Toolkit application logic example overview, Application logic creation steps, That use application logic examples – Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 126

126

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Chapter 4

GuardLogix Configuration

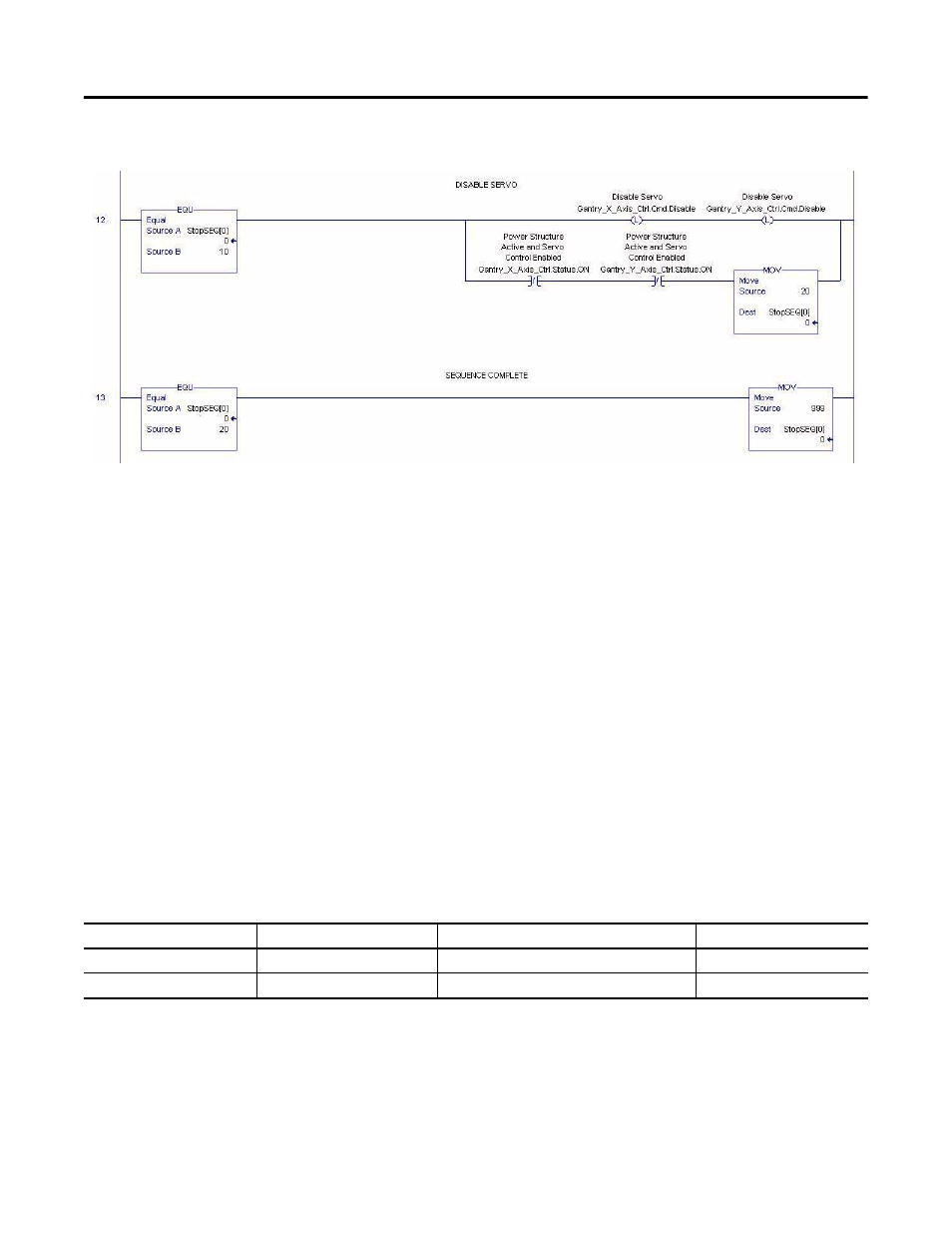

Figure 14 - Final Stop Sequential Step and Sequence Complete Example

This CNC Work Cell final stop step and complete logic example includes logic to unlatch (U) the Stopped

status, one the gantry has been confirmed to be stopped. Identical to the stop sequence template, the stop

sequence complete rung sets the StopSEQ[0] tag value to 999, which indicates the stop sequence is complete.

Application Logic Creation Steps That Use Application Logic Examples

If you are unfamiliar with the Rockwell Automation general Logix commands, Logix motion commands,

FANUC CNC parameters, and/or are seeking common application methods for creating specific application

logic, use these steps to create your specific application logic.

Toolkit Application Logic Example Overview

The toolkit provides a variety of common application logic examples designed to help you create your specific

application logic. The logic examples are organized by the device modules they support.

The CNC Work Cell example supports a combination of a simulated gantry, and two FANUC CNCs for

machining.

Table 4 - CNC Work Cell Logic Examples

Application Example

File Name

Description

Application Created From

CNC Work Cell gantry

App1_Gantry_Simulation

Simulate gantry motion

None

CNC Work Cell machine

App2_CNC_Machining

Simulate/run through CNC commands

None