Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 122

122

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Chapter 4

GuardLogix Configuration

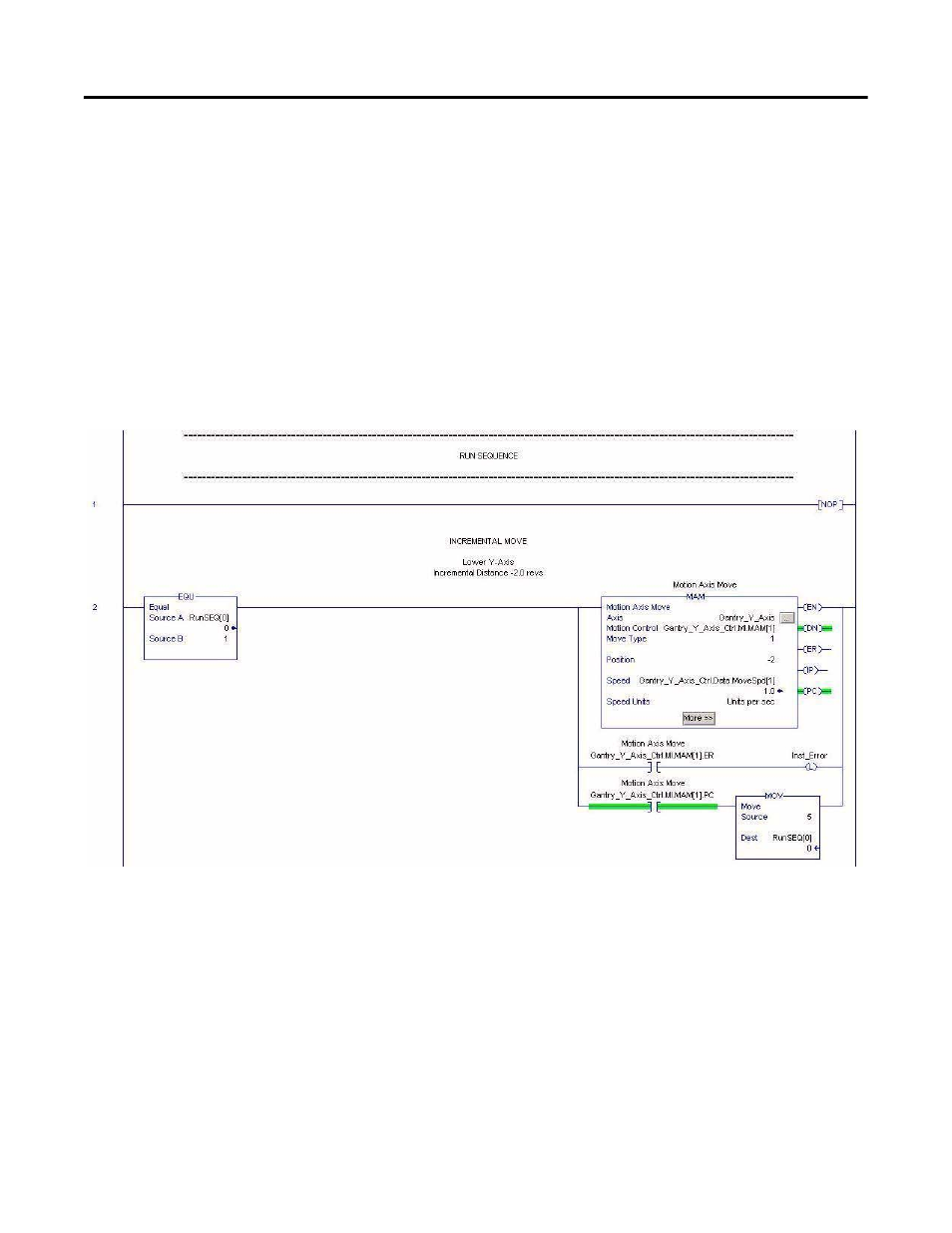

The run sequence is initiated by a machine START command via the start logic in the R03_Control routine of

the application module. By default, the run sequence is initiated by placing a value of 1 in the RunSEQ[0] tag.

When the RunSEQ[0] tag is set to 1, the first step in the run sequence is executed, starting the run sequence.

Each of the rungs in the run sequence provides a placeholder where you can insert application-specific step logic.

The Run-sequence logic may include, for example, CNC commands, and/or other conditional diagnostic logic.

The move (MOV) instruction is a placeholder to advance the run sequence to the next step by incrementing the

RunSEQ[0] tag. Each step in the run sequence requires a unique value assigned in ascending order. The steps

typically increase by multiples of five or ten. By default, the run-sequence template steps 1…10…20…30, and so

on. Before moving to the next step, a predetermined condition must normally be met to make sure the current

step is complete.

Figure 10 - First Run Sequential Step Example

This CNC Work Cell application code first-run step (RunSEQ[0] = 1) example includes a latch (L) instruction,

as well as a MOV instruction for assigning a simulation number, used for this example. Also, the RunSeq MOV

instruction indexes to the next sequence step (for example, value 3 into RunSEQ[0] tag). The next rung, that has

EQU RunSeq = 3 as its condition, is then executed, and so forth.