Chapter 10 appendix – IAI America SCON-CA User Manual

Page 292

Chapter 10

Appendix

282

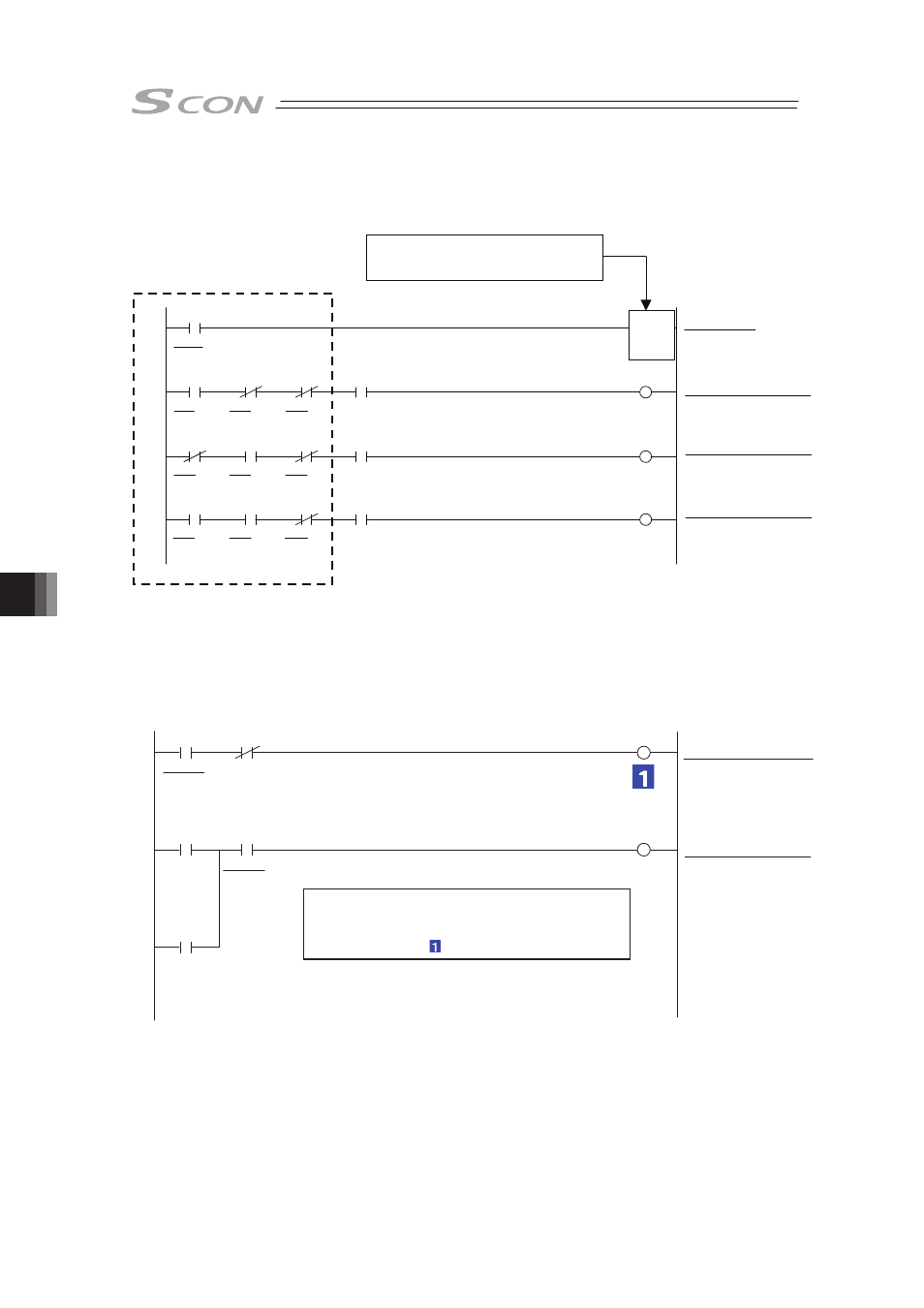

[6] Decode Circuit of Positioning Complete Position No.

The decode circuit converts the binary data of positioning complete position No. sent from

SCON to PLC into the corresponding bit data.

054

056

061

066

PEND

Point Positioning

Completion

Point Positioning

Completion

PM1

Completed

Position

No1.

PM2

Completed

Position

No2.

PM4

Completed

Position

No.

IN13

IN5

IN6

IN7

Point Positioning

Completion

PM1

Completed

Position

No.1

PM2

Completed

Position

No.2

PM4

Completed

Position

No.

IN5

IN6

IN7

Point Positioning

Completion

PM1

Completed

Position

No.1

PM2

Completed

Position

No.2

PM4

Completed

Position

No.

IN5

IN6

IN7

AUX4

AUX5

AUX6

Point Positioning

Completion

Completed Position No.1

Completed Position No.2

a059 a064 a069

a094 a100

a 1 12 a 1 18

Completed Position No.3

a081 a130

TIM4

TIM4

TIM4

200ms

is set

to TIM4

This is the timer to prevent the code reading

error since the scanning is held independently

by PLC and RC controller.

[7] Actuator Start Circuit

If the “Operation” switch on the operation box is pushed, the lamp of the “Operation”

pushbutton switch described in 11.3.3 Operation and Stop Circuit goes on and, at the same

time, the actuator starts successive positioning of position No. 1�2�3�1�2•••. The circuit

below is intended for the activation.

Because the operation signal remains ON until the

stop button is pushed, pulsed start signal is generated

so that the circuit for moving to the first position (No.1)

may not remain ON. operates next circuit.

S T A R T L

AUX8

RC Start

Display

Aux. Position 1

Positioning Start Pulse

AUX7

Position 1

Positioning

Start Pulse

071

071

OUT1

OUT1

AUX7

AUX8

a074 a078

S T A R T L

RC Start

Display

Aux. Position 1

Positioning Start Pulse

a072 a075

Aux. Position 1

Positioning Start Pulse

AUX8

Aux. Position 1

Positioning Start Pulse