IAI America SCON-CA User Manual

Page 261

Chapter 9

Troubleshooting

251

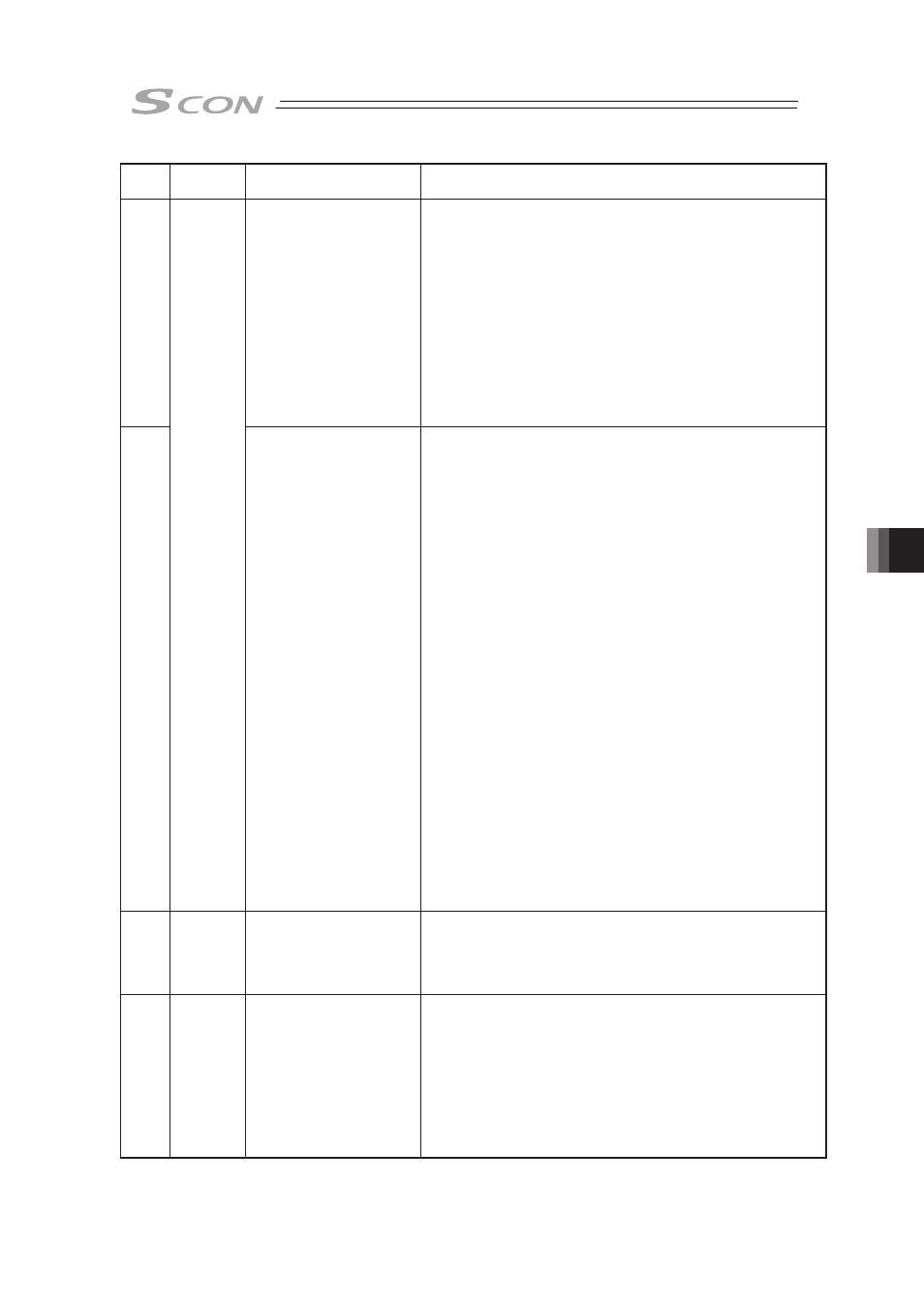

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0C0

Actual speed excessive

Cause

: This indicates the number of motor rotation

exceeded the number of allowable rotation.

1) The slide resistance of the actuator is locally

high.

2) The load is increased too much due to a external

force.

With the reasons above, it can be considered a

sudden speed increase has occurred before

detecting the servo error.

Treatment : Even though this would not occur in normal

operation, check if there is any abnormality in the

parts assembly condition. Also check if there is a

possibility that an external force may be applied in

the direction of the actuator movement.

0C2

Operation

release

Overrun sensor detected Cause

: This indicates that a signal from the OT sensor

(option) installed at the mechanical end is detected.

1) The actuator was moved by hand or received

external force while the servo was OFF (normal

detection).

2) The actuator was jogged or operated by

pulse-train in a condition where the home

coordinates were not yet established and thus

the soft stroke limit did not function correctly

(normal detection).

3) The home position achieved by home return is

not correct, or in the case of an absolute type

controller the coordinates have shifted due to an

inappropriate absolute reset position.

4) There is a mismatch between the sensor

characteristics and the setting in Parameter

No.19 “Overrun sensor input polarity”, or the

wiring layout is wrong.

5) There is a mistake in the mating of the controller

and actuator, or the settings in Parameters No.3

and 4 “Soft limit value” and Parameter No.77

“Ball screw limit length” are not appropriate.

Treatment : If 1) or 2) is suspected, move the actuator in the

opposite direction by hand.

If this error occurred inside the effective stroke

range, 3), 4), or 5) is a likely cause.

If 3) is suspected, check the home position.

Conduct the absolute reset again if it is the absolute

type.

If 4) or 5) is suspected, please contact IAI.

0C4

Cold start

Exceeded allowable time

of exceeding torque

allowing continuous

pressing

Cause

: The continuous pressing time exceeds the time set

for parameter No.89 “Allowable time of exceeding

torque allowing continuous pressing”.

Treatment : Check the sequence again.

Set the pressing time to be within the setting time.

0C5

Operation

release

Illegal transition command

in control system

Cause

: 1) Change the operation from the vibration

suppress control operation to the normal position

control operation.

2) Change the operation from the normal position

control operation to the vibration suppress

control operation.

Treatment : Change the sequence so the next action is

conducted after confirming the positioning complete

signal (PEND) is turned ON for both cases 1) and

2).