4] pressing operation, Chapter 3 operation, Sample use – IAI America SCON-CA User Manual

Page 120

Chapter 3 Operation

110

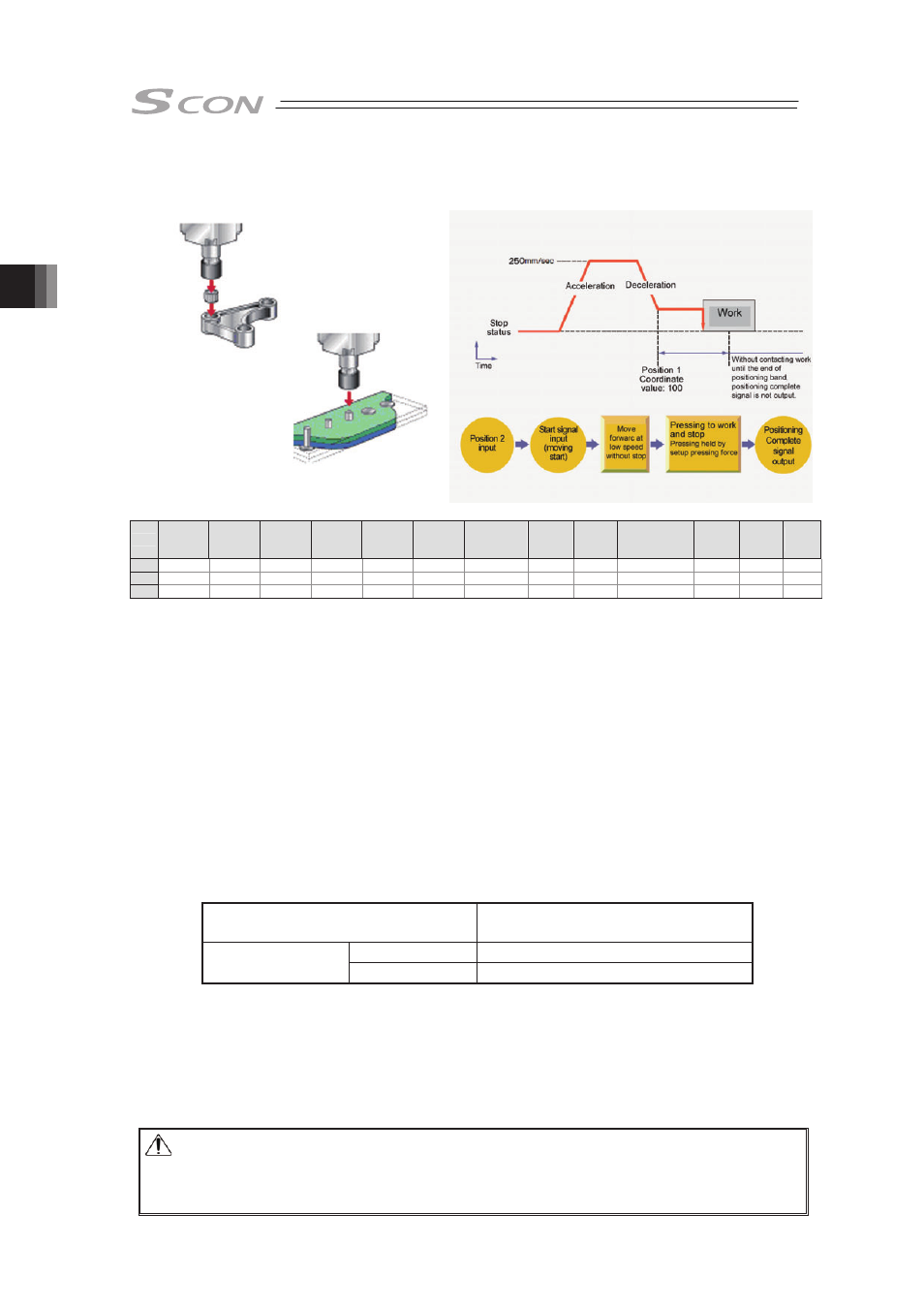

[4] Pressing operation

�

Sample use

Velocity

1)

2)

3)

4)

5)

1) 2)

3)

4) 5)

Positioning width 50

Press-fitting process

Caulking process

No.

Position

[mm]

Velocity

[mm/s]

Accele-

ration

[G]

Decele-

ration

[G]

Pressing

[%]

Thresh-

old

[%]

Positioning

width

[mm]

Zone+

[mm]

Zone-

[mm]

Acceleration/

Deceleration

mode

Incre-

mental

Gain

set

Stop

mode

0

1

0.00

250.00

0.20

0.20

0

0

0.10

0.00

0.00

0

0

0

0

2

100.00

250.00

0.20

0.20

50

0

50.00

0.00

0.00

0

0

0

0

(Position No.2 sets pressing operation.)

�

Control method

1) The method of controlling the pressing operation is the same as that described in [1]

Positioning except the setting of the position table. Any setting of “Pressing” in the position

table allows the pressing operation to be done. “Positioning width” is assumed as pressing

operation distance.

2) The actuator moves at the setting speed and rating torque to the position of the coordinate

set in “Position” in the similar way as normal positioning. Then the operation changes to

pressing. The moving distance in pressing is the value set in “Positioning width”. The

pressing is performed with the torque (current limit value) set in percent in “Pressing” of

PIO patterns 0 to 3 being the upper limit.

Pressing operation using force sensor of PIO pattern 6 performs pressing by the pressing

force set in percent of the base thrust in pressing operation using force sensor*.

* Base thrust in pressing operation using force sensor:

Converted thrust at rating motor output in pressing operation using force sensor

Actuator

Base thrust in pressing operation using

force sensor [N]

1t type

4900

RSC2-RA13R

2t type

9800

3) The control method is the same as that in [1] Positioning. However, the processing of

positioning complete signal PEND is different from that in [1] Positioning.

PEND is output when the shaft is stopped by pressing (pressing complete). If the work is

not subject to pressing (miss-pressing), the actuator moves by the value set in “Positioning

width” to stop but PEND is not turned ON. Completed Position No. PM1 to PM** turn on

both when the pressing operation is complete and when miss-pressing.

Caution: When having a pressing operation using force sensor, it is necessary to calibrate

the loadcell.

[Refer to 3.2.7 Pressing Operation Using Force Sensor Operation Ready

(Calibration of Loadcell)]