IAI America SCON-CA User Manual

Page 258

Chapter 9

Troubleshooting

248

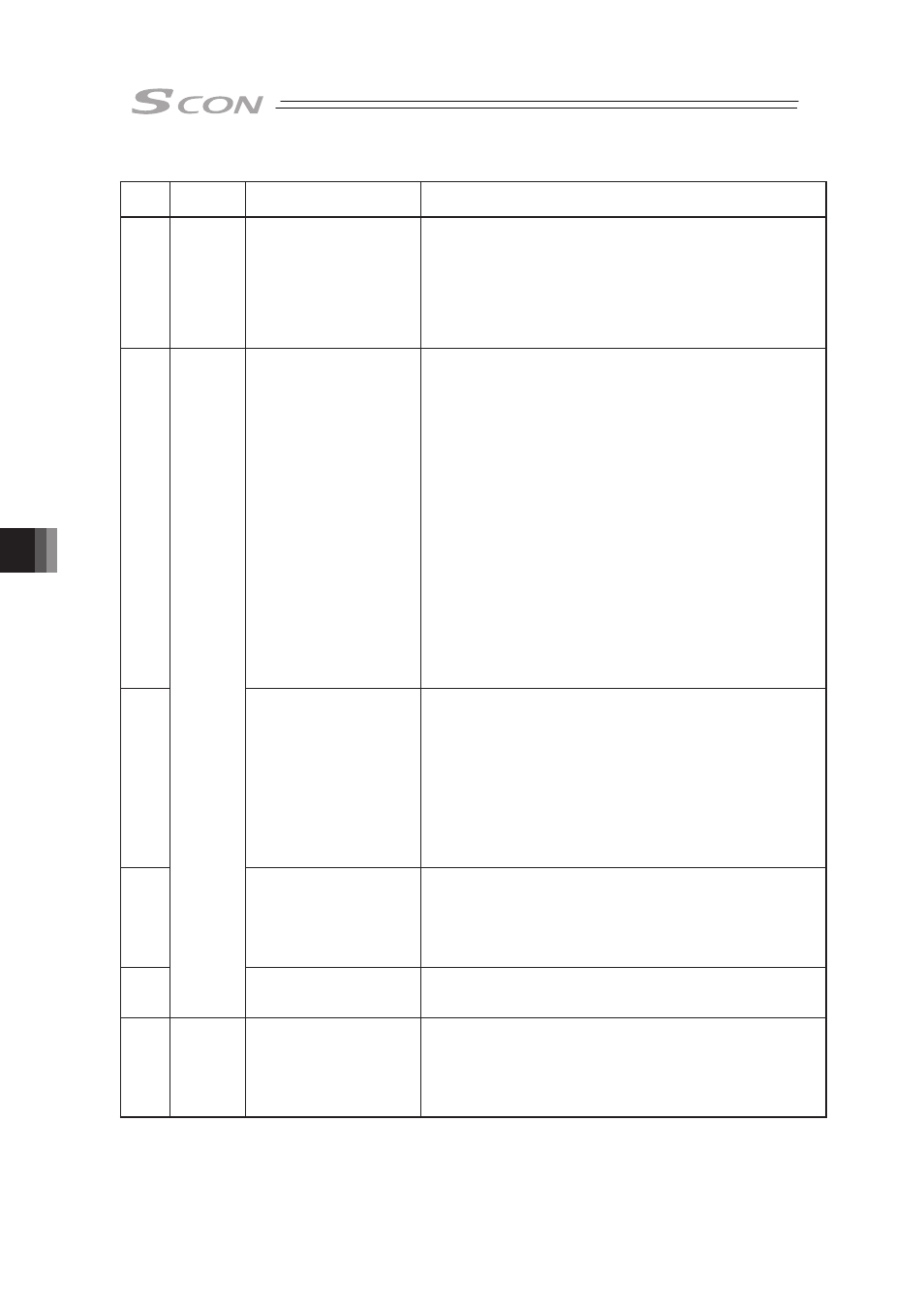

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0A1

Cold start

Parameter data error

Cause

: The data input range in the parameter area is not

appropriate.

This error occurs when the magnitude relationship

is apparently inappropriate such as when 300mm

was incorrectly input as the value of the soft limit

negative side while the value of the soft limit

positive side was 200.3mm.

Treatment : Change the value to the appropriate one.

0A2

Position data error

Cause

: 1) A move command was input when no target

position was set in the “Position” field of a

position No. in the position table.

2) The value of the target value in the “Position”

field exceeded the Parameter No.3 and 4 “Soft

limit set value”.

3) A target position was specified in the “Position”

field by relative coordinate in the solenoid valve

mode 2 of PIO pattern 5.

4) Pressing operation was specified while the

vibration suppress control function remained

effective.

Treatment : 1) Set the target position.

2) Change the target position value to the one

within the soft limit set value.

3) The target position cannot be set by relative

coordinate (incremental feed).

4) The vibration suppress control function and

pressing operation cannot be used concurrently.

Provide setting so that either of the functions is

effective.

0A3

Position command data

error

Cause

: 1) The speed or acceleration/deceleration value

during direct numeric specification exceeded the

maximum set value.

2) Pressing operation was specified in the field bus

specification while the vibration suppress

function remained effective.

Treatment : 1) Table to input a proper value.

2) The vibration suppress control function and

pressing operation cannot be used concurrently.

Provide setting so that either of the functions is

effective.

0A4

Command counter

overflow

Cause

: The number of input command pulses exceeded

the range of -134217728 to +134217728

(H'F8000000 to '07FFFFFF).

Treatment : Attempt to make the value of the electrical gear

ratio smaller (make the movement against the unit

bigger).

0A5

Operation

release

Electromagnetic brake

unreleased error

Cause

: The brake cannot be released.

Treatment : Supplied the 24V power unit for the electromagnetic

brake.

0A6

Cold start

Dynamic brake not

released

Cause

: The dynamic brake cannot be released when the

servo is ON due to noise and electrostatic, etc.

Treatment : Implement measures to eliminate noise or

electrostatic.

There is a concern of circuit breakdown. Please

contact IAI.