Efficient Networks Siemens Sinamics S120 User Manual

Page 243

Function modules

7.8 Closed-loop position control

Drive Functions

Function Manual, (FH1), 07/2007 Edition, 6SL3097-2AB00-0BP4

243

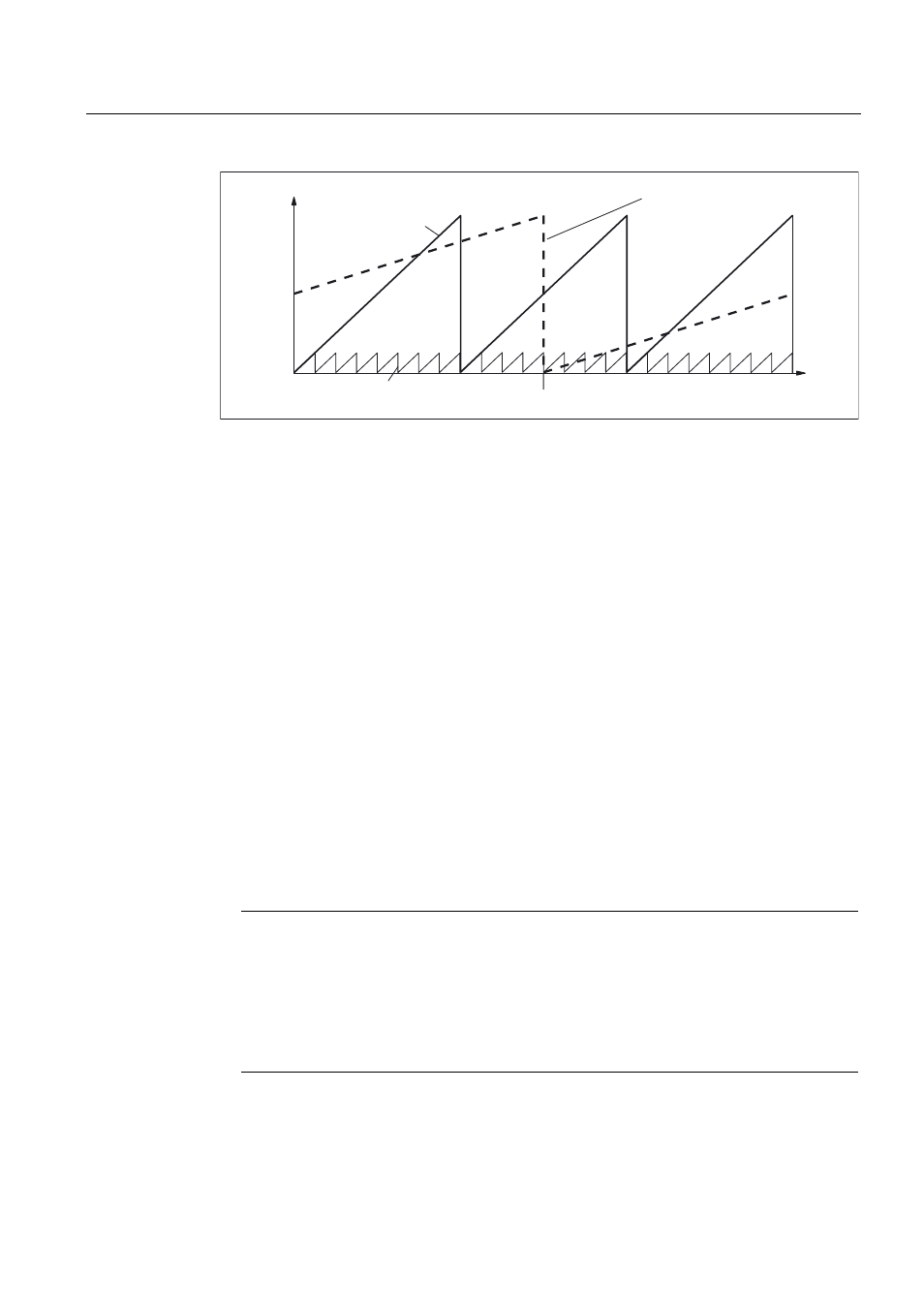

3RVLWLRQDEVROXWHHQFRGHU

(QFRGHUUHYROXWLRQV

([WHQGHGSRVLWLRQDUHD

WKURXJKYLUWXDOPXOWLWXUQ

LQWHUQDOO\PDSSHG

WR(26DUHD

U

Figure 7-10 Position tracking (p2721 = 24)

In this example, this means:

Without position tracking, the position for +/- 4 encoder revolutions about r2521 = 0 LU can

be reproduced.

With position tracking, the position for +/- 12 encoder revolutions (+/- 12 load revolutions with

load gearbox) can be reproduced (p2721 = 24).

Practical example:

For a linear axis, the value for p2721 is set to 262144 for an encoder with p0421 = 4096.

That means, +/- 131072 encoder revolutions or load revolutions can be reproduced in this

way.

For a rotary axis, a value for p2721 = p0421 is set for an encoder.

Configuration of the load gear (p2720).

The following points can be set by configuring this parameter:

● p2720.0: Activation of position tracking

● p2720.1: Setting the axis type (linear axis or rotary axis)

Here, a rotary axis refers to a modulo axis (modulo offset can be activated through

higher-level control or EPOS). With a linear axis, position tracking is mainly used to

extend the position area (see section: Virtual multiturn encoder (p2721)).

● p2720.2: Reset position

Note

If position tracking of the load gearbox is activated after an adjustment p2507=3 has been

made, the adjustment will be reset.

Another adjustment will reset the position (overruns).

Position tracking can be activated in the FW2.5 SP1 only for a single DDS.

If multiple DDS are configured, it will not be possible to active the position tracking

function.