Coordinated reset customization – Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 253

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

253

Logic Module Customization

Appendix B

Coordinated Reset Customization

By default, each device module is pre-programmed with reset logic that is designed to prepare the module and the

devices it contains (drives, for example) to run. For a sercos or CIP Motion axis, this might mean the reset logic

will home the axis. This approach is well suited for applications where the individual device modules reset

independently. However, some applications require multiple device modules to reset in a coordinated manner.

For example, when two or more sercos and/or CIP Motion axes are homed in sequential order to avoid

mechanical interference.

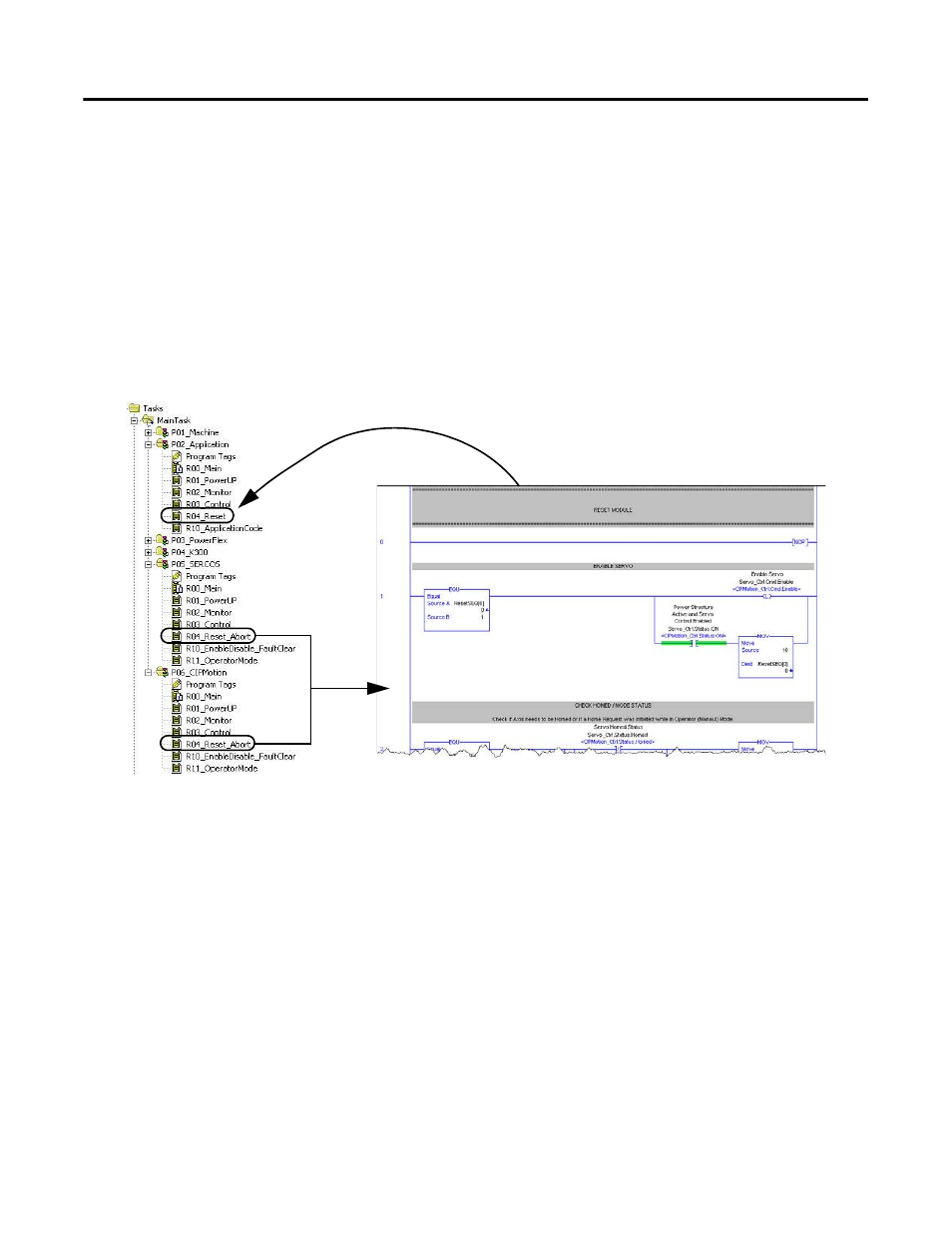

To achieve a coordinated reset, we recommend that you remove the reset-sequence logic from each of

corresponding device module R04_Reset_Abort routines and insert it into the application R04_Reset routine.

The reset logic from each device module can be blended together into a single reset sequence in the application

module. Also, your application may contain device modules that can be reset independently while others may

need a coordinated reset. In these cases, you only need to relocate the reset logic for the device modules that

require the coordinated reset.