10 swing carriage (optional) – SkyTrak 6042 Service Manual User Manual

Page 357

8.125

Model 6042 Legacy

Origin 7/02

Hydraulic System

IMPORTANT: Use a suitable installation tool or

compression sleeve to help prevent twisting or damaging

the seals and o-rings when installing the piston

(Fig. 8-82, 12) and head gland (9) into the cylinder.

When sliding the rod and piston assembly in the tube,

DO NOT damage the piston by scraping it against the

threads in the tube. Keep the rod in line with the tube to

prevent binding.

14. Keep the rod (Fig. 8-82, 10) straight and carefully

insert the rod into the tube (2). Avoid scratching,

nicking or damaging the tube while installing the rod.

15. Begin threading the head gland (Fig. 8-82, 9) into

the tube (2). Place the locking insert (8) in its hole in

the head gland threads just before the hole is

threaded into the tube. Use a suitable pin spanner

wrench to thread the head gland (9) completely into

the tube (2). Torque the head gland to 300-400 lb-ft

(407-542 Nm).

16. Using new oiled o-rings, thread the two pilot-operated

check valves (Fig. 8-82, 3), the pressure reducing

valve (4) and the five solenoid valves (5 and 6) into

the manifold block (7). Torque the five solenoid

cartridges (5 and 6) to 25-30 lb-ft (34-41 Nm).

Torque the check valves (3) and the pressure

reducing valve (4) to 35-40 lb-ft (47-54 Nm). Place

the solenoid coils on the cartridges and torque the

solenoid nuts to 4-6 lb-ft (5-8 Nm).

17. Test the cylinder at low operating pressure [100 psi

(7 bar)] to verify that the piston and rod move freely

in both directions.

18. Increase the operating pressure to the maximum for

the cylinder [4,000 psi (275 bar)] and check for

external leakage and for free movement in both

directions.

19. Retract the piston fully.

f.

Stabilizer Cylinder Installation

1. Lubricate the cylinder pins with multi-purpose,

lithium-based grease.

2. Use a sling and hoist or other suitable lifting device

to help install the cylinder. Orient the cylinder with

the cylinder eyelet on top and the rod eyelet on the

bottom.

3. Install the upper cylinder pin. Drive the lubricated

cylinder pin through the cylinder eyelet, frame mount

and self-aligning bearing. Secure the pin with a

capscrew and hex-locknut. Torque to 18 lb-ft (24 Nm).

4. Use new flat-faced oiled o-rings when installing the

upper and lower hydraulic hoses. Install and tighten

the hoses onto the appropriate fittings on the

manifold.

g. Stabilizer Cylinder Pressure Checking and

Circuit Bleeding

1. Attach a 4,000 psi (276 bar) gauge to the test fitting

on the main control valve to test the system

pressure. Pressure readings should be

3,000 ±100

psi (207 ±7 bar). Refer to Section 8.7, “Hydraulic

System Testing.” To check the cylinder pressure,

consult the factory.

2. Start the vehicle. Level the frame.

3. Sway the vehicle fully left. Hold the joystick at full

sway left for several seconds, then sway the vehicle

fully right and hold the joystick at full sway right for

several seconds. Observe the readings on the gauge

during the frame sway operations.

4. Level the frame. While leveling the frame, check the

pressure reading on the gauge.

5. Repeat Steps 3-4 five times.

8.13.10

Swing Carriage (Optional)

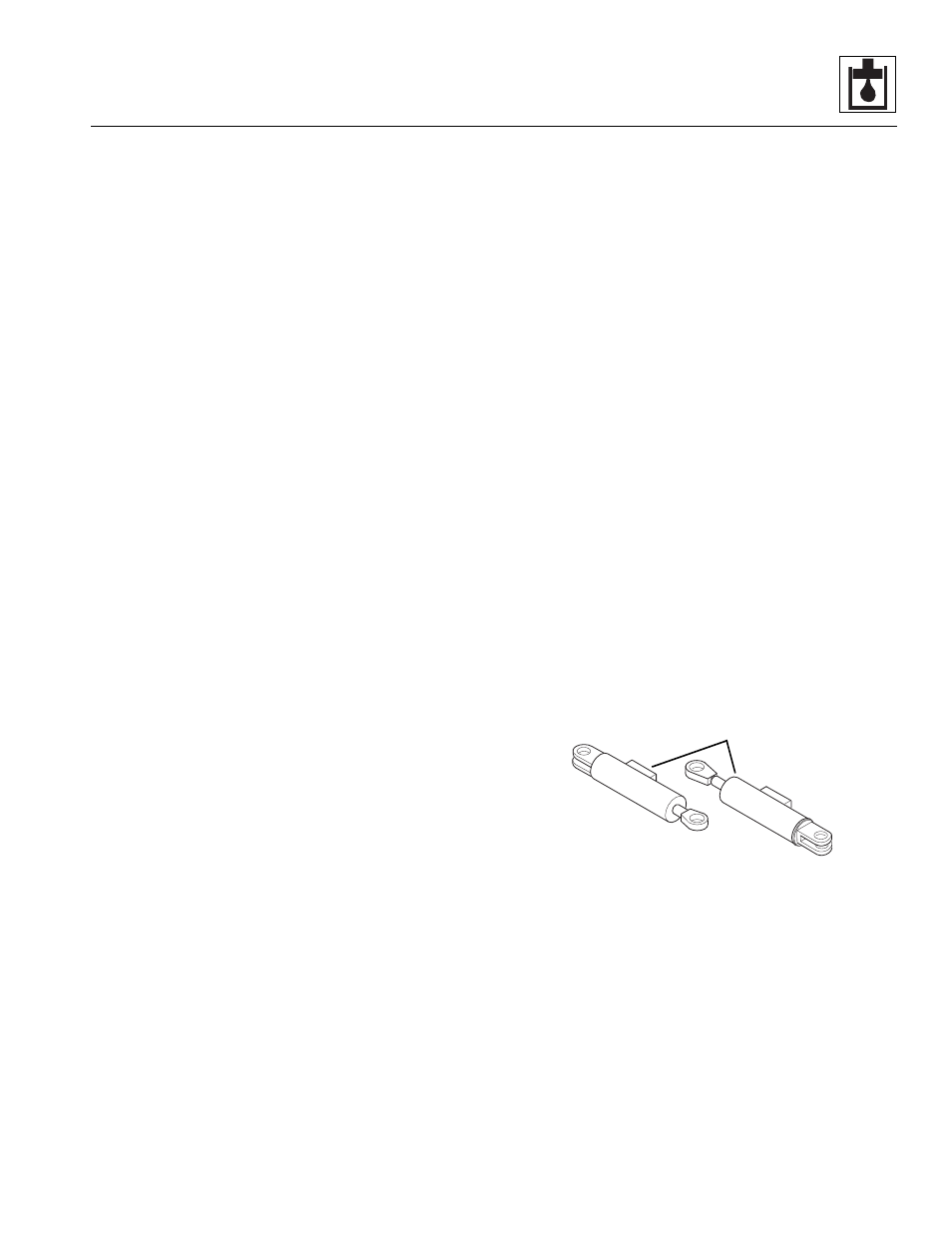

The optional swing carriage provides a way to swing the

carriage attachment from side-to-side. The swing carriage

includes two cylinders (Fig. 8-83, 1) that operate together

to provide the side-to-side motion.

Figure 8-83 Swing Carriage Cylinders

a. Swing Carriage Cylinder Removal

1. Level the boom (place the boom in a horizontal

position).

2. Swing the carriage to the centered position.

3. Lower the boom until the carriage is resting firmly on

the ground.

4. Place the travel select lever in (N) NEUTRAL, place

the neutral lock lever in the (N) NEUTRAL LOCK

position, engage the park brake switch and shut the

engine OFF.

MT2450

1