SkyTrak 6042 Service Manual User Manual

Page 160

Axles, Drive Shafts, Wheels and Tires

5.8

Model 6042 Legacy

Origin 7/02

b. Axle Inspection, Internal Service and Repair

Note: Detailed axle service instructions (covering axle,

brakes and wheel-end safety, repair, disassembly,

reassembly, adjustment and troubleshooting information)

are provided in the ZF Axle Repair Manual, Model MS-T

3045, OmniQuip P/N 8990419 (ZF P/N 5871 550 002).

The axle should be checked, serviced and repaired only

by experienced service technicians who are aware of all

safety instructions and particular component features.

c. Installation

The front and rear axle assemblies differ in that the front

axle assembly is equipped with a parking brake

mechanism and limited-slip feature; the rear axle has

neither. The steps below outline a typical axle installation

procedure, suitable for either the front or the rear axle

assembly.

1. Before proceeding, ensure that the vehicle will

remain in place during axle installation. Block the

front and rear of both tires on the axle that is already

installed on the vehicle.

2. If applicable, raise the vehicle using a suitable jack

or hoist. Place suitable supports beneath the frame

and lower the vehicle onto the supports, allowing

enough room for axle installation. Ensure that the

vehicle will remain in place during axle installation.

3. Using a suitable jack, hoist or overhead crane and

sling, remove the axle (Fig. 5 -6, 1-Front or 2-Rear)

from its support or holding stand. Balance the axle,

and prevent it from tipping, turning or falling while

positioning it beneath the vehicle. DO NOT raise or

otherwise disturb the vehicle while installing the axle.

Keep the axle supported and balanced on the jack,

hoist or overhead crane and sling throughout the

installation procedure.

4. Install the four hex-head capscrews (Fig. 5-6, 3),

four hex nuts (4), and eight hardened washers (5)

securing the front or rear axle supports to the vehicle

frame. Torque to 600-680 lb-ft (813-922 Nm).

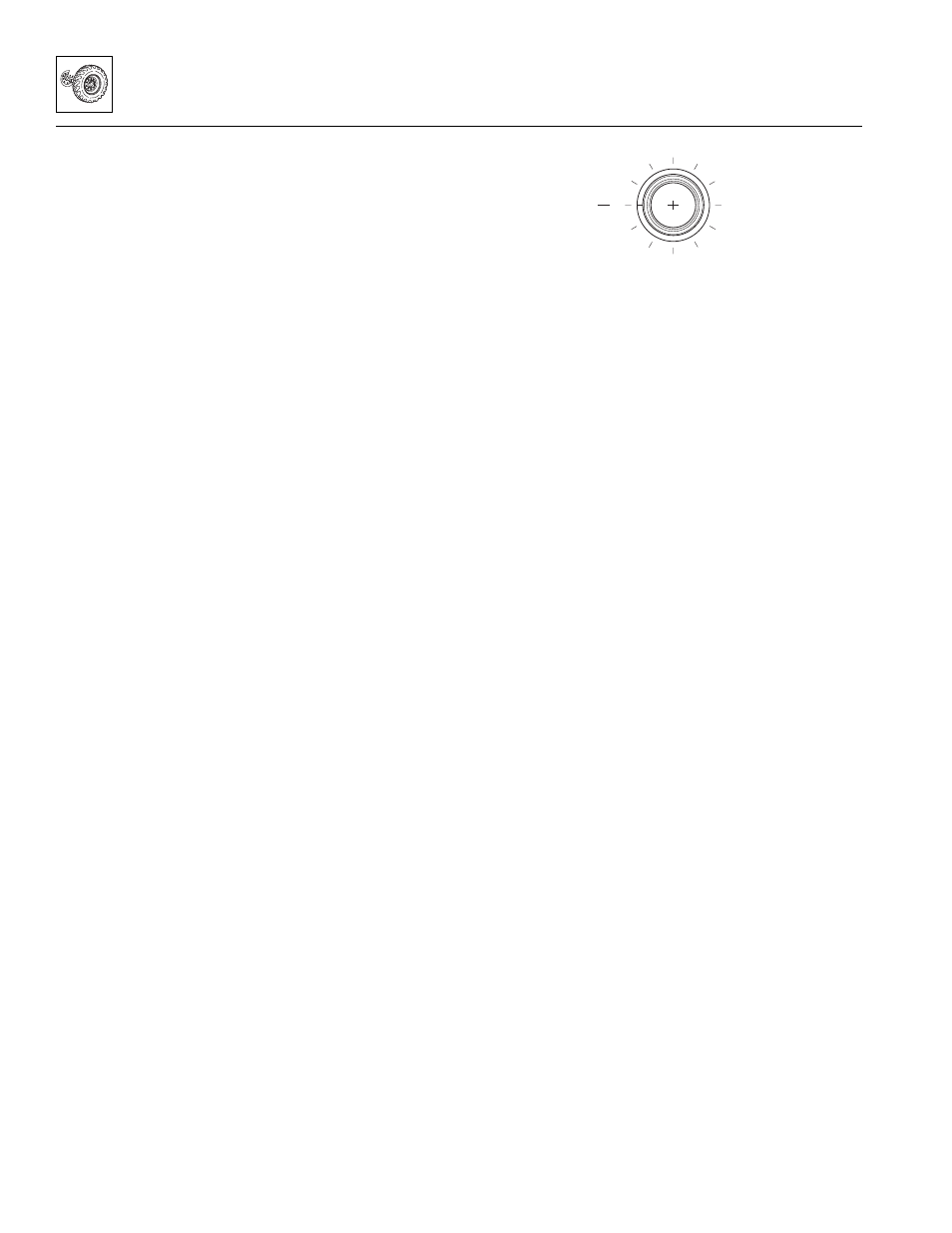

Note: If a new frame sway (front) or stabilizer (rear)

cylinder bearings (Fig. 5-6, 6) have been installed in the

axles or vehicle frame, the fracture (Fig. 5-5, 1) in the

bearing race must be positioned at the 9 o’clock position

as shown in Fig. 5-5.

Figure 5- 5 Frame Sway Cylinder Bearing

Installation - Bearing Race Fracture Position

Note: ALWAYS replace elastic-lined nuts with new

elastic-lined nuts to ensure proper fastening.

5. Move the cylinder (Fig. 5-6, 7-Front or 15-Rear) into

position on the axle cylinder anchor (8). Insert a

cylinder-mount pin (9) through the cylinder and

cylinder anchor. Secure the cylinder-mount pin (9)

with one hex-head capscrew (10) and a new hex-

locknut (11).

6. Apply multi-purpose grease through the self-tapping

lube fitting (Fig. 5-6, 12) to lubricate the self-align

bearing (6) and the cylinder-mount pin (9).

7. Install the drive shaft assemblies (Fig. 5-6, 13-Front or

14-Rear). (Refer to Section 5.4.7, “Drive Shaft

Installation.”)

8. If reinstalling an axle previously removed from the

vehicle, position the driveshaft yoke on the axle

according to the alignment marks made earlier. If

installing a new axle, note the position of the

driveshaft yoke on the transmission. Align the

driveshaft yoke on the axle in the same plane as the

yoke on the transmission.

9. Install the wheel and tire assemblies. (Refer to

Section 5.5.4, “Installing Wheel and Tire Assembly

Onto Vehicle.”)

10. Carefully remove the jack, hoist or overhead crane

and sling supporting the axle.

11. Carefully raise the vehicle using a suitable jack or

hoist. Remove the supports from beneath the frame

and lower the vehicle to the ground.

12. Remove the blocks from the front and rear of both

tires on the other axle.

1

2

3

4

5

6

7

8

9

10

11

12

MT0820

1