Rockwell Automation 8520-MUM 9/Series CNC Mill Operation and Programming Manual Documentation Set User Manual

Page 38

Basic Control Operation

Chapter 2

2-14

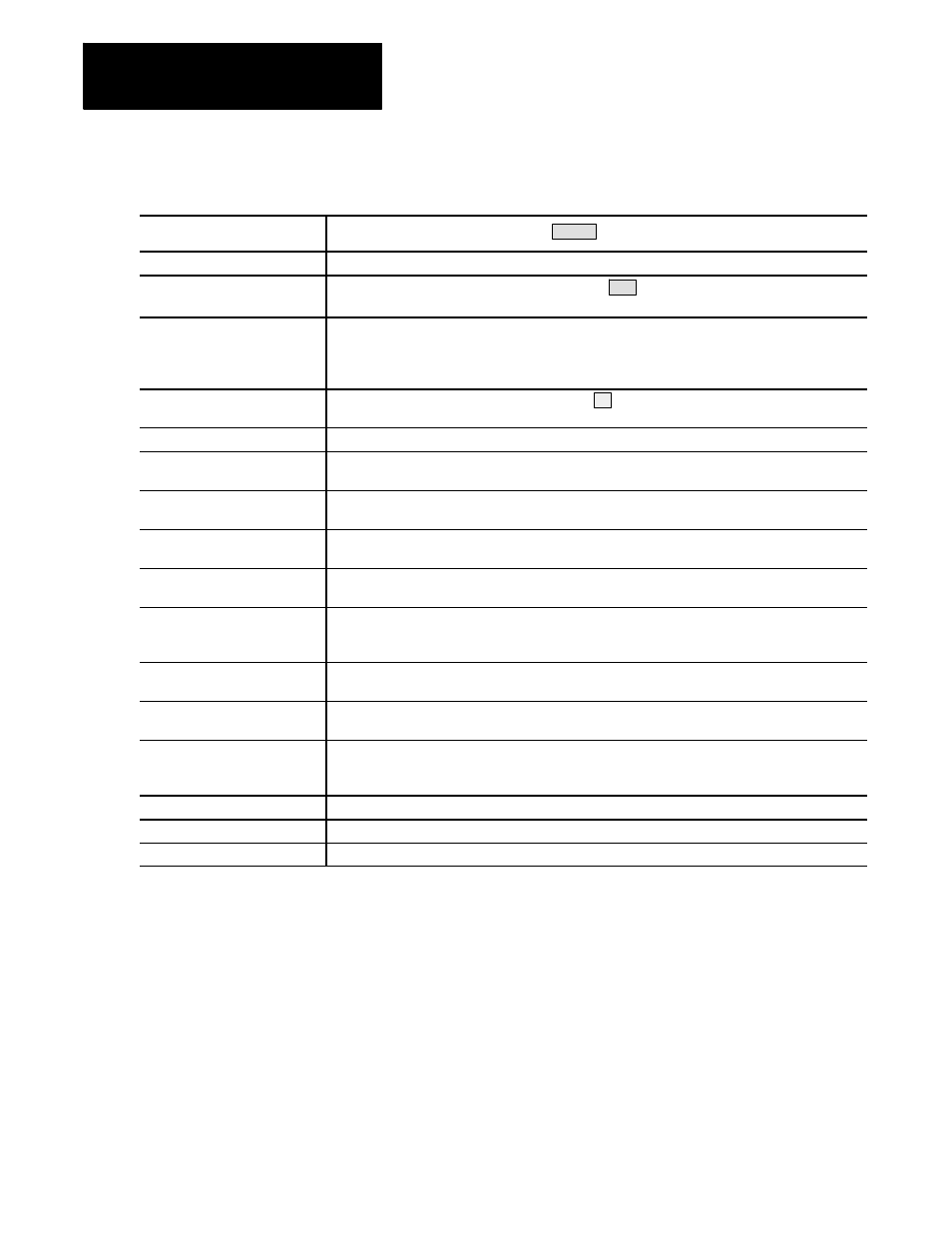

Table 2.D

Functions of the Buttons on the Push-Button MTB Panel

Switch or Button Name

= Default for Push-Button MTB Panel

How It Works

SPINDLE SPEED OVERRIDE

Selects the override for programmed spindle speeds in 5% increments within a range of 50% to 120%.

SPINDLE or

SPINDLE DIRECTION

Selects spindle rotation, clockwise (CW), spindle stop (OFF), counterclockwise (CCW). Can be

overridden by any programmed spindle direction command.

FEEDRATE OVERRIDE

Selects a feedrate override percentage for the feedrate programmed with an F--word in any of the

feedrates modes (G93/G94/G95) and the reciprocation feedrate programmed with an E--word.

programmed feedrate in 10% increments. When set to 0%, the control is effectively in feedhold.

RAPID FEEDRATE OVERRIDE

Selects the override for rapid feedrates. Select from F1, 25%, 50%, and 100% where F1 is a rapid

feedrate override setting established in AMP by the system installer.

EMERGENCY STOP

This button stops machine operation and disables the spindle and axis drives when pressed.

E-STOP RESET

This button resets an emergency stop condition when pressed. Before pressing this button the

condition that caused the E-Stop should be resolved.

CYCLE START

The control begins or resumes part program execution, MDI program execution, or program check

when this button is pressed.

CYCLE STOP

The control stops part program execution, MDI execution, or program check when this button is

pressed. If pressed during the execution of a program block a cycle suspend state occurs.

SINGLE BLOCK

The control executes or checks one block of a part program or MDI entry each time the

AXIS/DIRECTION

These buttons are used for manual operations. They select an axis and direction when

handwheel, these buttons select an axis only. Direction is then determined by handwheel rotation.

TRVRS

Hold this button down while executing a continuous jog move to override the active feedrate and jog an

axis in rapid traverse.

F1 - F4

The functions for these buttons are assigned by the system installer. Refer to the documentation

prepared by the system installer for details.

JOG RETRACT

Use jog retract to jog a cutting tool away from the workpiece during automatic or MDI program

execution. The control can retrace the jog moves and return the cutting tool automatically to the

workpiece by pressing

BLOCK RETRACE

To retrace the tool path in a part program already executed (up to 15 blocks), press this button.

ON

Turns on power to the control.

OFF

Turns off power to the control.

Important: Many of the override switch settings may be disabled by

programming the correct M-code or setting a particular paramacro

parameter. Refer to their respective sections for details on these features.