Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 188

188

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Chapter 5

FactoryTalk View ME Configuration

7.

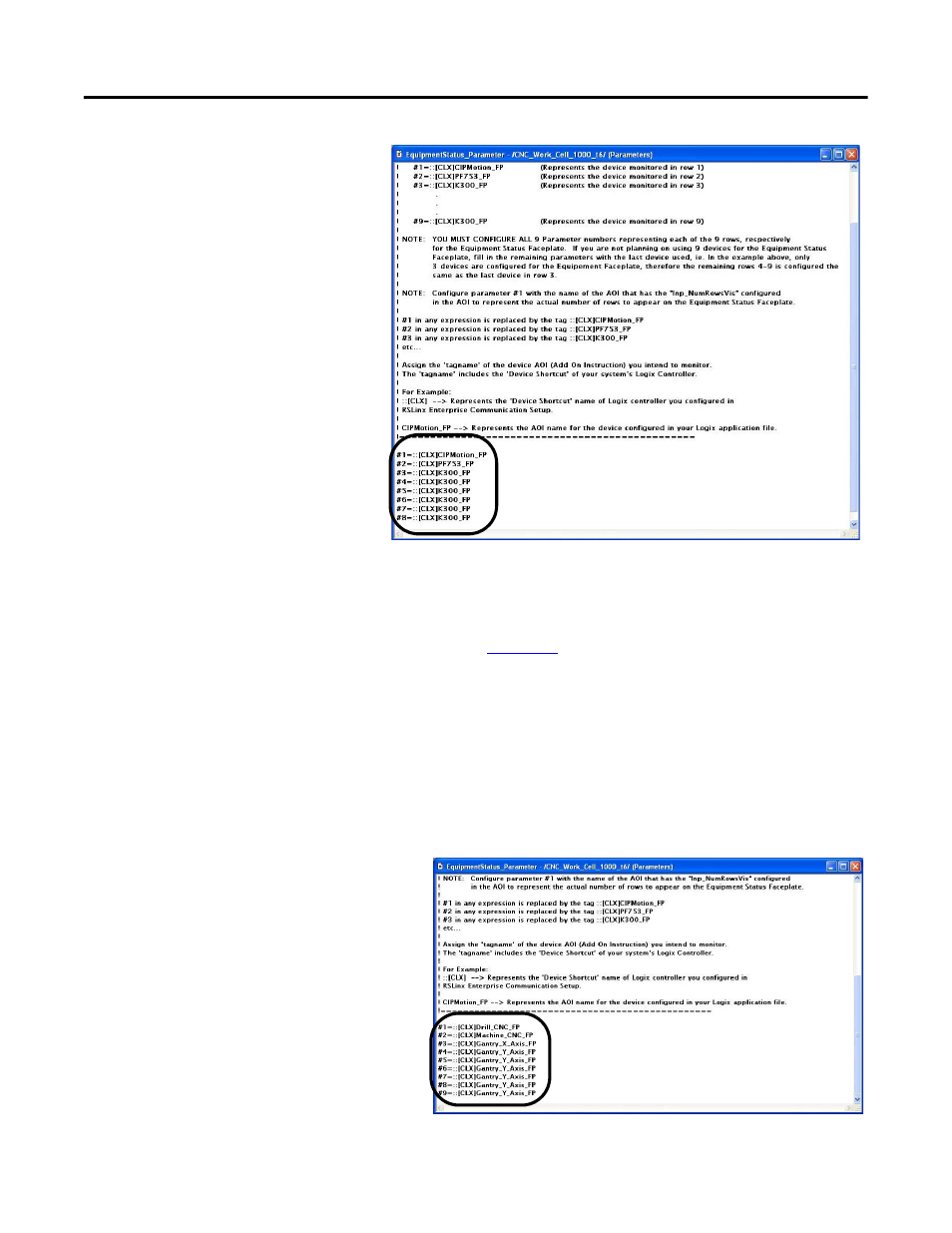

Assign device faceplate Add-On

Instruction tags to all nine

parameters.

Each parameter #1…#9 corresponds to the device Add-On Instruction tag name of each machining status

faceplate Row #1…#9. You must assign the #1 parameter to a device faceplate Add-On Instruction that includes

the Inp_NumRowsVis assignment that was configured in

The remaining parameters #2…#9 must be assigned to valid device faceplate Add-On Instruction tag names for

the machining status faceplate to operate without errors, even if corresponding machining status faceplate rows

are not being used or assigned to non-preconfigured devices. It is recommended to fill in the unused parameters

with the last valid Add-On Instruction tag name.

In the CNC Work Cell example we are only using four rows; therefore, parameter #1…#4 are assigned to the

corresponding device Add-On Instruction tags that we display in rows #1…#4.

The remaining parameters, #5…#9, are assigned

to the #4 row device Add-On Instruction tag

name, [CLX]Gantry_Y_Axis_FP, as a place

holder for those faceplate objects in the

non-visible rows #5…#9.

8.

Close the MachiningStatus_Parameter

dialog box and acknowledge the Save

Changes dialog box.