Guardlogix safety logic – Rockwell Automation IASIMP Computer Numerical Control (CNC) Machining Accelerator Toolkit Quick Start User Manual

Page 138

138

Rockwell Automation Publication IASIMP-QS034A-EN-P - October 2012

Chapter 4

GuardLogix Configuration

GuardLogix Safety Logic

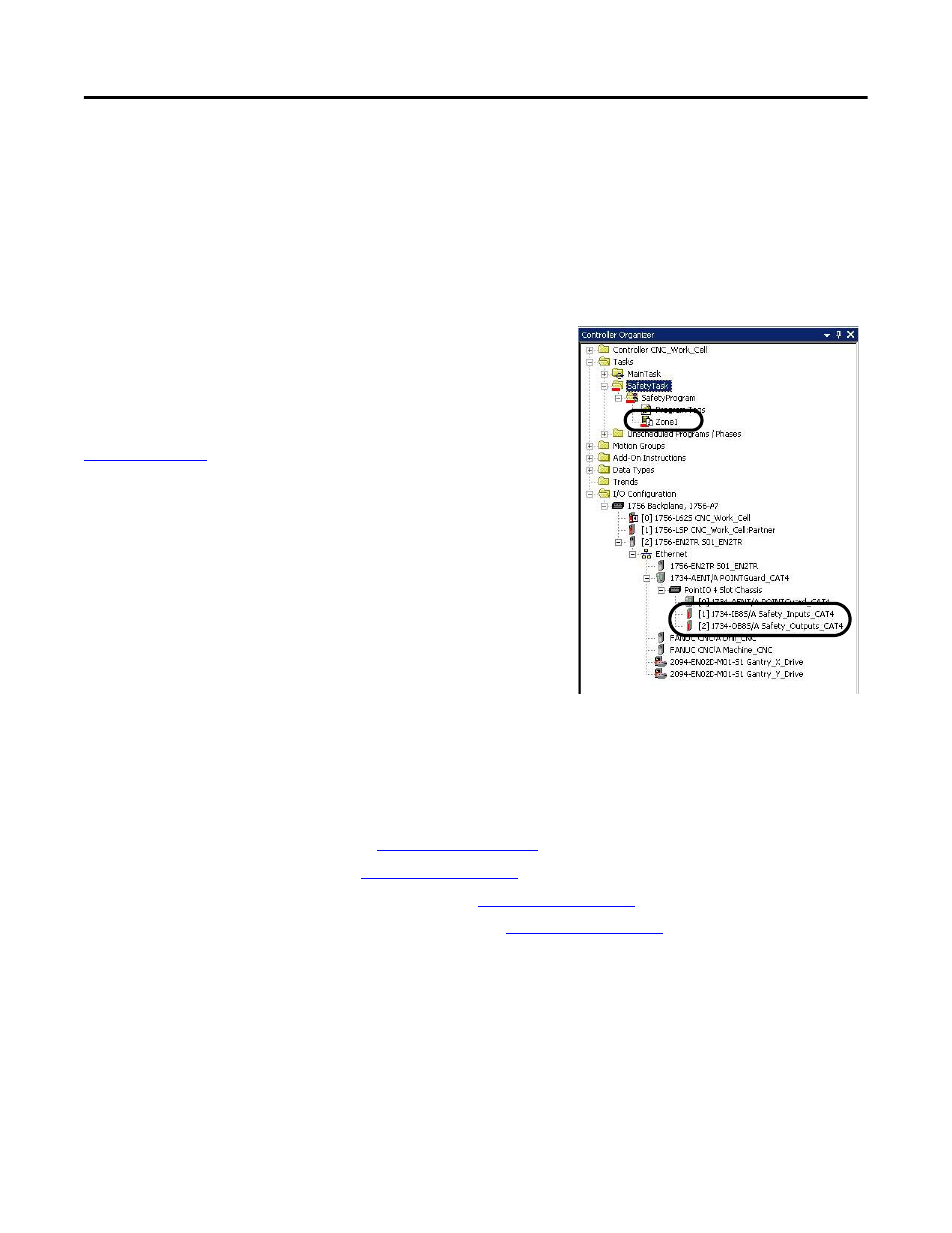

The toolkit also provides example GuardLogix safety logic and associated FactoryTalk View ME safety

faceplates. The example GuardLogix safety configuration and logic is in the

CNC_Work_Cell_Logic_w_Safety.ACD file.

The file path is C:\Program Files\RA_Simplification\CMAT\A-Files\6-Project Examples\CNC-Work-Cell\.

For this example, one SafetyPoint input module and one

SafetyPoint output module is configured. The safety logic is located

in the Zone1 safety routine within the Safety Task.

The safety input and output logic is based on the example code

provided in the Safety Accelerator Toolkit DVD, publication

ou may use this toolkit to streamline your safety

wiring, logic, and HMI interface for your specific GuardLogix

project.

The Zone1 routine includes safety input logic for an EStop push button, light curtain, and Dual Check Safety

interlocks from the FANUC Drill and Machine CNC systems. The dual channel input stop instructions are

used for all of the inputs, but are configured a bit differently. See the rung comments for configuration

information for these examples:

•

Zone 1 Emergency Stop Example –

•

Zone 1 Light Curtain Example –

•

Zone 1 Dual Check Safety Drill CNC Example –

•