SkyTrak 6042 Service Manual User Manual

Page 54

Boom

3.8

Model 6042 Legacy

Origin 7/02

Note: If replacing the inner boom assembly with a new

inner boom, the quick attach assembly and the attachment

tilt cylinder should be removed at this time.

If the inner boom is not to be replaced, the quick attach

assembly and attachment tilt cylinder can remain in

place. Proceed to Step 34.

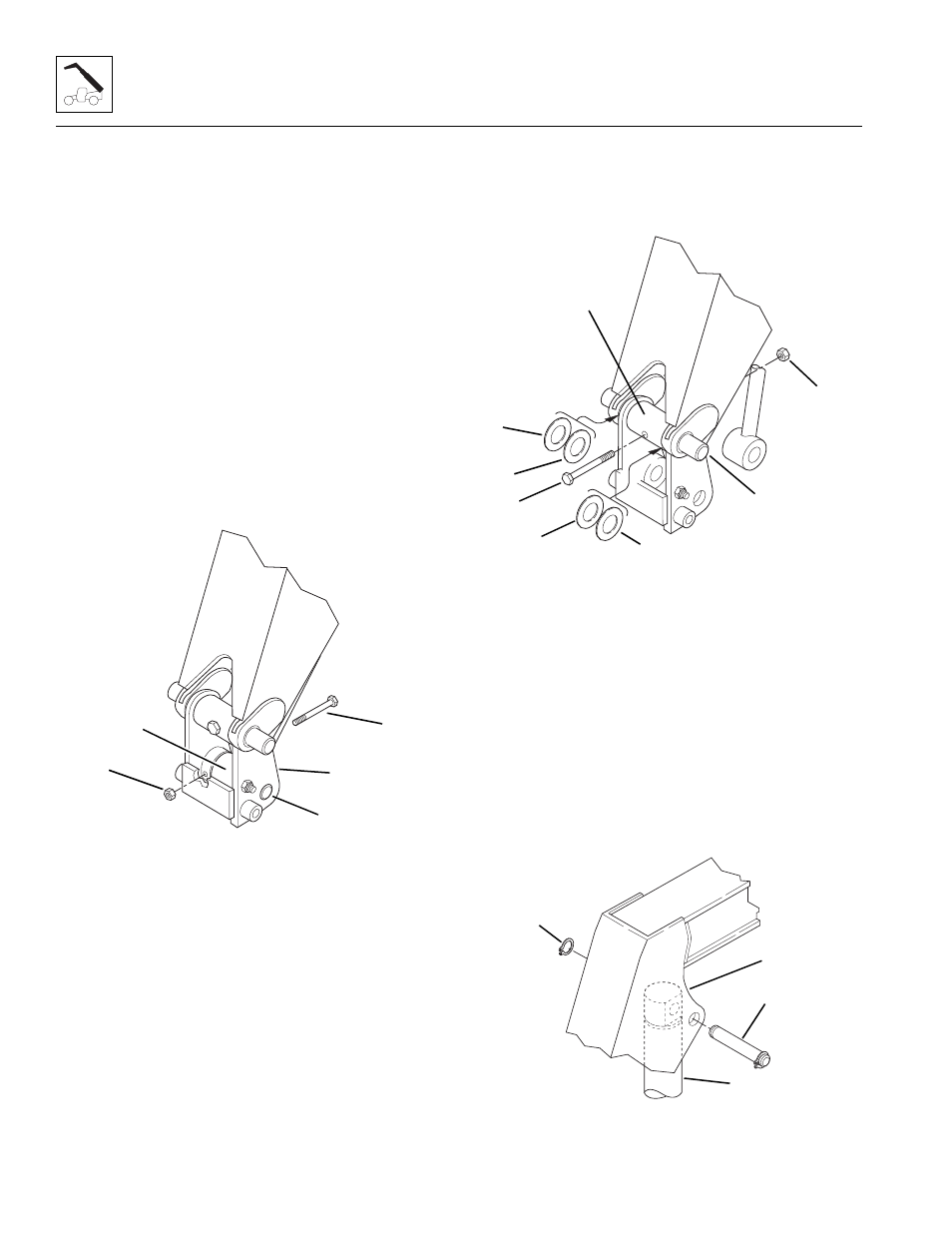

25. Remove the elastic locknut (Fig. 3-13, 1) and

capscrew (2) holding the attachment tilt cylinder rod

end pin (3) to the quick attach assembly (4). Save

the capscrew and discard the elastic locknut.

26. Support the rod end of the attachment tilt cylinder

(Fig. 3-13, 5). Use a brass punch and a rawhide

hammer to remove the rod end pin (3) from the quick

attach assembly.

27. Inspect the pin (Fig. 3 -13, 3) for nicks or surface

corrosion. Use fine emery cloth to fix minor nicks or

corrosion. If damaged and if it cannot be repaired,

the pin must be replaced.

Figure 3-13 Attachment Tilt Cylinder Rod

End Pin Removal

28. Remove the elastic locknut (Fig. 3-14, 1) and

capscrew (2) holding the quick attach pivot pin (3) to

the quick attach assembly (4). Save the capscrew

and discard the elastic locknut. Place a support

under the quick attach assembly to prevent it from

dropping when the pivot pin is removed.

29. Use a brass punch and a rawhide hammer to

remove the quick attach pivot pin (Fig. 3 -14, 3) from

the quick attach assembly and the bushings in the

gooseneck. Record the location and quantity of the

shim washers (5 and 6) as the pin is being removed.

Save the washers (5 and 6) from each side of the

quick attach.

30. Inspect the pin for nicks or surface corrosion. Use

fine emery cloth to repair minor nicks or corrosion. If

damaged and if it cannot be repaired, the pin must

be replaced.

Figure 3- 14 Quick Attach Pivot Pin Removal

Note: The attachment tilt cylinder is heavy. Use a hoist

and sling to support the attachment tilt cylinder when the

base end pin is removed.

31. Remove the retaining ring (Fig. 3-15, 1) from one

side of the base end pivot pin (2). Save the retaining

ring. Use a brass punch and a rawhide hammer to

remove the base end pivot pin from the inner boom

gooseneck (3).

32. Inspect the pin for nicks or surface corrosion. Use

fine emery cloth to repair minor nicks or corrosion. If

damaged and if it cannot be repaired, the pin must

be replaced.

Figure 3-15 Attachment Tilt Cylinder Removal

MH0940

1

5

2

4

3

~

MH0950

5

4

3

2

1

5

6

6

~

MH0960

1

2

3

4