West Control Solutions KS98-1 User Manual

Page 283

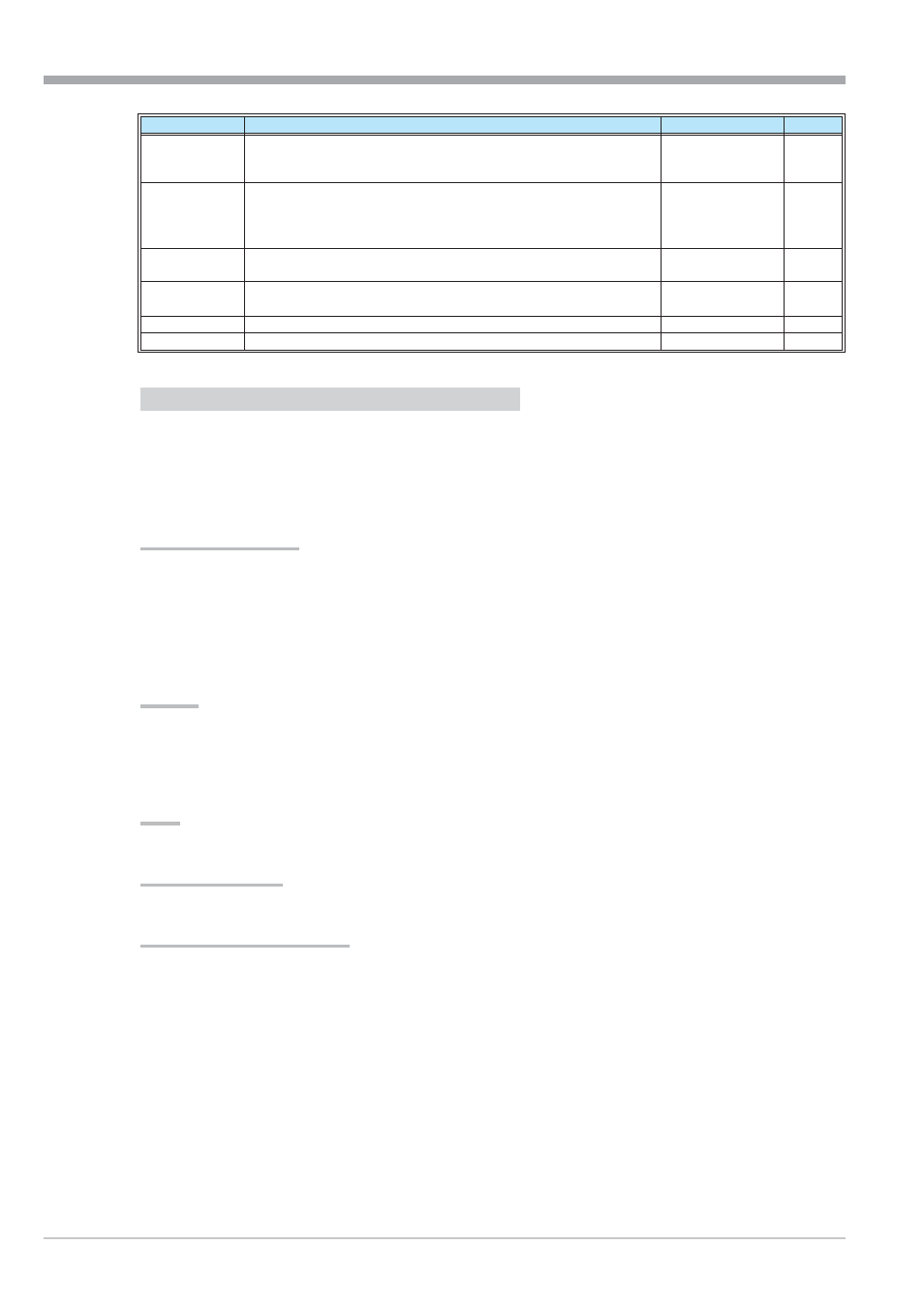

Configuration Description

Values

Default

Type

0...20 mA

0...20mA

t

4...20 mA

4...20mA

Transducer 0...1000 [

Pot.trans.

Fail

Fail function off

disabled

Digital output

fail = 1, y1 = x100

Upscale

t

Digital output

fail = 1, y1 = x0

Downscale

Digital output

fail = 1, y1 = XFail

Subst.val.

Xkorr

Measured value correction off

off

t

Measured value correction adjustable

on

x0

Physical value at 0%

only effective with standard

signals (0/4..20mA or 0/2..10V)

-29999 ... 999 999

0

x100

Physical value at 100%

-29999 ... 999 999

100

XFail

Substitute value with sensor error

-29999 ... 999 999

0

Tfm

Filter time constant [s]

0 ... 999 999

0,5

Input value conditioning

Before the pre-filtered (time constant ...; limiting frequency

...) analog input signals are available as digitized measure-

ment values with physical quantity, they are subjected to ex-

tensive input value processing.

Input circuit monitor

q

Transducers are monitored for break and short circuit.

q

Current signals Out-of-range monitoring (I > 21,5 mA) with current signals (0/4...20 mA) and short-cir -

cuit monitoring (I < 2 mA) with “life zero” signals are provided.

Sensor errors are output as digital output (

fail). In case of error, statuses ‘Upscale‘, ‘Downscale‘ or

‘

Subst.val‘ defined in the configuration (Fail) can be used for the input circuit.

Scaling

The mA standard signals are scaled according the the physical measuring range of the transmitter (

x0, x100). With

potentiometric transducer measurements, “calibration” is according to the proven method. Bring the transducer to start

and then to end position and “calibrate” to 0 % or 100 % by key pressure. The calibration principle corresponds to

scaling, whereby gradient and zero offset are calculated automatically by the firmware.

Filter

A 1st order filter is adjustable in addition to filtering in the analog part of each input signal.

Sampling intervals

The sampling interval for INP6 is 400ms.

Measured value correction

Measured value correction can be used for various types of measurement correction.

Pre-requisite: configuration

XKorr = ein

In most cases, the relative rather than the absolute accuracy and reproducibility are of interest, e.g.:

– measurement error compensation in a working point ( control)

– minimization of linearity errors within a limited operating range (variable )

– correspondence with other measuring facilities (recorders, indicators, PLCs, ...)

– compensation of sensor, transmitter, etc. sample differences.

The measured value correction is designed both for zero offset, gain matching and for both. It corresponds to scaling

mx+b, with the difference that the KS 98-1 firmware calculates gain m and zero offset b from the defined value pairs for pro-

cess value (

x1in; x2in) and (x1out; x2out) of two reference points.

Inputs

9499-040-82711

III-283

AINP6 ( analog input 6 (No. 115))