Iii-16.5 optimizing the controller 240, Optimizing the controller 240, Characteristic values 240 – West Control Solutions KS98-1 User Manual

Page 240: Process characteristics 240, Process characteristics 240,263, Iii-16.5 optimizing the controller, Process characteristics, Characteristic values of the controllers

III-16.5

Optimizing the controller

Process characteristics

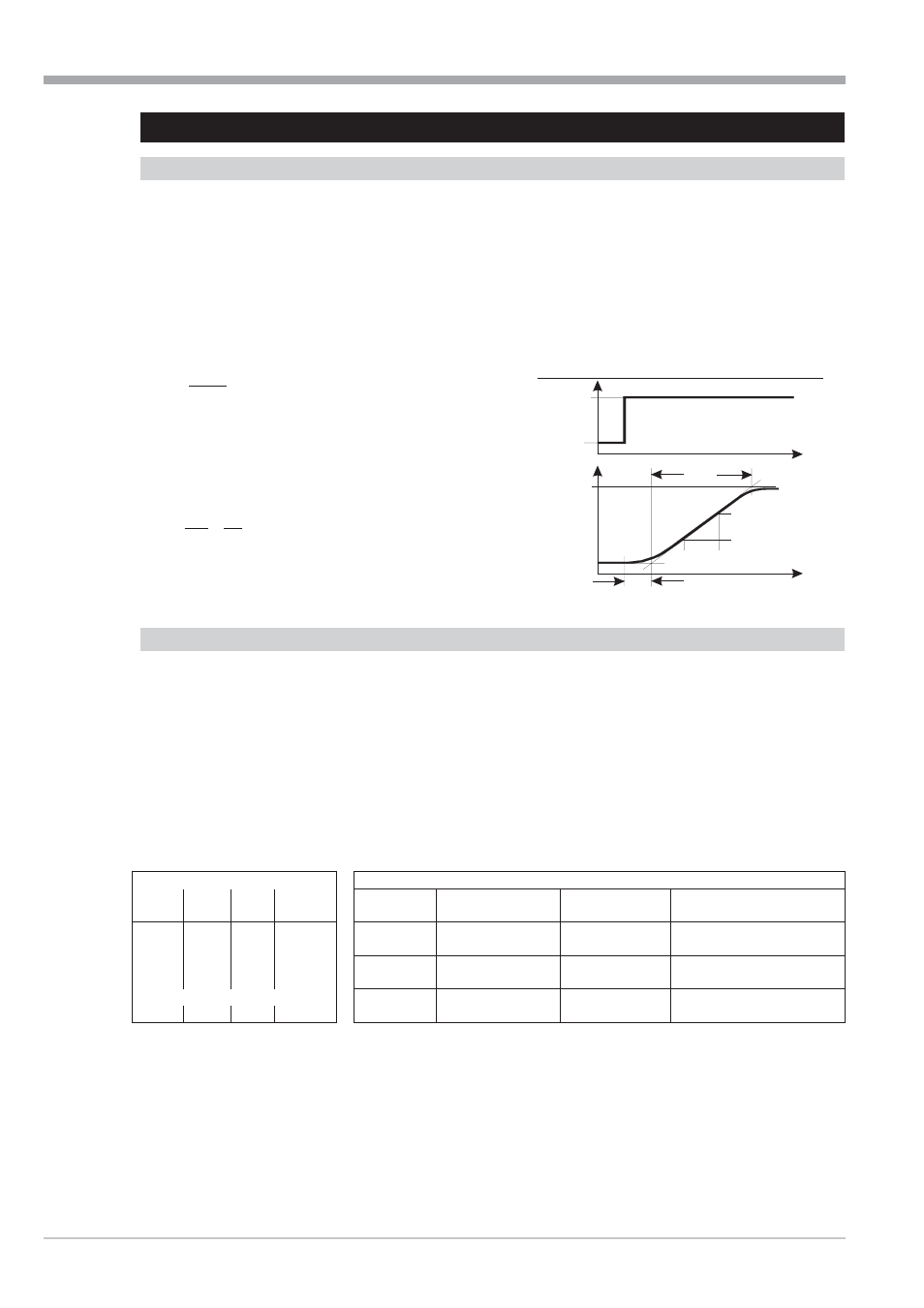

Characteristics are determined automatically by the controller during self-tuning and converted into control parame -

ters. In exceptional cases, however, manual determination of these process characteristics may be necessary. For this,

the response of process variable x after a step change of correcting variable y can be used (see Figure below).

Usually, it is not possible to plot the complete response curve (0 to 100 %), as the process must be kept within certain

limits.

The maximum rate of increase v

max

can be determined from the values T

g

and x

max

(complete step response) or

Dt and

Dx (partial step response).

K

Tu

V

Xh

=

Ч Ч

max

%

100

y = correcting variable

Y

h

= control range

Tu = delay time (s)

Tg = recovery time (s)

V

X

Tg

x

t

max

max

=

=

D

D

= max. rate of increase of process value

X

max

=

maximum process value

X

h

=

control range =

x100 - x0

Characteristic values of the controllers

Generally, quick line-out to the without oscillation is required.

Dependent of process, different control actions should be used.

w

Processes with good controllability (K < 10%) can be controlled by means of PD controllers,

w

Processes with medium controllability (K = 10...22%) can be controlled with PID controllers and

w

Processes with bad controllability (K > 22%) can be controlled with PI controllers.

The control parameters can be determined from the calculated values of delay time T

u

, max. rate of inrease v

max

, con-

trol range X

h

and characteristic value K according to the formulas. For more exact adjustment, see the hints given in

the table of parameter adjustment effects. Increase Xp if line-out oscillates.

Formulas

Parameter adjustment effects

Action

Xp[%]

Tv[s]

Tn[s]

Setting

Control

Line-out of distur-

bances

Start-up behaviour

(D)PID

1,7 K

2 Tu

2 Tu

Xp

higher

Increased damping

Slower line-out

Slower reduction pf energy

PD

0,5 K

Tu

Î = 0000

lower

Reduced damping

Faster line-out

Faster reduction of energy

PI

2,6 K

0

6 Tu

Tv

higher

Reduced damping

Faster response

Earlier reduction of energy

P

K

0

Î = 0000

lower

Increased damping

Slower response

Later reduction of energy

3-point stepping controller PID

Tn

higher

Increased damping

Slower line-out

Slower reduction of energy

1,7 K

Tu

2 Tu

lower

Reduced damping

Faster line-out

Faster reduction of energy

Controller

9499-040-82711

III-240

Optimizing the controller

Tu

Tg

t

{X

{t

x

y

100%

0%

Y

h

t

X

max

Fig.: 60 step response