Fig. 8-75, Be (fig. 8-75, Fig. 8-75, 6) – SkyTrak 6042 Service Manual User Manual

Page 345

8.113

Model 6042 Legacy

Origin 7/02

Hydraulic System

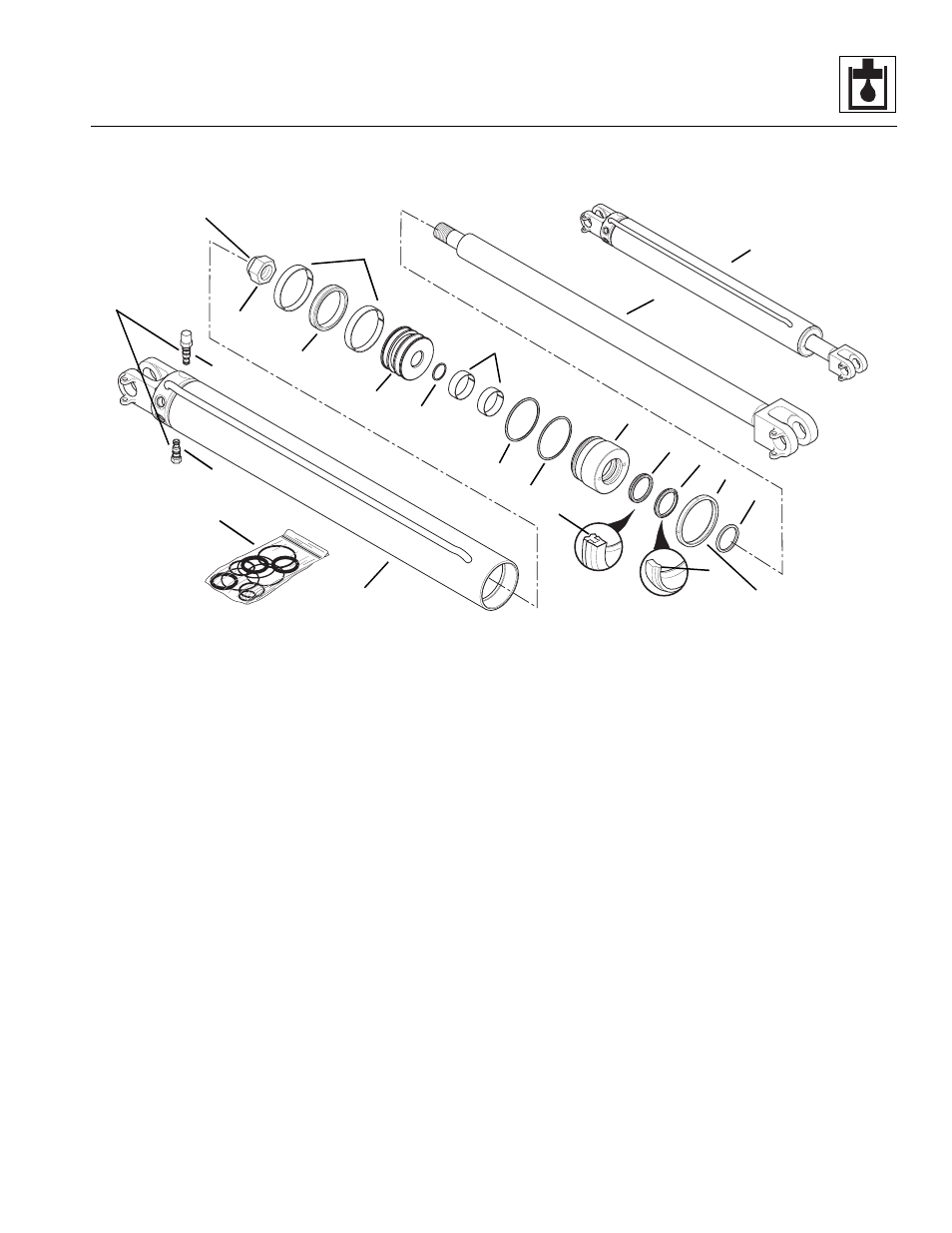

Figure 8-75 Lift/Lower Cylinder Components

IMPORTANT: When sliding the rod and piston assembly

into the tube, prevent the threaded end of the tube from

damaging the piston (Fig. 8-75, 8). Keep the rod

centered within the tube to help prevent binding.

6. Carefully pull the rod (Fig. 8-75, 5) with all

attachments straight out of the tube (2).

7. Fasten the rear of the rod in a soft-jawed vise and

put a padded support below and near the threaded

end of the rod to help prevent damage to the rod.

8. Remove the locknut (Fig. 8-75, 9) from the rod (5).

The nut was installed with Loctite #271 (red) and

torqued to 1,750-2,000 lb-ft (2.373-2.712 Nm).

Note: It may be necessary to apply heat to break the

bond of the sealant between the locknut (Fig. 8-75, 9)

and the rod (5) before the piston (8) can be removed.

Some parts of cylinders are sealed with a special organic

sealant and locking compound.

Before attempting to disassemble these parts, remove

any accessible seals from the area of the bonded joint.

Wipe off any hydraulic oil and heat the joint uniformly to

break the bond. A temperature of 300-400° F (149-204° C)

will destroy the bond. Avoid overheating or the parts may

become distorted or damaged. Apply sufficient torque or

pressure for removal while the parts are still hot.

Breakdown of sealant will leave a white, powdery

residue on threads and parts. Clean the residue away

with a soft brass wire brush prior to reassembly, and

wipe with Loctite “T” cleaner before reinstallation.

9. Remove the piston (Fig. 8-75, 8) from the rod (5).

10. Remove both precision wearbands (Fig. 8-75, 10)

and the capped T-seal (11) from the piston (8).

Note: The T-seal actually consists of four components: a

wide, flexible inner band, the flexible T-seal band itself,

and two supportive split caps that mount on either side of

the “T” itself.

MA7071

8

6

11

9

13

12

20

17

18

1

5

21

2

4

3

14

15

16

7

10

Torque to

30-35 lb-ft

(41-47 Nm)

Torque to

300-400 lb-ft

(407-542 Nm)

Apply Loctite #271 to

Threads and Torque

to 1,750-2,000 lb-ft

(2.373-2.712 Nm)

19