SkyTrak 6042 Service Manual User Manual

Page 305

8.73

Model 6042 Legacy

Origin 7/02

Hydraulic System

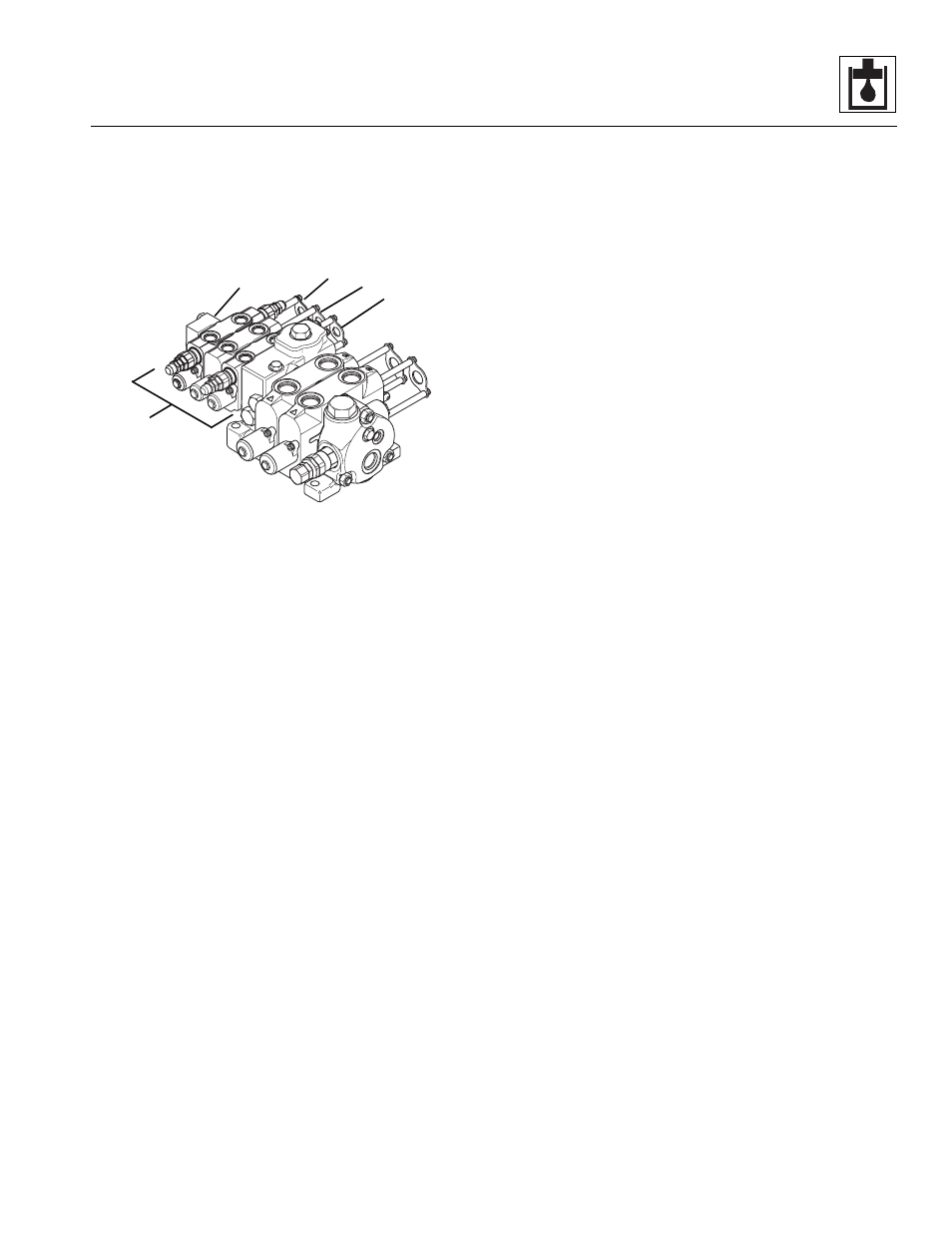

b. Main Control Valve Disassembly

This section covers disassembly of one half (Fig. 8 -41, 1)

of the main control valve, including the auxiliary

hydraulics (2), frame sway (3), attachment tilt (4) and load

sense outlet (5) sections of the main control valve.

Figure 8-41 Main Control Valve

1. To disassemble the auxiliary, frame sway,

attachment tilt and load sense outlet sections of the

main control valve (Fig. 8-40, 1), remove the

nuts (2 and 66) from the end of the tie

rods (3 and 67). Pull the tie rods out through the

sections.

2. Disassemble each section assembly as required.

Some sections include a pre-adjusted relief valve that

regulates pressure in a specific circuit.

IMPORTANT: DO NOT adjust any of the relief valve

assemblies! Tampering with a relief valve will irrevocably

alter pressure in the affected circuit, requiring re-calibration

or a new relief valve.

Disassemble the Load Sense Outlet Section

1. Carefully separate the load sense outlet section

(Fig. 8-40, 4) from the attachment tilt section (5).

Avoid dislodging or losing the spring (6) and

poppet (7) in the attachment tilt section.

2. Remove the o-ring (Fig. 8-40, 8) from between the

two sections.

3. Remove the shut-off plug (Fig. 8 -40, 9) and

o-ring (10) from the load sense outlet section (4).

Disassemble the Attachment Tilt Section

1. Carefully separate the attachment tilt section

(Fig. 8-40, 5) from the frame sway section (11). Avoid

dislodging or losing the shuttle (12), spring (13) and

poppet (14) in the frame sway section.

2. Remove the o-ring (Fig. 8-40, 15) from between the

two sections.

3. Remove the spring (Fig. 8 -40, 6) and poppet (7)

from the attachment tilt section (5).

4. Remove both socket head capscrews (Fig. 8-40, 24)

securing the cable retainer assembly (22) to the

attachment tilt section (5).

5. Remove the retainer (Fig. 8-40, 25), both

sleeves (26), another retainer (25), wiper (27) and

o-ring (28) from the cable retainer assembly (22).

6. Remove both socket head capscrews (Fig. 8-40, 29)

securing the end mechanism (23) to the attachment

tilt section (5).

7. Remove the spool cap (Fig. 8-40, 30), retainer (25),

spool end (31), o-ring (36), spring seat (32),

spring (33), another spring seat (32), wiper (34) and

o-ring (35) from the end mechanism (23).

Disassemble the Relief Valve

The relief valve assemblies (Fig. 8-40, 43) are part of the

attachment tilt section. The valves are preset at

3,250 ±50 psi (224 ±3,5 bar).

Note: If the vehicle includes auxiliary hydraulics, there

will be relief valve assemblies (Fig. 8-40, 16) on the

auxiliary hydraulics section also. These valves are

preset at 3,250 ±50 psi (224 ±3,5 bar).

1. Remove the relief valve (Fig. 8-40, 43) and

o-ring (44) from the applicable section assembly.

2. Grip the relief valve body (Fig. 8-40, 45) with a

suitable tool and use another tool to remove the

nut (46), revealing an o-ring (47) and the adjustment

screw (48).

3. Carefully remove the plug (Fig. 8-40, 49),

spring (50) and pilot poppet (51).

4. Remove the large o-ring (Fig. 8-40, 52), back-up

ring (53), small o-ring (54), large spring (55), small

spring (56), piston (57), o-ring (58), back-up ring (59)

and relief valve poppets (60 and 61).

MA10,0200

1

2

3

4

5