paramacros

Chapter 28

28-25

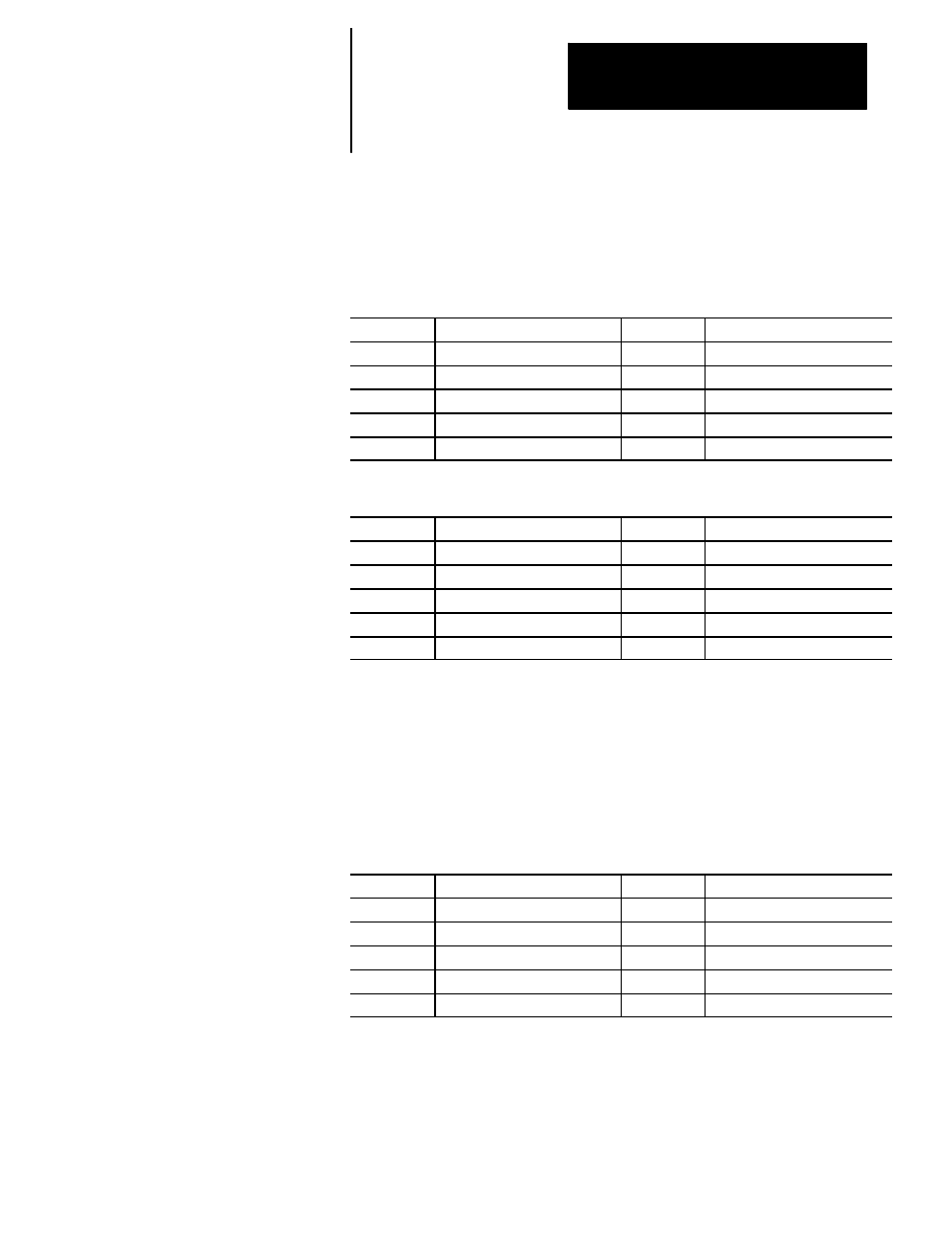

#5061 to 5069 or #5541 to 5552

Skip Signal Position Work Coordinate Position

These parameters are read-only. They correspond to the coordinates of the

cutting tool when a skip signal is received to PAL from a probe or other device

such as a switch. These are the coordinates in the work coordinate system.

5061

Axis 1 coordinate position

5067

Axis 7 coordinate position

5062

Axis 2 coordinate position

5068

Axis 8 coordinate position

5063

Axis 3 coordinate position

5069

Axis 9 coordinate position

5064

Axis 4 coordinate position

5065

Axis 5 coordinate position

5066

Axis 6 coordinate position

Or if your system has more than 9 axes:

5541

Axis 1 coordinate position

5547

Axis 7 coordinate position

5542

Axis 2 coordinate position

5548

Axis 8 coordinate position

5543

Axis 3 coordinate position

5549

Axis 9 coordinate position

5544

Axis 4 coordinate position

5550

Axis 10 coordinate position

5545

Axis 5 coordinate position

5551

Axis 11 coordinate position

5546

Axis 6 coordinate position

5552

Axis 12 coordinate position

The system installer determines in AMP the name (or word) that is used to

define the axis.

#5071 to 5079 or #5561 to 5562

Skip Signal Position Machine Coordinate System

These parameters are read-only. They correspond to the coordinates of the

cutting tool when a skip signal is received to PAL from a probe or other

device such as a switch. These are the coordinates in the machine

(absolute) coordinate system.

5071

Axis 1 coordinate position

5077

Axis 7 coordinate position

5072

Axis 2 coordinate position

5078

Axis 8 coordinate position

5073

Axis 3 coordinate position

5079

Axis 9 coordinate position

5074

Axis 4 coordinate position

5075

Axis 5 coordinate position

5076

Axis 6 coordinate position