Functional principle, Function modules 7.10 dcc axial winder – Efficient Networks Siemens Sinamics S120 User Manual

Page 284

Function modules

7.10 DCC axial winder

Drive Functions

284

Function Manual, (FH1), 07/2007 Edition, 6SL3097-2AB00-0BP4

0DWHULDOGHQVLW\ 6FDOLQJ

)L[HGPRPHQWRILQHUWLD

0RWRUVSHHG

*HDUEORFN

*HDUUDWLR

0D[LPXPZLQGLQJ

GLDPHWHU

0RWRUVSHHG

:LQGHUVSHHG

$FFHOHUDWLRQWRUTXHPRWRUVLGH

&RUHGLDPHWHU

&XUUHQWGLDPHWHU

0DWHULDOYHORFLW\

0DWHULDOZLGWK

DMIN

DMAX

W

n

2

n

1

:

M

b

V

OFS

D

n

1

:

n

2

:

M

b

:

GF = n

1

/n

2

SCL

DEN

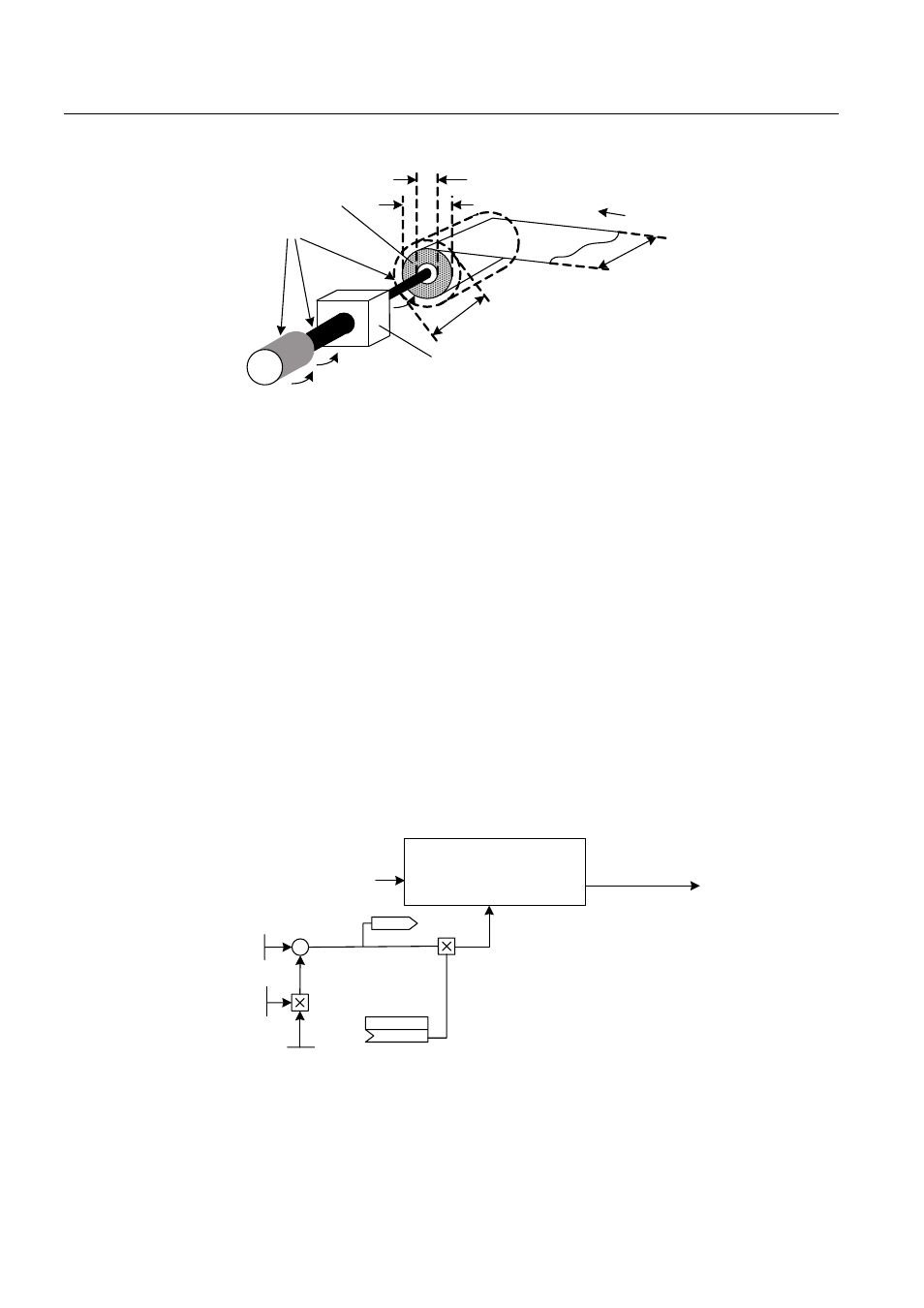

Figure 7-21 Axial winder setup

Functional principle

To maintain a constant tension of the continuous web, the drive moment is increased in a

linear manner while the winding diameter increases, or decreased while the winding

diameter decreases.

To protect the winding material during the winding process, the tension is reduced according

to a characteristic curve when the winding diameter increases.

The calculation of the continuously changing moment of inertia permits a torque pre-control

during a steady decrease or increase of the winder speed.

By using a sensor, a speed controlled operation of the winder is possible. The winder can be

operated without an encoder by controlling the tension moment, with two scaling parameters

p1552 and p1554 for tension moment limitation (see torque limitation).

Calculation of the moment of inertia for torque pre-control

The function diagram below shows the calculation flow for SERVO control with encoder [FP

5042] / without encoder [FP 5210]:

0RW0RP,QHUW5DWLR

>@

S

0RW0BLQHUWLD

>NJP@

S

$FFHOHUDWLRQFDOFXODWLRQ

6HUYRZLWKHQFRGHU>@

6HUYRZLWKRXWHQFRGHU>@

0BSUHFRQWUROB

>@

/RDGPRP

RILQHUWLD

>NJP@

S

r1493

p1497

1

+

+

dn/dt

Figure 7-22 Torque pre-control for SERVO control