Fig. 3-69, Fig. 3 -69, 4) – SkyTrak 6042 Service Manual User Manual

Page 77

3.31

Model 6042 Legacy

Origin 7/02

Boom

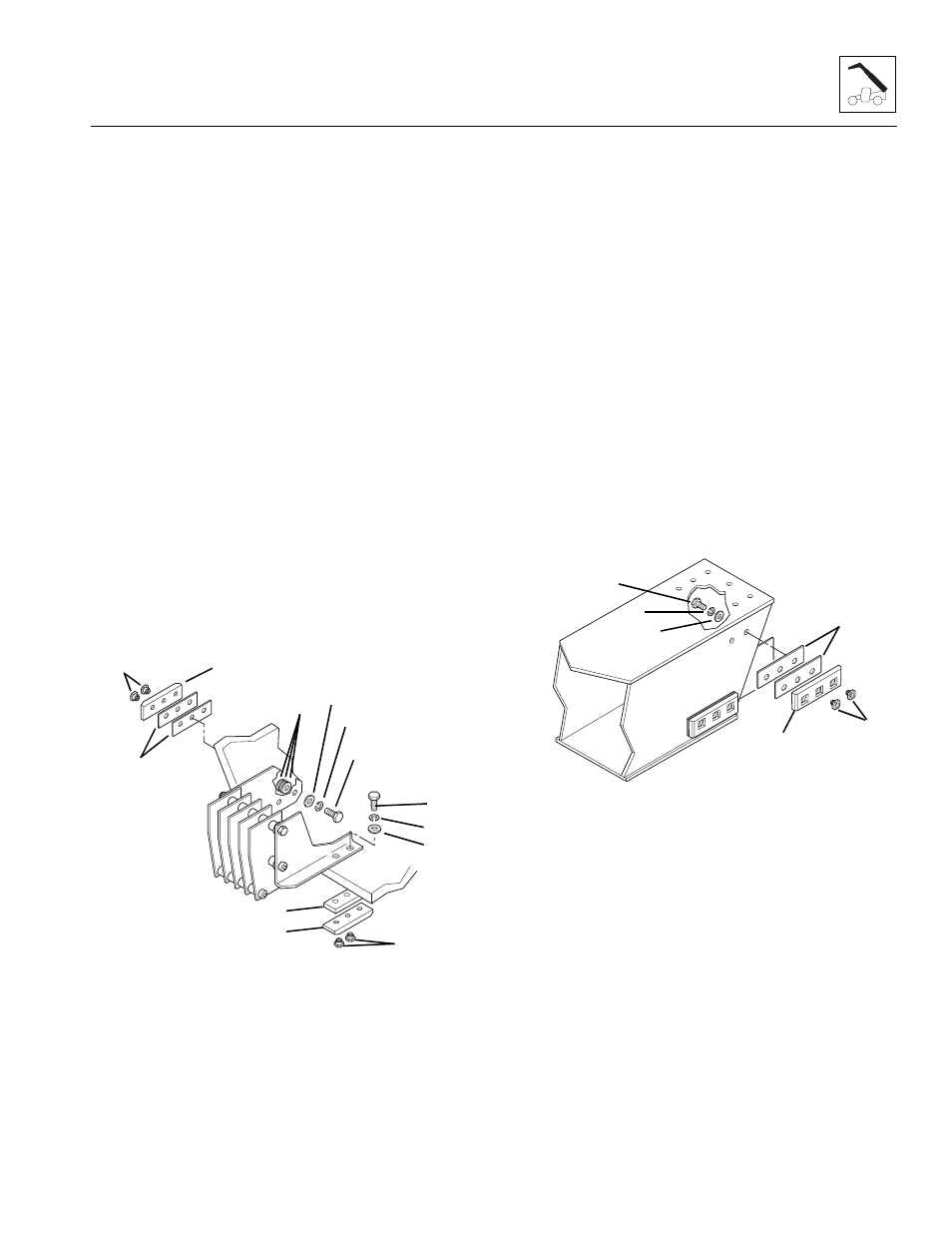

c. Place the wear pad inserts (Fig. 3-69, 5), saved,

into the cavities in the wear pad (6). Be sure the

inserts are seated completely in the cavities.

d. Install the wear pad (Fig. 3-69, 6) onto the

capscrews. Be careful not to push the wear pad

inserts out of the wear pads.

e. Apply Loctite® 242 threadlocker to the threads of

the two 3/8-16 x 1-1/2" capscrews (Fig. 3-69, 7),

saved. Insert a capscrew with a 3/8"

lockwasher (8), saved, and a 3/8" flat washer (9),

saved, through each of the mounting holes in the

right side plate of the hose reel assembly.

f. Place the wear pad inserts (Fig. 3 -69, 10),

saved, into the cavities in the wear pad (11),

saved. Be sure the inserts are seated completely

into the cavities.

g. Place the wear pad spacer (Fig. 3-69, 12),

saved, and the wear pad under the intermediate

boom. With the holes offset as noted in disas-

sembly, align the holes in the wear pad, and

secure the hose reel, wear pad spacer and wear

pad to the intermediate boom. Be careful not to

push the wear pad inserts out of the wear pads.

h. Torque all wear pad mounting capscrews to

31 ±3 lb-ft (42 ±4 Nm).

i. Fill all wear pad cavities with a good grade of

lithium-based EP grease.

Figure 3-69 Hose Reel and Wear Pads

4. Install the intermediate boom side wear pads:

a. Apply Loctite

®

242 threadlocker to the threads of

the 3/8-16 x 3/4" capscrews (Fig. 3-70, 1),

saved. Insert a capscrew with a 3/8"

lockwasher (2), saved, and a 3/8" flat washer (3),

saved, through each of the wear pad mounting

holes in the side plates of the intermediate boom.

b. Place the wear pad shims (Fig. 3-70, 4), saved if

present, onto the capscrews. Place the shims

onto the capscrews with the holes offset as noted

in disassembly.

c. Place the wear pad inserts (Fig. 3-70, 5), saved,

into the cavities in the wear pad (6). Be sure the

inserts are seated completely in the cavities.

d. Install the wear pad (Fig. 3-70, 6) onto the

capscrews. Be careful not to push the wear pad

inserts out of the wear pads.

e. Torque all wear pad mounting capscrews to

31 ±3 lb-ft (42 ±4 Nm).

f. Fill all wear pad cavities with a good grade of

lithium-based EP grease.

Figure 3- 70 Side Wear Pads

MH1500

3

2

1

5

4

6

3

10

11

12

7

8

9

MH1510

1

2

3

4

5

6