To section, 7, “lift/lower cylinder.”), 7 lift/lower cylinder – SkyTrak 6042 Service Manual User Manual

Page 344: Warning

Hydraulic System

8.112

Model 6042 Legacy

Origin 7/02

8.13.7

Lift/Lower Cylinder

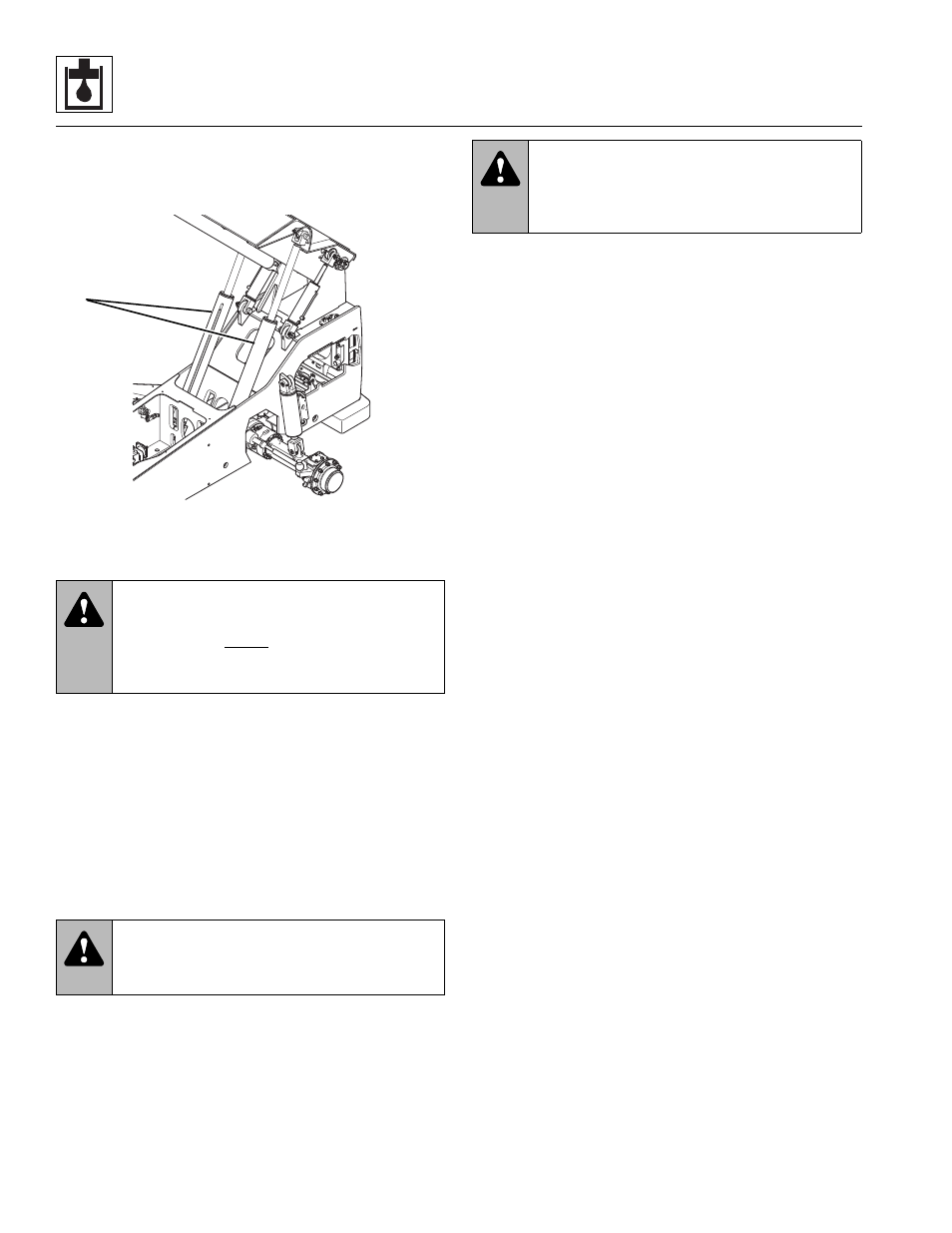

The lift/lower cylinders (Fig. 8-74, 1) are anchored to the

underside of the outer boom and to the vehicle frame.

Figure 8-74 Lift/Lower Cylinders

a. Lift/Lower Cylinder Removal

1. Park the vehicle on a firm, level surface, fully retract

all hydraulic cylinders, ground the attachment (if

any), place the travel select lever in (N) NEUTRAL,

place the neutral lock lever in the (N) NEUTRAL LOCK

position, engage the park brake switch, raise and

support the boom to allow removal of the lift/lower

cylinder and shut the engine OFF.

2. Place an Accident Prevention Tag on both the

ignition key switch and the steering wheel, stating

that the vehicle should not be operated. Refer to

Section 1.5, “Accident Prevention Tag Usage.”

3. Unlock and open the rear door. Allow the hydraulic

fluid to cool.

4. Label or otherwise mark the lift/lower cylinder hydraulic

hoses. Disconnect and cap all hoses and fittings.

5. Attach a sling to the lift/lower cylinder and to a

suitable hoist or overhead crane. Support the lift/

lower cylinder in the sling.

6. Remove the locknut, capscrew and rod end mount pin

from the cylinder. Allow the cylinder to retract so that

it can clear the mounting bracket on the outer boom.

7. Remove the locknut, capscrew and base end mount

pin from the cylinder.

8. Safely and carefully, remove the lift/lower cylinder

from the vehicle. Wipe up any hydraulic fluid spillage

in, on, near and around the vehicle.

b. Lift/Lower Cylinder Disassembly

Note: An additional o-ring may be included at the base

of the cylinder rod. This additional o-ring may be discarded,

as it served only in a temporarily protective role.

1. Clean the lift/lower cylinder (Fig. 8-75, 1) with a

suitable cleaner. Remove all dirt, debris and grease

from the cylinder.

IMPORTANT: Avoid using excess force when clamping

the cylinder in a vise. Apply only enough force to hold the

cylinder securely. Excessive force can damage the

cylinder tube (Fig. 8-75, 2).

2. Secure the lift/lower cylinder in a soft-jawed vise or

other acceptable holding equipment if possible.

3. Slowly remove the counterbalance valve (Fig. 8-75, 3)

and pilot-operated check valve (4) from the tube (2).

IMPORTANT: DO NOT tamper with or attempt to reset

the counterbalance valve cartridge. If adjustment or

replacement is necessary, replace the counterbalance

valve with a new part.

4. Extend the rod (Fig. 8-75, 5) as required to allow

access to the base of the cylinder.

IMPORTANT: Protect the finish on the rod at all times.

Damage to the surface of the rod can cause seal failure.

5. Using a pin spanner wrench, unscrew the locking collar

(Fig. 8-75, 6) from the tube (2). The locking collar

was originally torqued to 300-400 lb-ft

(407-542 Nm), so a considerable amount of force is

required. Carefully slide the locking collar (6) and the

head gland (7) down along the rod toward the eyelet

end, away from the cylinder tube (2).

WARNING:

DO NOT get under a raised

boom unless the boom is blocked up. Always

block the boom before doing any servicing that

requires the boom to be up. Unexpected lowering

of the boom may cause death or serious injury.

WARNING:

Hot hydraulic fluid can

cause severe burns. Wait for hydraulic fluid to

cool before servicing any hydraulic component.

MA9290

1

WARNING:

Escaping hydraulic fluid

under pressure can penetrate the skin, causing

death or serious injury. Relieve hydraulic pressure

before servicing any hydraulic component.