Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 232

232

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Appendix A

Logic Program Overview

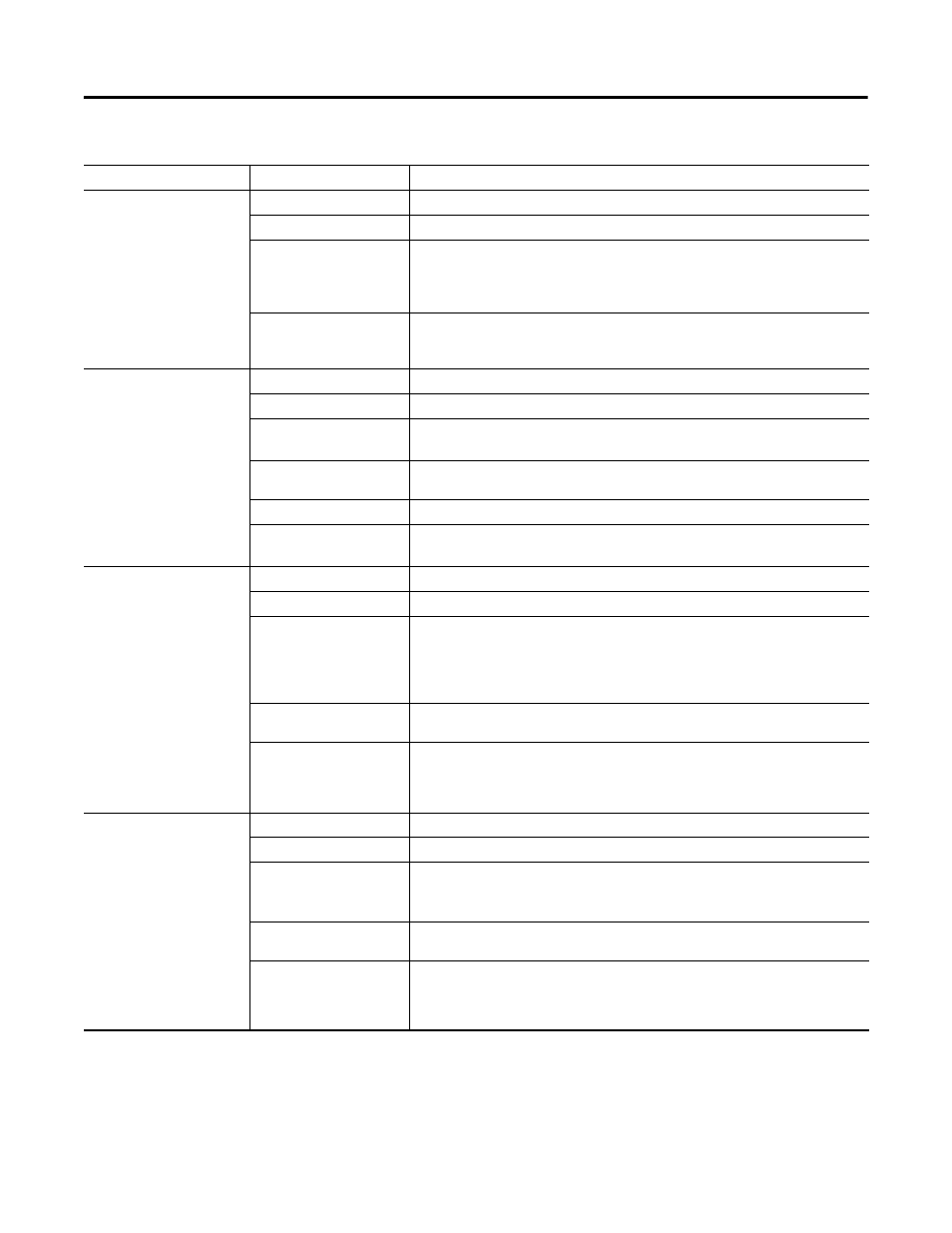

Table 13 - Module Routine Overview

Logic Module Type

Routine

Function

Machine

R00_Main

Dispatch routine, calls all of the other routines in the program.

R01_PowerUp

Initializes parameters following powerup or controller first scan.

R02_Monitor

• Summarizes the status from all of the dependent modules (for example, application and device

modules).

• Detects Abort and/or Stop conditions.

• Provides machine status information to HMI terminal.

R03_Control

• Provides main interface with HMI terminal requests (for example, Start/Stop/Clear Faults

pushbuttons).

• Contains the state machine logic.

Application

R00_Main

Dispatch routine, calls all of the other routines in the program.

R01_PowerUp

Initializes parameters following powerup or controller first scan.

R02_Monitor

• Summarizes the status for the application module (for example, OK, Ready, Running, Stopped).

• Detects module faults (for example, Failed to RESET, Failed to RUN).

R03_Control

Receives machine commands and initiates the corresponding sequences (for example, RESET, RUN and

STOP sequences).

R04_Reset

Contains the RESET sequence logic, used to prepare the application to run.

R10_ApplicationCode

• Typical location for the application specific logic.

• Contains the RUN and STOP sequences.

FANUC CNC

R00_Main

Dispatch routine, calls all of the other routines in the program.

R01_PowerUP

Initializes parameters following powerup or controller first scan.

R02_Monitor

• Summarizes the status for the device module (for example, OK, Ready, Reset).

• Detects module faults (for example, Failed to RESET, Failed to CLEAR, Module Not

Ready).

• Contains the faceplate add-on instruction (Add-On Instruction) for the HMI terminal

faceplate.

R03_Control

Receives machine commands and initiates the corresponding sequences (for example,

RESET and ABORT sequences).

R04_Reset_Abort

• Contains place holder for application specific reset logic if required.

• Contains the ABORT sequence, which makes sure that the drives contained within the

module are stopped and disabled. The ABORT sequence also makes sure that other

devices are placed into a desired state.

PowerFlex

R00_Main

Dispatch routine, calls all of the other routines in the program.

R01_PowerUP

Initializes parameters following powerup or controller first scan.

R02_Monitor

• Summarizes the status for the device module (for example, OK, Ready, Reset).

• Detects module faults (for example, Failed to RESET, Failed to CLEAR, Module Not Ready).

• Contains the faceplate add-on instruction (Add-On Instruction) for the HMI terminal faceplate.

R03_Control

Receives machine commands and initiates the corresponding sequences (for example, RESET and ABORT

sequences).

R04_Reset_Abort

• Contains place holder for application specific reset logic if required.

• Contains the ABORT sequence that makes sure that the drives contained within the module are

stopped and disabled. The ABORT sequence also makes sure that other devices are placed into a

desired state.