IAI America SCON-CA User Manual

Page 266

Chapter 9

Troubleshooting

256

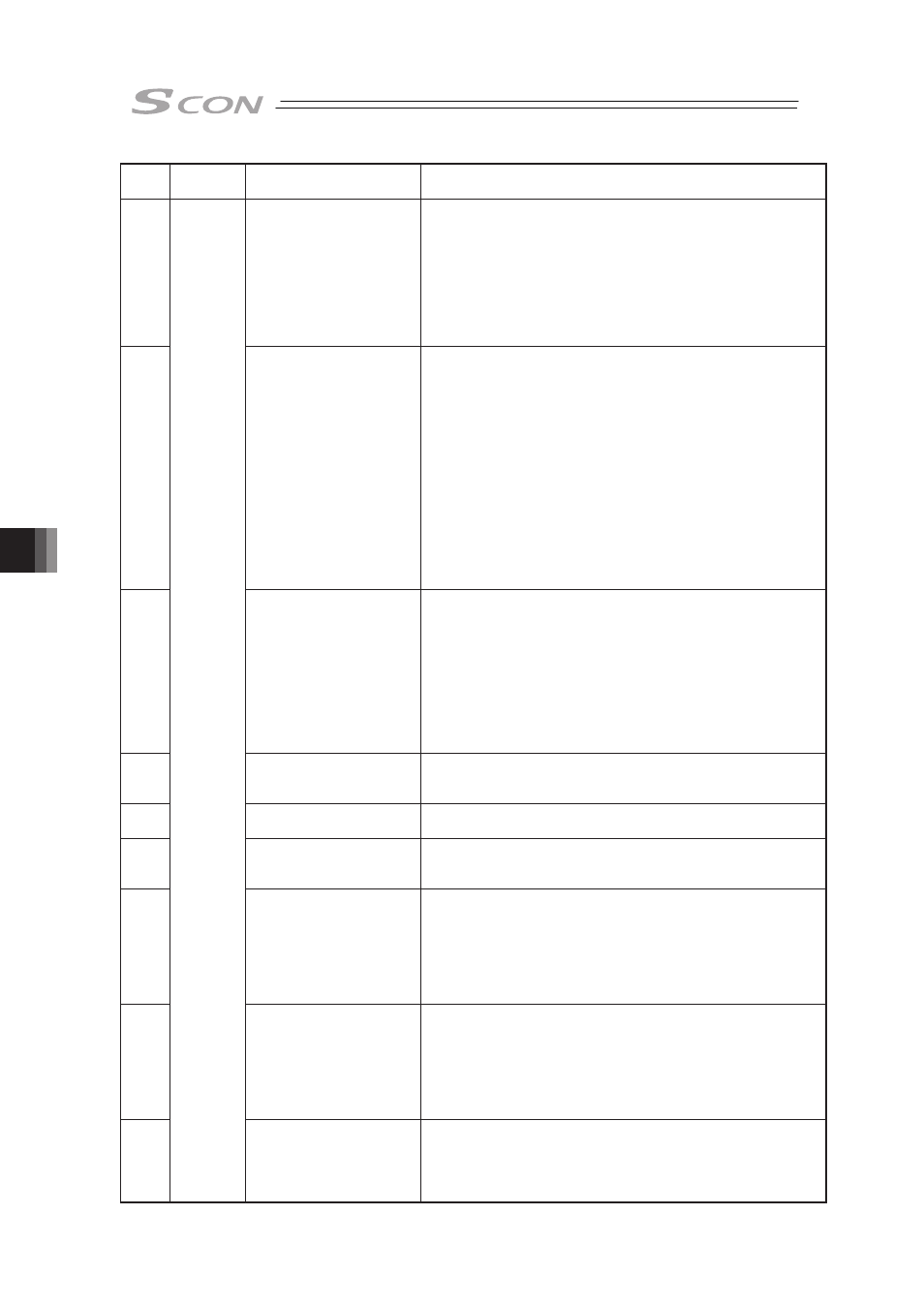

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0E7

A-, B- and Z-phase wire

breaking

Cause

: Encoder signals cannot be detected correctly.

1) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

2) The encoder itself is faulty.

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

If the cables are normal, faulty encoder is

suspected. Please contact IAI.

0EE

Absolute encoder error

detection 2

Cause

: This is the condition where the position information

can not be detected in the absolute encoder.

1) Voltage drop of absolute battery.

2) The encoder relay cable or supplied actuator

cable is disconnected or its connector is not

plugged in correctly.

Treatment : 1) Check the PIO battery alarm output (*BALM) and

when it is turned OFF, replace the absolute

battery with new one.

2) Check if any wire breakage on a connector and

the condition of wire connections.

Whichever action is taken under 1) or 2), an

absolute reset must be performed.

If the cables are normal, faulty encoder is

suspected. Please contact IAI.

0EF

Absolute encoder error

detection 3

Absolute encoder is not detecting the position information

properly. (ABS encoder overspeed error)

Cause

: This error occurs in such cases as the speed

exceeded the tracing acceleration speed limit in the

drop by the brake release at the power cutoff of the

absolute type vertical axis. (This condition should

not occur in normal conditions of use. Take

sufficient note on forced brake release.)

Treatment : If the error is occurred, it is necessary to absolute

reset.

0F0

Driver logic error

Cause

: Exceeded load, parameter (motor type)

mismatched, noise, malfunction of controller, etc.

Treatment : Please contact IAI.

0F2

Field bus module error

Cause

: A Field bus Module error was detected.

Treatment : Check the Field bus related parameters.

0F3

Field bus module not

detected

Cause

: Field bus module not detected.

Treatment : If the error cannot be resolved even after putting the

power on again, please contact us.

0F4

Mismatched PCB

This controller uses a different print circuit board depending on

the motor capacity.

The PCB is not applicable for the connected motor in the startup

check.

Cause

: The actuator may not match the controller. Check

the model.

Treatment : Should this error occur, please contact IAI.

0F5

Nonvolatile memory write

verify error

It is verified at the data writing process to the non-volatile

memory that the data inside the memory and the data to be

written are matched. There was a mismatch detected in this

process.

Cause

: Faulty nonvolatile memory.

Treatment : When the error is caused even when the power is

re-input, please contact IAI.

0F6

Cold start

Nonvolatile memory write

timeout

There is no response in the specified time duration during the

data writing to the non-volatile memory.

Cause

: Faulty nonvolatile memory.

Treatment : When the error is caused even when the power is

re-input, please contact IAI.