Logic configuration – Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 68

68

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Chapter 3

FANUC CNC Configuration

Logic Configuration

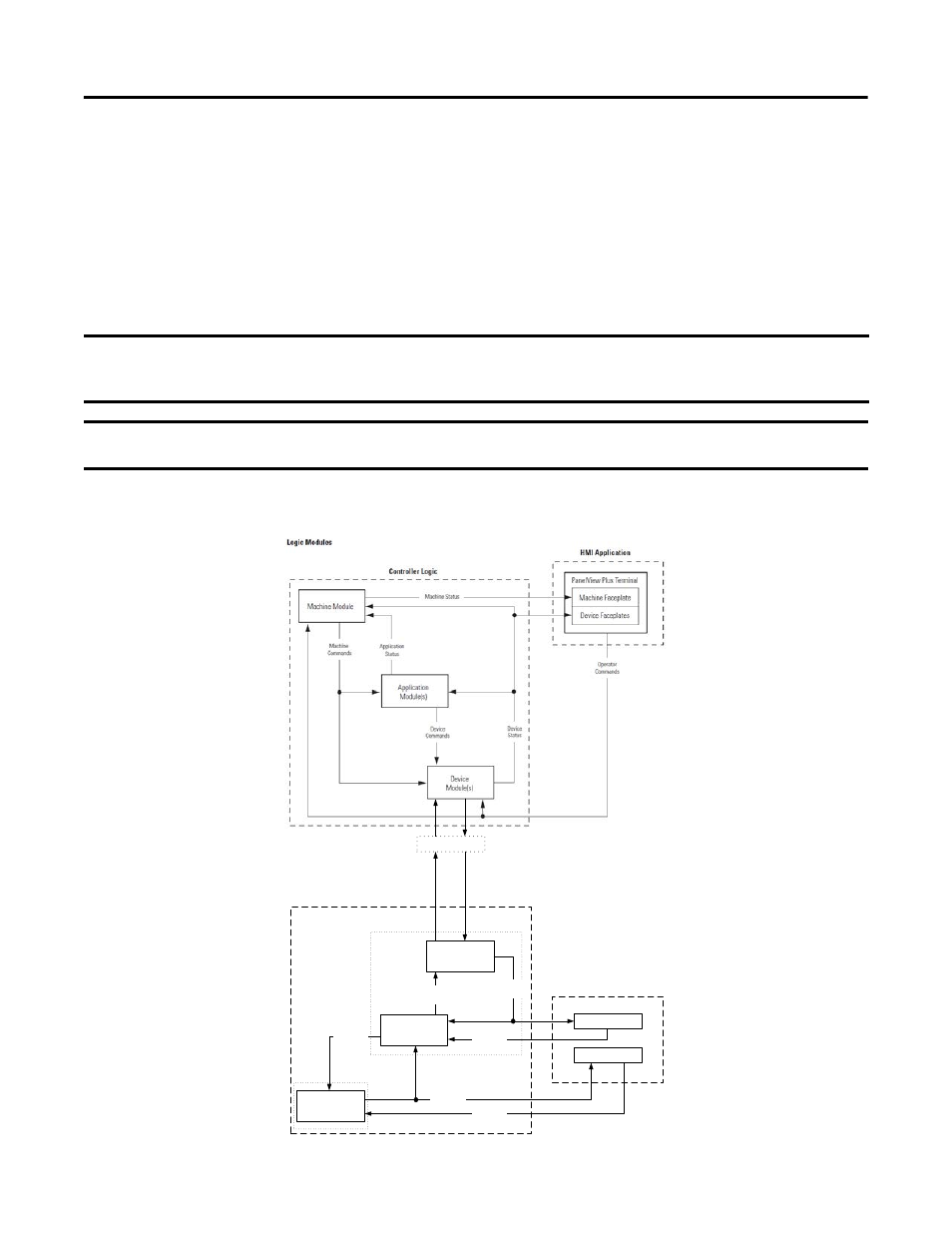

In this chapter you use the preconfigured PMC logic files and edit them specifically for your application. The

toolkit provides a preconfigured PMC file with application and device modules that significantly speed-up your

application logic development. An initial I/O configuration is provided as well, as an example only.

To assist you in understanding how to best use the preconfigured logic files, the CNC Work Cell application is

used as an example in all of the logic configuration steps.

In this example, the PLC is controlling the machining centers, sending commands over the EtherNet/IP network

to the FANUC CNC devices.

IMPORTANT The overall machine CNC functionality and configuration is not being detailed or explained here. The CNC Machining

Accelerator Toolkit, and this quick start, provide the framework to communicate with the Rockwell Automation

GuardLogix supervisory controller.

IMPORTANT In this example, there is a supervisory PLC that manages an entire work cell consisting of a gantry, and two machining

centers. This PMC program is for one of the machining centers, but could be used interchangeably as a starting point.

Device

Module(s)

Application

Module(s)

Machine Module

CNC

PMC

MDI Panels

Device

Status

Device

Commands

LCD Display

Machine

Status

Operator

Commands

Operator

Commands

CNC/PMC Logic

CNC Operator Panels

Application

Commands

PLC AOP