IAI America SCON-CA User Manual

Page 260

Chapter 9

Troubleshooting

250

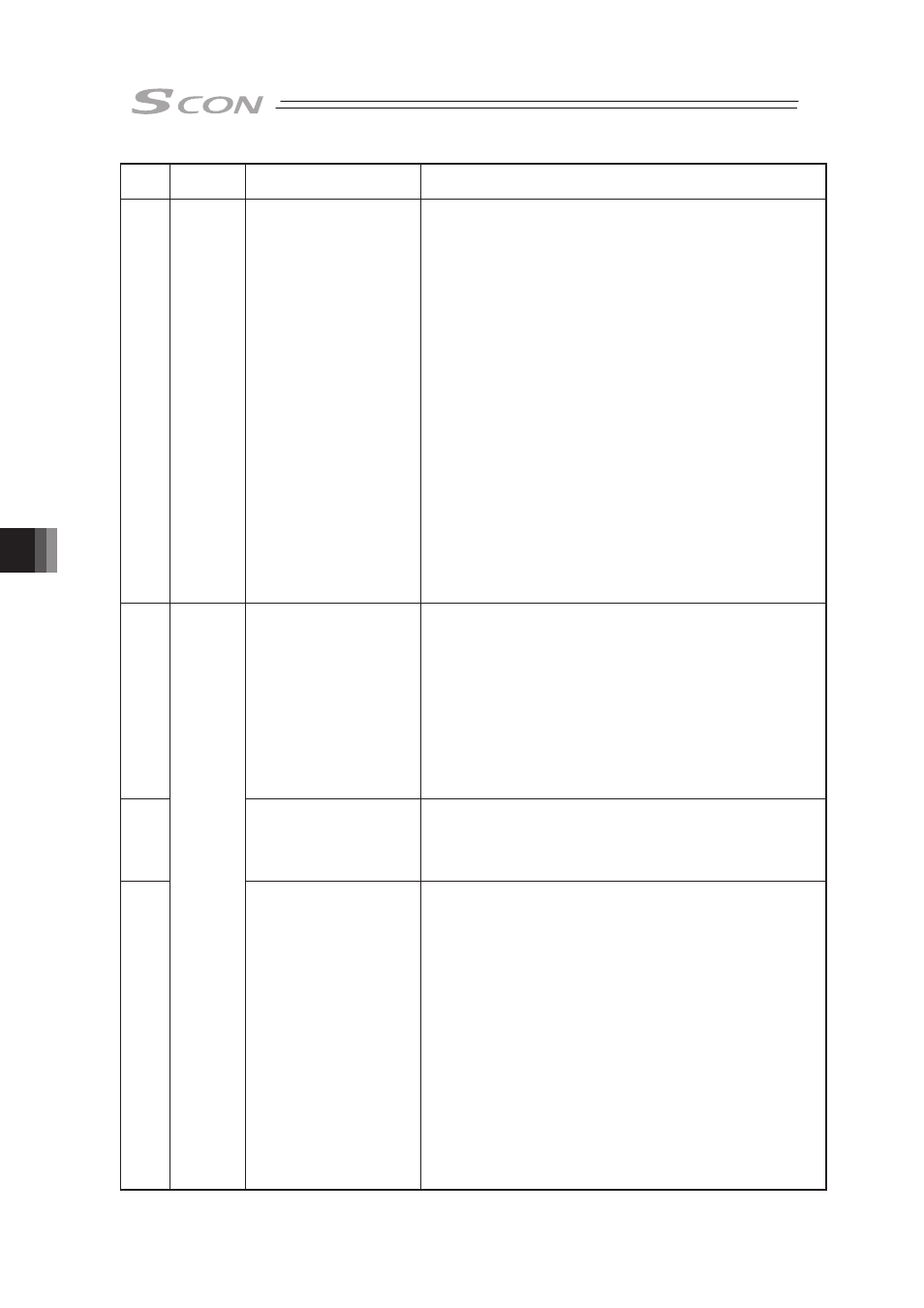

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0B7

Cold start

Magnetic pole

indeterminacy

Cause

: The controller detects the magnetic pole phase

when the servo is tuned ON for the first time after

turning ON the power. This error indicates that the

magnetic pole phase cannot be detected after the

specified period.

1) Contact error or breakage at the connector of the

motor relay cable.

2) Brake cannot be released on a controller

equipped with a brake.

3) Detection of the motor is not performed properly

because an external force is applied.

4) Large slide resistance of the actuator itself

Treatment : 1) Check the wiring condition of the motor relay

cable.

2) Check the wiring condition of the brake cable,

and also turn on/off the brake release switch to

see if the brake makes a “clicking” sound. If the

brake is not making any noise, check if the

power is supplied to the brake properly.

3) Check for abnormality in the assembly condition.

4) It the transportation weight is in the acceptable

range, cut off the power to check the slide

resistance manually by moving with hand.

If the actuator itself is suspected to be the cause,

please contact IAI.

0BA

Home sensor

non-detection

Cause

: This indicates that the home-return operation of the

actuator equipped with origin sensor (option except

rotary actuator) is not completed in normal

condition.

1) Work is interfering with peripheral equipment in

the middle of home return.

2) Large slide resistance of the actuator itself

3) Installation failure, breakdown or disconnection

of the home sensor

Treatment : In the case that the work does not interfere with

anything, the cause 2) or 3) is supposed. In such

case, please contact IAI.

0BE

Home return timeout

Cause

: Home return does not complete after elapse of a

certain period after the start of home return.

Treatment : This error does not occur in normal operation. The

combination of the controller and actuator may be

incorrect. Please contact IAI.

0BF

Operation

release

Creep sensor not detected Cause

: This indicates the actuator detected the creep

sensor (option) before detecting the origin sensor

(option except for rotary actuator), or the actuator

reached the mechanical end (or the actuator cannot

move anymore because the load is too large).

1) The position to apply the creep sensor is not

appropriate.

2) The creep sensor is faulty.

3) The cable is disconnected or the connector is

not plugged in properly.

4) The actuator cannot move due to heavy load

caused by interference.

Treatment : 1) Readjust the sensor installation position.

2) Replace the creep sensor.

3) Perform continuity check to see if the connector

is plugged in properly.

4) Check the interference and the transportable

weight and make sure there is no external force

applied.