Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 350

Chapter 12

Overtravels and Programmable Zones

12-12

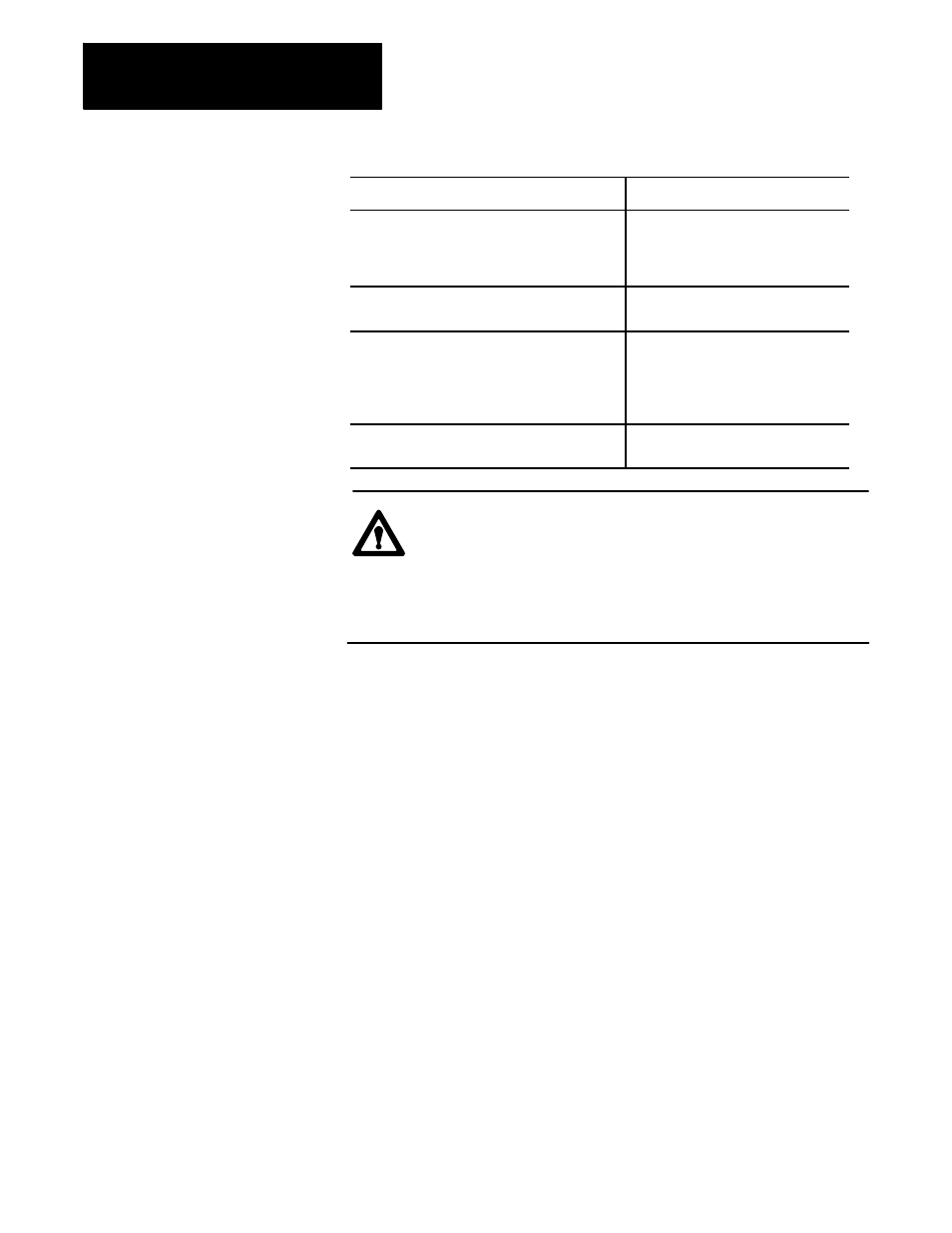

These blocks:

Results in:

G22 X10 I--10 Y14 J--14 Z1 K--1;

G22 U5 I--5 V13 J--2 W11 K10;

G22 A3 I2 B7 J--7 C12 K11;

upper and lower zone 3 limits for all 9

axes are changed. Zones 2 and 3 are

both activated when the first block in this

series of blocks is executed.

G22 X1 Y2 Z3 U4 V5 W6 A7 B8 C9;

upper zone 3 limits are changed for all 9

axes. Zones 2 and 3 are both activated.

G22 X1 Y2 Z3 U4 V5 W6 A7 B8 C9 I--1 J--2 K--3;

upper and lower zone 3 limits for all 9

axes are changed. (I sets lower for X, U,

and A: J sets lower for Y, V, and B: K

sets lower limits for Z, W, and C). Zones

2 and 3 are both activate.

G22 K--10;

error is generated. Current status of

zones remains in current state (on or off).

WARNING: When using multiple blocks to set the zone 3

limits, keep in mind zone 3 is activated after the first G22 block.

This will result in zone 3 being activated before you have

completed changes to the zone 3 values. This can cause the

control to miss-interpret zone 3 as an internal or external zone,

depending on the tool location at the time of the zone activation.

The zone values entered in a G22 block always reference coordinate values

in the machine coordinate system.

If a value for a maximum axis parameter is less than the value set for an

axis current minimum parameter, or if a value for a minimum axis

parameter is set greater than the value set for an axis current maximum

value, the control displays the message:

“INVALID VALUE (MAX < MIN) FOR ZONE 3 AXIS (X)”

This message displays the name of the axis that has been set incorrectly. It

does not indicate if it is the minimum or maximum value that is incorrect.