Efficient Networks Siemens Sinamics S120 User Manual

Page 209

Basic functions

6.14 Position tracking

Drive Functions

Function Manual, (FH1), 07/2007 Edition, 6SL3097-2AB00-0BP4

209

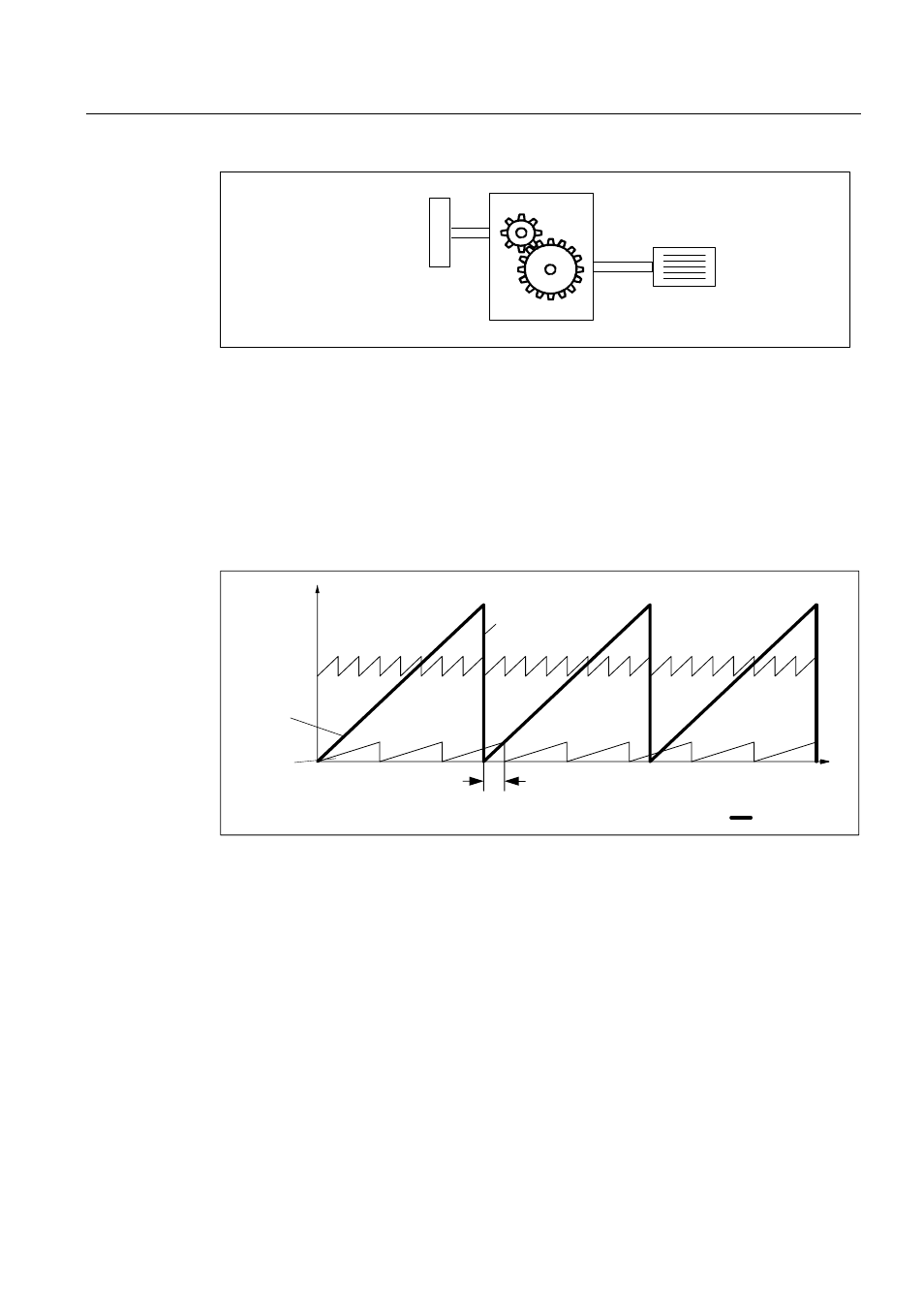

0RWRUORDG

0HDVXULQJJHDU

(QFRGHUV

WHHWK

WHHWK

Figure 6-11 Measuring gearbox

In order to determine the position at the motor/load, in addition to the position actual value of

the absolute encoder, it is also necessary to have the number of overflows of the absolute

encoder.

If the power supply of the control module must be powered-down, then the number of

overflows must be saved in a non-volatile memory so that after powering-up the position of

the load can be uniquely and clearly determined.

Example: Gear ratio 1:3 (motor revolutions p0433 to encoder revolutions p0432), absolute

encoder can count 8 encoder revolutions (p0421 = 8).

3RVLWLRQ

RYHUIORZ

0RWRU

ORDGSRVLWLRQ

2IIVHWIRUHQFRGHURYHUIORZ

3RVLWLRQ

0RWRU

(QFRGHUUDQJH

(QFRGHU

UHYROXWLRQV

Figure 6-12 Drive with odd-numbered gears without position tracking

In this case, for each encoder overflow, there is a load-side offset of 1/3 of a load revolution,

after 3 encoder overflows, the motor and load zero position coincide again. The position of

the load can no longer be clearly reproduced after one encoder overflow.

If position tracking is activated via p0411.0 = 1, the gear ratio (p0433/p0432) is calculated

with the encoder position actual value (r0483).