IAI America SCON-CA User Manual

Page 249

Chapter 9

Troubleshooting

239

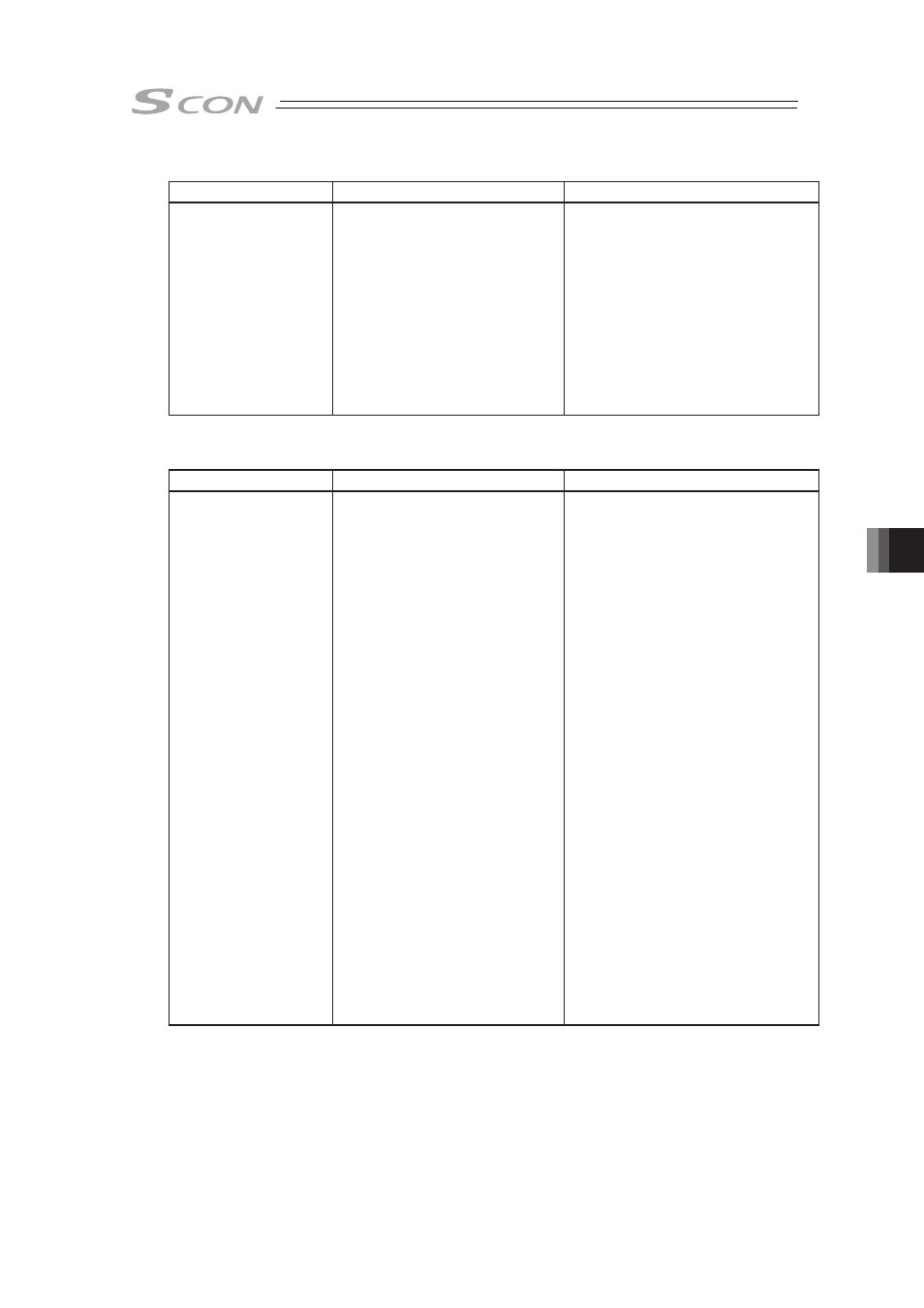

[In the case of Positioner Mode]

Situation

Possible cause

Check/Treatment

Both position No. and

start signal are input to

the controller, but the

actuator does not move.

There is a problem either in PIO

signal treatment, position table

setting or operation mode selection.

1) Servo OFF condition

2) The pause signal is OFF.

3) Positioning command is issued

to a stop position.

4) There is no positioning data set

to the commanded position

number.

1) Is the status display LED SV turned

ON? [Refer to Name for Each Parts

and Their Functions]

Turn ON the servo-on signal SON of

PIO.

2) Operation is available when PIO

pause signal *STP is ON and pause

when it is OFF. Turn it ON.

3) Check the sequence or the settings

of the position table.

4) It will generate Alarm Code 0A2

“Position Data Error”. Conduct the

position table setting.

(Note) Refer to 2.1.3 [5] PIO Circuit for PIO signal.

[In the case of Pulse String Control Mode]

Situation

Possible cause

Check/Treatment

In spite of inputting

pulse-train to the

controller, the actuator

does not move.

PIO signal processing or parameter

setting is incorrect.

1) Servo OFF state

2) The pause signal is OFF.

3) The pulse-train type, a

parameter, is selected

incorrectly.

4) The positive/negative logic of

pulse-train, a parameter, is

selected inversely.

5) The unit moving distance per

pulse, which is a setting

condition of electronic gear ratio,

a parameter, is too small.

1) Is the status display LED SV turned

ON? [Refer to Name for Each Parts

and Their Functions]

Turn ON the servo-on signal SON of

PIO.

2) Operation is available when PIO

pause signal *STP is ON and pause

when it is OFF. Turn it ON.

3) Check the pulse train type.

[Refer to 3.3.4 [2] Format Settings of

Command Pulse Train.]

4) Check the positive/negative logic of

pulse-train. (Host units supplied by

some manufacturers have

positive/negative logic opposite to

our logic. Reserve the logic setting

and try the operation.)

[Refer to 3.3.4 [2] Format Settings of

Command Pulse Train.]

5) Do not make the unit moving

distance less than the resolution of

the encoder. The actuator does not

move unless pulses by the

resolution of the encoder are input.

[Refer to Caution in 3.3.4 [1]

Electrical Gear Setting]

(Note) In case of 3) or 4), the

actuator may not sometimes

operate smoothly.

You may not find case 5)

when the actuator is moved

for a long distance at a high

frequency.

(Note) Refer to 2.2.3 [5] PIO Circuit for PIO signal.