Fault indication view – Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 223

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

223

System Application Guide

Chapter 7

Table 10 - General Status/Control Buttons

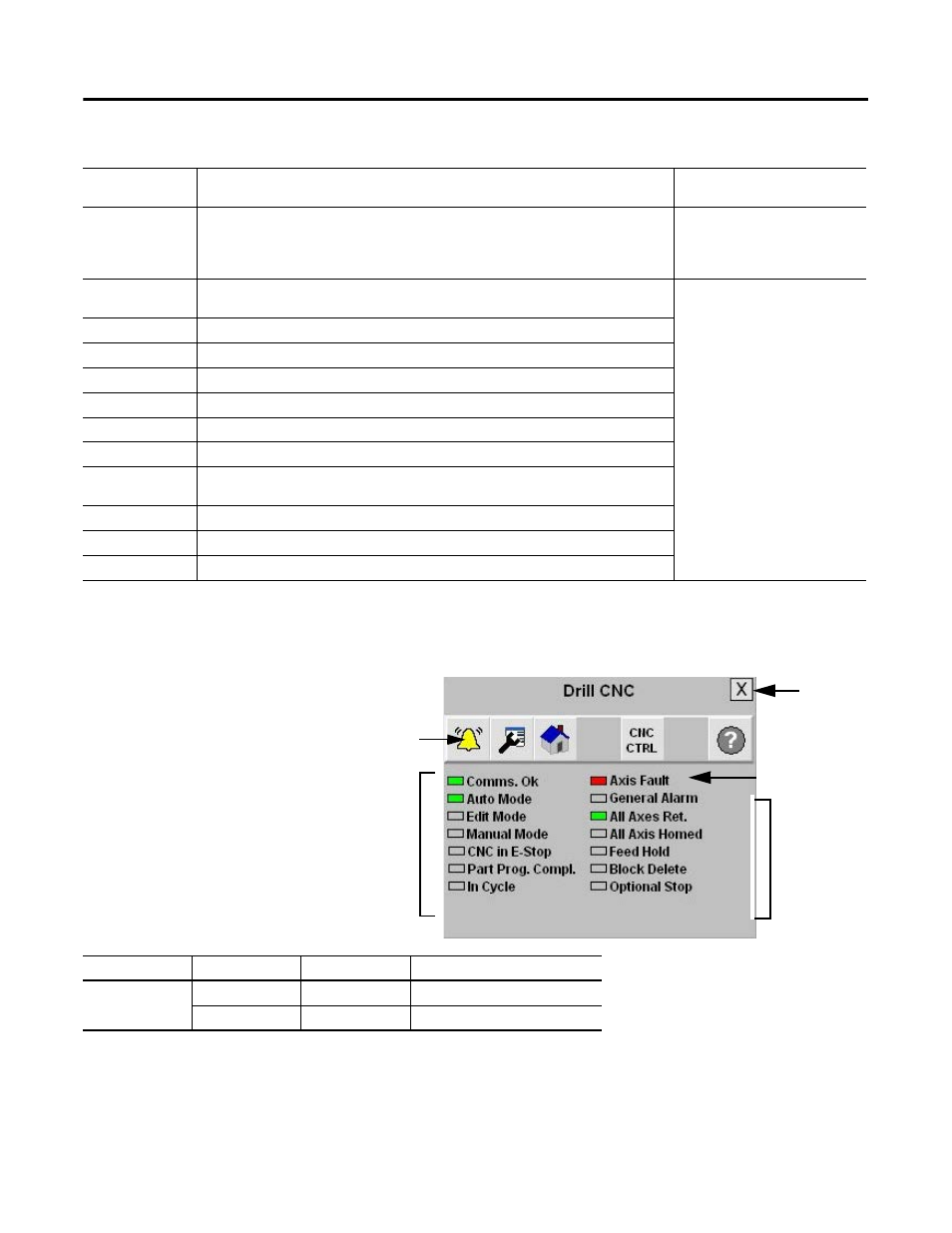

Fault Indication View

The Alarm button indicates a

CNC fault condition and

activates the fault diagnostic

views.

Table 11 - Fault Indication View

To access the detailed fault information and action displays, press the alarm button on the toolbar.

Button/Indicator

Description

Conditions Required for

Each Manual Control Button

Program/Operator

Toggles the control mode between Program and Operator mode.

Operator mode permits manual control of the drive from the faceplate. Program mode

operates the drive according to the Logix program. The active control mode is displayed on

the button.

Machine cannot be in the

STARTING or RUNNING state

Cycle Start/Cycle

Stop

Toggles the drive between the start and stop states. The active state of the drive is

displayed on the button.

Operator mode

CLR Alarms

Sends command to CNC to clear any active CNC alarms.

CLR Faults

Sends command to CNC to clear any active CNC faults.

Home

Commands the CNC to go to it's HOME position.

Block Delete

Sends the BLOCK DELETE command to the CNC.

Optional Stop

Sends the OPTIONAL STOP command to the CNC.

Feed Hold

Puts the CNC into FEED HOLD.

Unload Mch.

Sends the UNLOAD MACHINE command to the CNC, and sets commands the CNC back to

it's RETURNED position.

Gage Part

Sends the GAGE PART command to the CNC.

E. Return

Sends the EMERGENCY RETURN command to the CNC, HOMING and RETURNING the axis.

Tool Change

Sends the TOOL CHANGE command to the CNC.

Toolbar Button

Color Indicator

Description

Action

Alarm

Gray

Normal state

None

Flashing yellow

Fault

Follow fault action screen

Current Fault

Indicators

Flashing Fault

Indicator

Close

Button

General Status

Indicators

Alarm Indicator