11 sensorless operation (without an encoder) – Efficient Networks Siemens Sinamics S120 User Manual

Page 88

Servo control

3.11 Sensorless operation (without an encoder)

Drive Functions

88

Function Manual, (FH1), 07/2007 Edition, 6SL3097-2AB00-0BP4

Example of measuring the speed controller frequency response

By measuring the speed controller frequency response and the control system, critical

resonance frequencies can, if necessary, be determined at the stability limit of the speed

control loop and dampened using one or more current setpoint filters. This normally enables

the proportional gain to be increased (e.g. Kp_n = 3* default value).

After the Kp_n value has been set, the ideal integral action time Tn_n (e.g. reduced from

10 ms to 5 ms) can be determined.

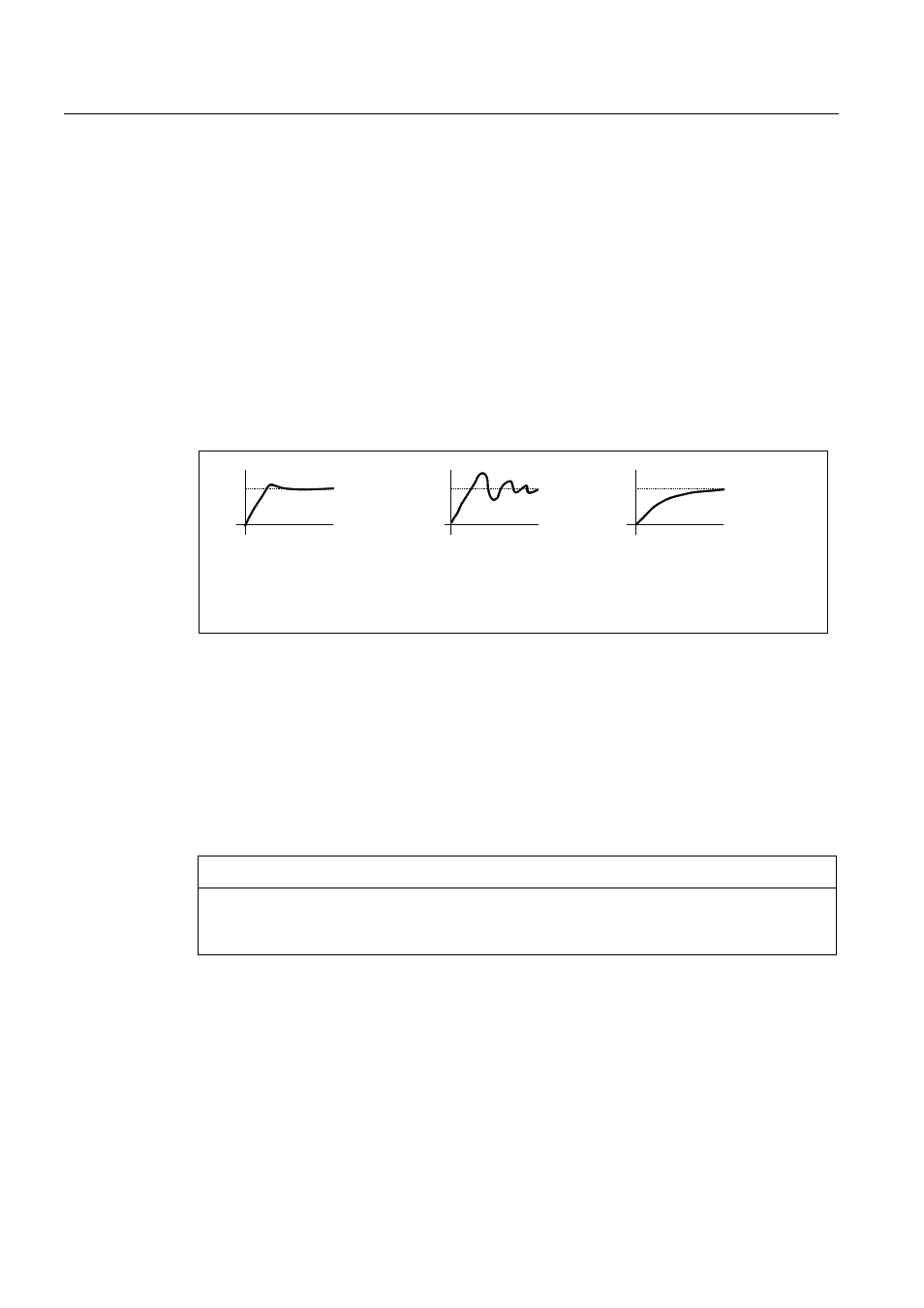

Example of speed setpoint step change

A rectangular step change can be applied to the speed setpoint via the speed setpoint step

change measuring function. The measuring function has preselected the measurement for

the speed setpoint and the torque-generating current.

.SBQLVRSWLPXP

.SBQLVWRRODUJH

RYHUVKRRWV

.SBQLVWRRVPDOO

GDPSHGUHVSRQVH

ൺ2.

ൺQRW2.

ൺ2.QRWRSWLPXP

Figure 3-16 Setting the proportional gain Kp

Parameter overview

See "Speed controller".

3.11

Sensorless operation (without an encoder)

NOTICE

The operation of synchronous motors without an encoder must be verified in a test

application. Stable operation in this mode cannot be guaranteed for every application.

Therefore, the user will be solely responsible for the use of this operating mode.

Description

This allows operation without an encoder and mixed operation (with/without encoder).

Encoderless operation with the motor model allows a higher dynamic response and greater

stability than a standard drive with V/f control. Compared with drives with an encoder,

however, speed accuracy is lower and the dynamic response and smooth running

characteristics deteriorate.