Warning – SkyTrak 6042 Service Manual User Manual

Page 301

8.69

Model 6042 Legacy

Origin 7/02

Hydraulic System

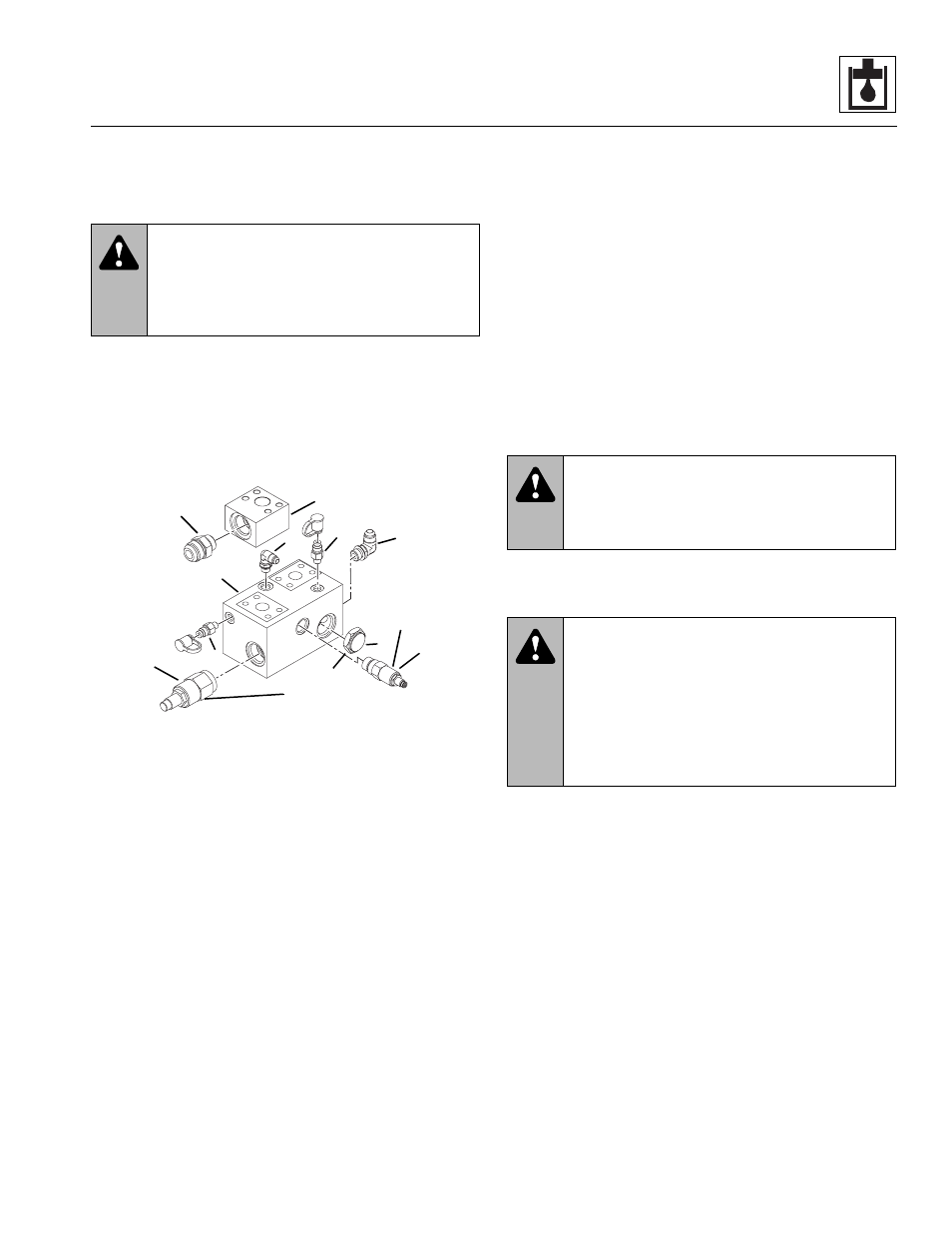

b. Unloader Valve Disassembly, Inspection and

Assembly

1. Safely secure the unloader valve (Fig. 8-36, 1) in a

bench vise or by other suitable means.

2. Slowly remove the check valve (Fig. 8 -36, 2).

3. Remove the relief valve (Fig. 8-36, 3) and remove

the differential pressure sense valve (4).

4. Remove the diagnostic test nipples (Fig. 8 -36, 5)

and remaining fittings (6). Remove the fitting (8) from

the manifold (7).

Figure 8-36 Unloader Valve Components

5. Clean metal parts with an approved solvent such as

triclorethylene and blow dry.

6. Inspect all sealing surfaces. They must be clean,

smooth and free of damage, and have no indication

of wear. Replace parts if damaged or worn.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and operation.

Lubricate seals and o-rings with clean hydraulic oil.

7. Install the check valve (Fig. 8-36, 2) and torque to

80-90 lb-ft (108-122 Nm).

8. Install the relief valve assembly (Fig. 8-36, 3) and

torque to 35-40 lb-ft (47-54 Nm).

9. Install the differential pressure sense valve assembly

(Fig. 8-36, 4) and torque to 80-90 lb-ft (108-122 Nm).

10. Install diagnostic nipples (Fig. 8-36, 5) and fittings (6).

Install the fitting (8) on the manifold (7).

c. Unloader Valve Installation

1. Secure the unloader valve (Fig. 8-35, 1) to the

vehicle frame with the three hex-head capscrews (7),

the three lockwashers (8) and the three washers (9).

Torque the capscrews to 31 lb-ft (42 Nm). Secure the

check valve manifold (10) to the unloader valve with

the flange connection.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and operation.

Lubricate seals and o-rings with clean hydraulic oil.

2. Connect the hydraulic lines to their appropriate ports

on the unloader valve or check valve manifold.

3. Check the routing of all hoses, wiring and tubing for

sharp bends or interference with any rotating

members. All tube and hose clamps must be tight.

4. Start the engine and run at approximately one-third

to one-half throttle for approximately one minute without

moving the vehicle or operating any hydraulic functions.

5. Inspect for leaks and check all fluid levels. The

hydraulic reservoir oil level must be to the middle of

the sight gauge.

Note: Check for leaks and tighten fittings or repair as

required before continuing. Wipe up any hydraulic fluid

spillage in, on, near and around the vehicle, work area and

tools.

d. Unloader Valve Pressure Check Test

1. Monitor the valve pressure at the VG test port

(Fig. 8 -36, 7) on the unloader valve. It should be at

250-300 psi (17-21 bar) within moments after

starting the engine. Adjust the differential pressure

sense valve as required.

2. Check the pressure at the VG test port (Fig. 8-36, 7)

on the unloader valve while performing the boom lower

function. It should be 3,000 psi (207 bar). Adjust the

relief valve as required.

WARNING:

Significant pressure may be

trapped inside the valve. Exercise caution

when removing a valve. Escaping hydraulic

fluid under pressure can penetrate the skin,

causing death or serious injury.

LSG

P

T

VG

LS

MA7150

1

2

3

4

Torque to

80-90 lb-ft

(108-122 Nm)

Torque to

35-40 lb-ft

(47-54 Nm)

6

5

5

7

8

6

WARNING:

Avoid prolonged engine

operation in closed areas with inadequate

ventilation. Failure to properly ventilate exhaust

fumes can result in death or serious injury.

WARNING:

Hydraulic oil leaking under

pressure can penetrate the skin and cause

severe personal injury. DO NOT use your hand

or any part of your body to check for hydraulic

leaks. When checking for hydraulic leaks, wear

safety glasses and gloves to help provide

protection from spraying hydraulic oil. Use a

piece of cardboard or paper to search for leaks.