IAI America SCON-CA User Manual

Page 127

Chapter 3 Operation

117

4) In the similar way as pressing, the positioning complete signal is output when the shaft is

stopped by tension (pressing complete). If the actuator cannot be stopped during

movement within the setting positioning width (miss-pressing), it moves by the setting

distance to stop but PEND is not turned ON. Completed Position No. PM1 to PM** turn on

both when the tension operation is complete and when miss-pressing.

Caution: (1) The speed during tension operation is set in Parameter No.34. Check the

10.4 List of Specifications of Connectable Actuators for the pressing

operation speed. The speed for tension operation is same as that for

pressing operation.

Do not set any value larger than the value in the list. If the speed set in the

position table is equal to or less than the tension speed, the tension

operation is performed at the setup speed.

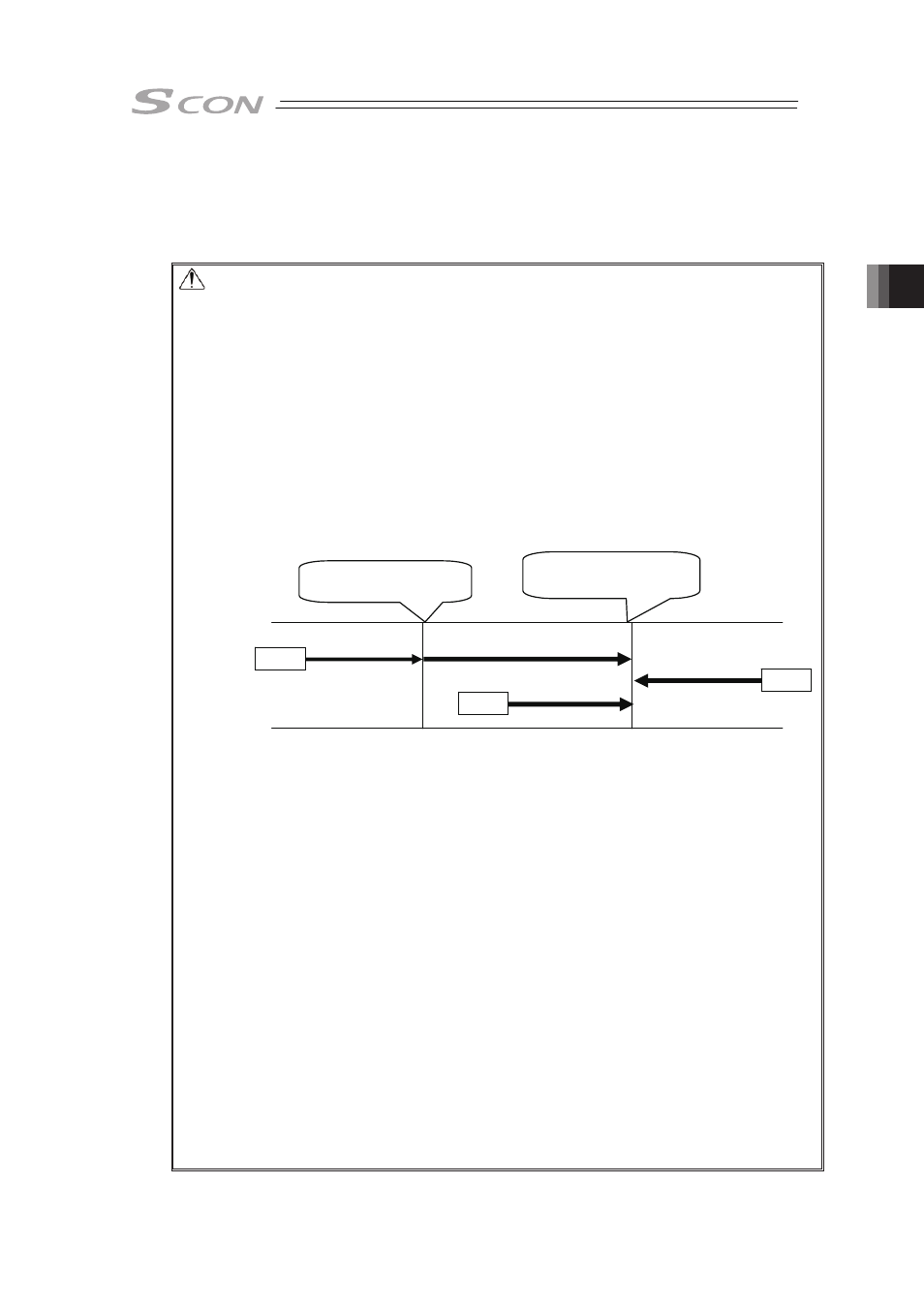

(2) The tension ready position should be the tension start position or forward. If

not, the moving direction varies depending on the start position to be

dangerous.

The tension operation from a coordinate (less than 30mm = 80 – 50 in the

above example) located before the end position (30mm) changes to the

pressing operation from the current position to the tension end position.

Please note that it cannot be the tension operation to the point of 30mm

after the positioning at the point of 80mm.

(3) The work is pulled also after completion of the tension. The work is drawn

back or pulled further if the work is moved. When the work is drawn back

before the approach position, alarm code 0DC “Pressing Motion Range

Over Error” occurs to stop the work. When the work is moved in the tension

direction and the load current becomes less than the current limit value

(pressing in percent), PEND is turned OFF. Miss-pressing occurs when the

actuator moves by the pressing moving distance set in “Positioning width”.

Completed Position No. PM1 to PM** keep turned on until the next

movement command is made even if the work piece gets moved and

pulled backward or further forward once they are turned on at the tension

operation complete.

(4) Do not make control of changing to tension operation on the way of normal

positioning (before PEND turning ON). Depending on the position at which

start signal is turned ON, the tension operation is performed improperly.

Then the PLC cannot manage the position of the actuator.

(5) Tension operation cannot be performed with the rotary actuator.

(6) If the actuator is RCS2-RA13R (Ultra-High Thrust Type), there is a limit in

the continuous tension time (= continuous pressing time) and the duty of

continuous pressing. Use of the product above this limit may cause a

failure occurred due to the motor heat generation.

[Refer to 10.4.2 Specifications and Limitations in Pressing Operation of

RCS2-RA13R]

Pressing operation

CSTR: Start position

CSTR

CSTR

CSTR

Tension operation

Approach operation

Tension operation

Tension start position

80mm

Tension end position

80 – 50 = 30mm