Speed corrections, Winding bemf shape correction, 1 winding bemf shape correction – ElmoMC SimplIQ Digital Servo Drives-Bell Command Reference User Manual

Page 300

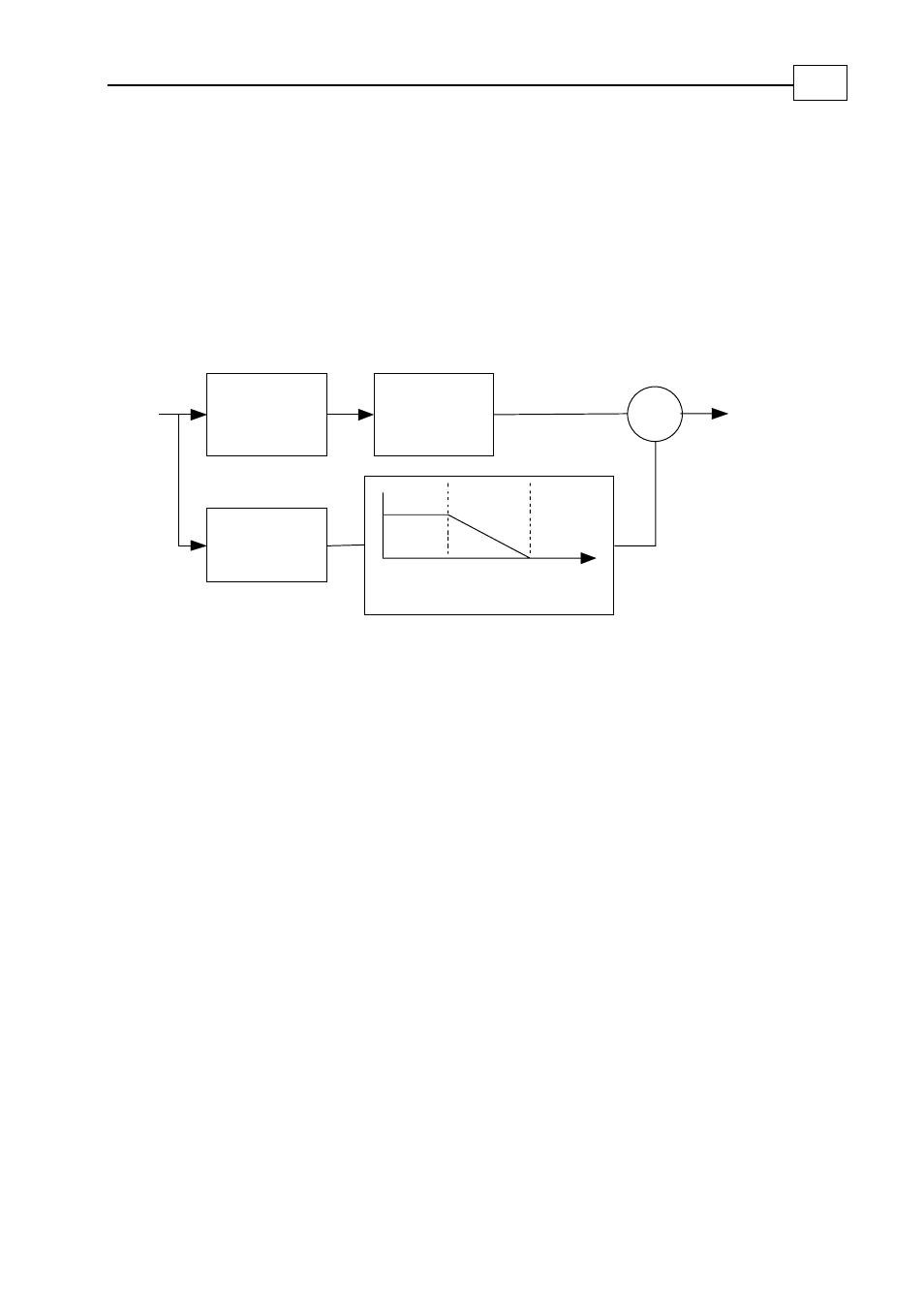

Because of the cogging, motor motion may be unsmooth. The cogging correction

function automatically generates torque additions that compensate for the cogging

torque.

Cogging correction works very well at slow speeds. At high speeds, cogging becomes

a high frequency disturbance. On the one hand, cogging correction becomes less

important because the high frequency less disturbs motion; on the other hand, the

correction becomes less efficient due to the limitations of the current amplifier.

Field

angle

Predictor for current

loop delay compensation

[3]

e

PF

s

−

Lookup

table

/

d dt

1

PF[4]

PF[5]

ω

Cogging

correction

torque

×

Speed dependent gain

Figure 21: Cogging correction scheme

Therefore,

SimplIQ

uses the cogging correction scheme above in order to apply

cogging correction at reasonable speeds, reducing the correction as speed increases.

The cogging correction may be enabled and disabled as a whole, using the parameter

PN[2].

9.3. Speed

Corrections

The

SimplIQ

is a full vector drive. It compensates for the following disturbances:

- Winding BEMF shape.

- Voltage required for driving the motor inductance.

All the speed corrections may be disabled or enabled as a whole using the parameter

PN[3].

9.3.1

Winding BEMF Shape Correction

The BEMF model serves the following purposes:

- Current scale corrections, in order to minimize ripple torques.

- Winding shape correction, for better current control in the presence of EMF.

SimplIQ for Steppers Application Note

The Current Controller

MAN-STECR (Ver. 1.1)

101