According to sequence program creation – IAI America SCON-CA User Manual

Page 20

10

10. Limitations on operation of rotary actuator in index mode

Rotary actuators of 360-degree specification can select the normal mode for finite rotations or

the index mode enabling multi-rotation control by using parameter No.79 “Rotational axis mode

selection”. [Refer to Chapter 8 I/O Parameter.]�

The following limitations are applied to the index mode:

1) Controllers of absolute specification cannot select the index mode. If selected, alarm code

0A1 “parameter data error” is issued.

2) Index Mode cannot be selected in Pulse Train Control Mode. It will generate Alarm Code

0A1 “Parameter Error”.

3) The command range in the jog operation with PC software, teaching pendant or PIO signal

is 0 to 360.00�.

4) Pressing is unavailable. The pressing torque can only be set to 0.

5) Do not issue positioning command around 0� repeatedly during movement near 0�. Failure

to follow this may cause the actuator to rotate in the direction reverse to the specified

rotation direction or operate indefinitely.

6) Software stroke limit is invalid in the index mode.

�

11. According to Sequence Program Creation

Please note the following things when creating a sequence program.

When data transfer is necessary between two devices that have a different scan time from each

other, duration more than the longer scan time is required to certainly read the signal. (It is

recommended to have at least twice of the longer scan time for the timer setting to conduct the

reading process on the PLC side safely.)

�

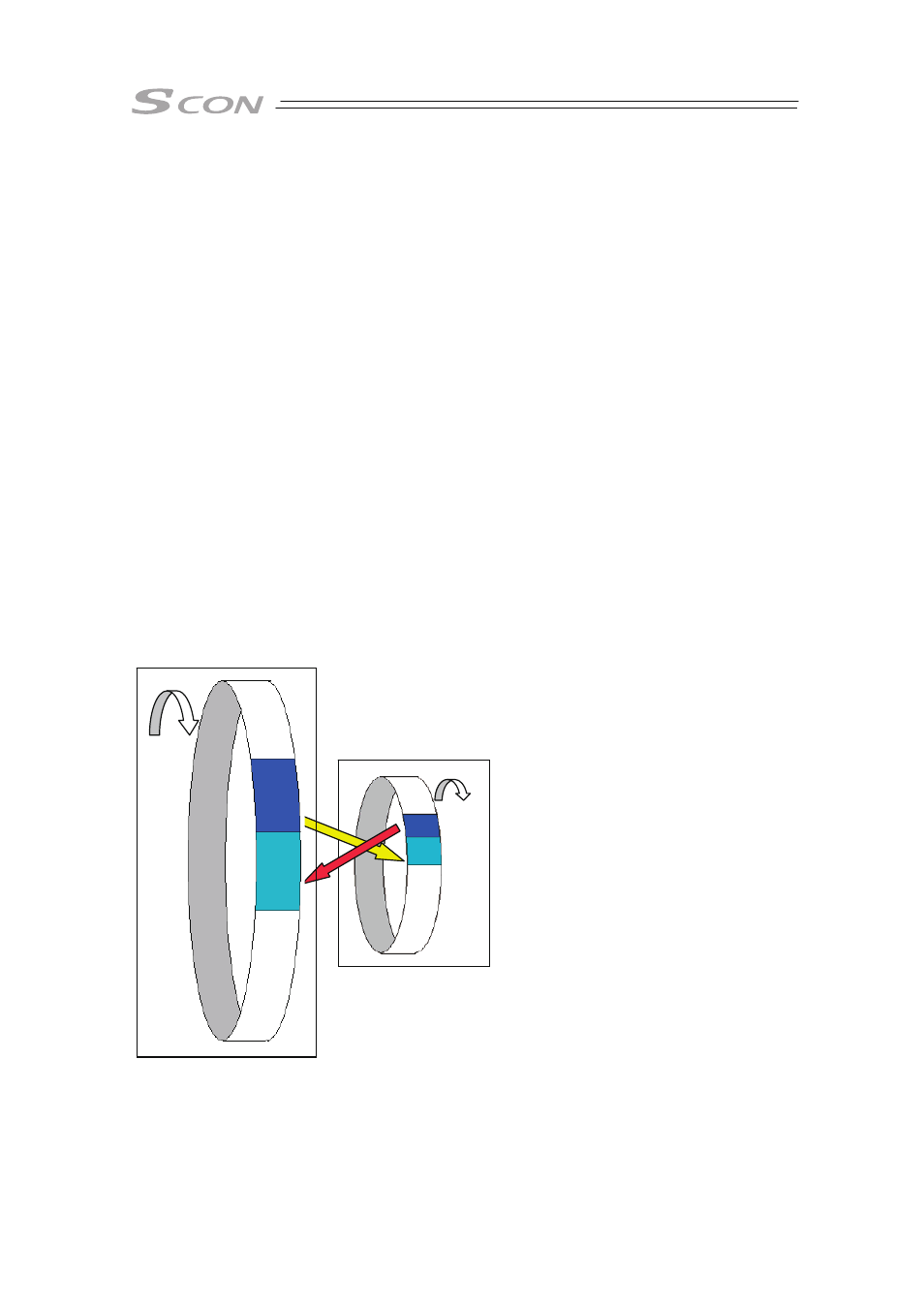

� Operation Image

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

Also, if one tries to read the signal that is being re-written by the other, the signal may be read wrongly.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more than 2 scan

periods to wait.) Make sure not to have the output side to change the output until the other side completes

the reading. Also, a setting is made on the input area not to receive the signal less than a certain time to

prevent a wrong reading of noise. This duration also needs to be considered.�

This controller

(scan time 1msec)

PLC

(e.g. scan time is 20msec)

As shown in the diagram, the input and output

timings of two devices that have different scan

time do not match, of course, when transferring

a signal.

There is no guarantee that PLC would read the

signal as soon as this controller signal turns on.

In such a case, make the setting to read the

signal after a certain time that is longer than the

longer scan time to ensure the reading process

to succeed on the PLC side.

It is the same in the case this controller side

reads the signal.

In such a case, it is recommended to ensure 2

to 4 times of the scan time for the timer setting

margin.

It is risky to have the setting below the scan

time since the timer is also processed in the

scan process.

In the diagram, PLC can only read the input

once in 20msec even though this controller

output once in 1msec.

Because PLC only conducts output process

once in 20msec, this controller identifies the

same output status for that while.

Output

Process

Input

Process