4 motion control with profinet, After the beginning of the cycle – Efficient Networks Siemens Sinamics S120 User Manual

Page 448

Communication PROFIBUS DP/PROFINET IO

10.3 Communications via PROFINET IO

Drive Functions

448

Function Manual, (FH1), 07/2007 Edition, 6SL3097-2AB00-0BP4

10.3.4

Motion Control with PROFINET

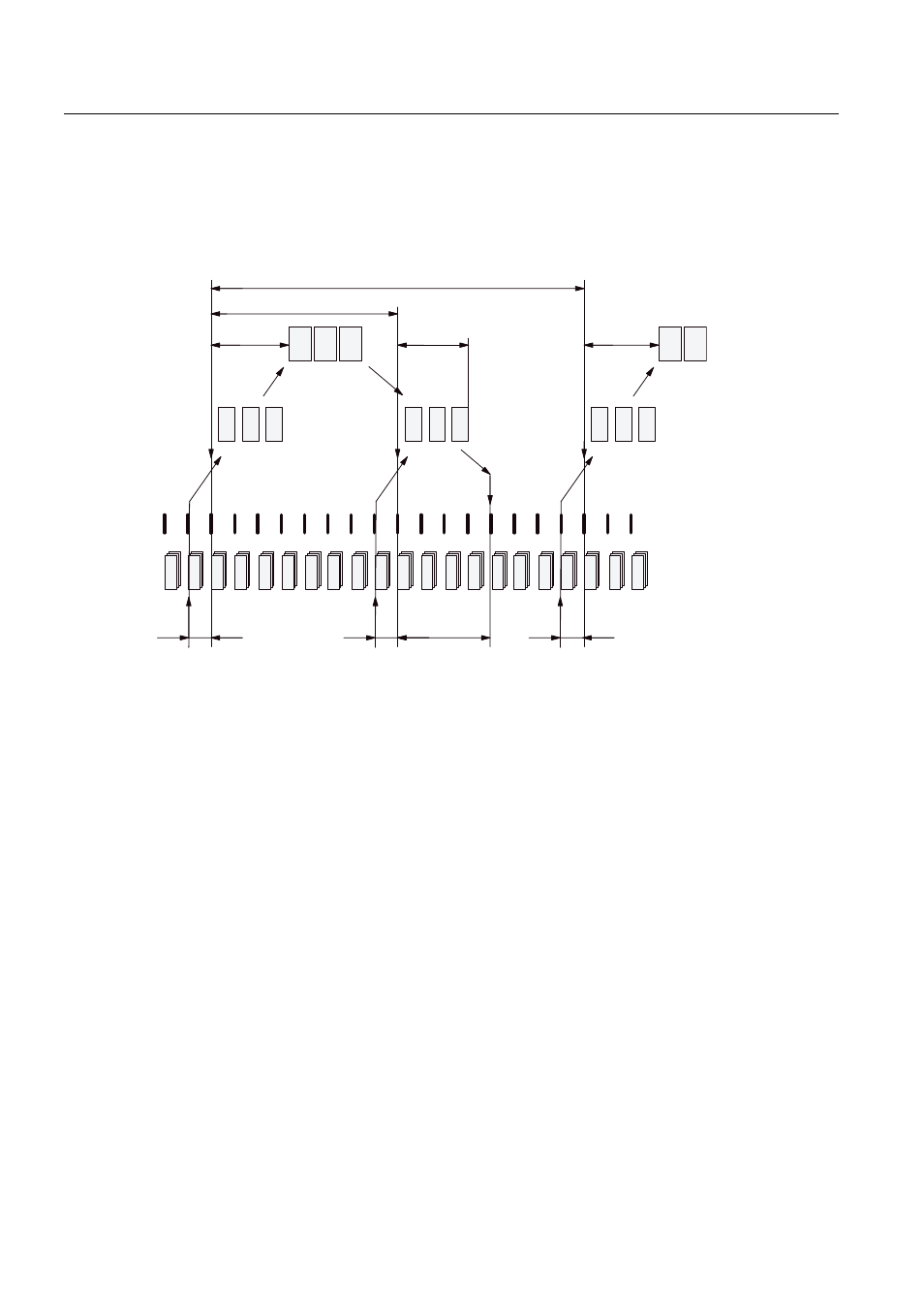

Motion Control/Isochronous drive link with PROFINET

5

'[

'[

'[

'[

'[

'[

'[

'[

'[

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5 5

5

5 5

,2'HYLFH

WR

6SHHG

FRQWUROF\FOH

3RVLWLRQFRQWUROOHU

F\FOH

&RQWUROOHU

3RVLWLRQFRQWUROOHU

7

&$&)

[7

'&

&$&)

7

'&

7

&$B6WDUW

7

&$B6WDUW

7

&$B9DOLG

7

,2B,QSXW

7

,2B,QSXW

7

,2B2XWSXW

7

,2B,QSXW

Figure 10-48 Motion Control/Isochronous drive link with PROFINET, optimized cycle with CACF = 2

Sequence of data transfer to closed-loop control system

1. Position actual value G1_XIST1 is read into the telegram image at time T

IO_Input

before the

start of each cycle and transferred to the master in the next cycle.

2. Closed-loop control on the master starts at time T

CA_Start

after each position controller

cycle and uses the current actual values read previously from the slaves.

3. In the next cycle, the master transmits the calculated setpoints to the telegram image of

the slaves. The speed setpoint command NSOLL_B is issued to the closed-loop control

system at time T

IO_Output

after the beginning of the cycle.