ElmoMC SimplIQ Digital Servo Drives-Bell Command Reference User Manual

Page 274

Example:

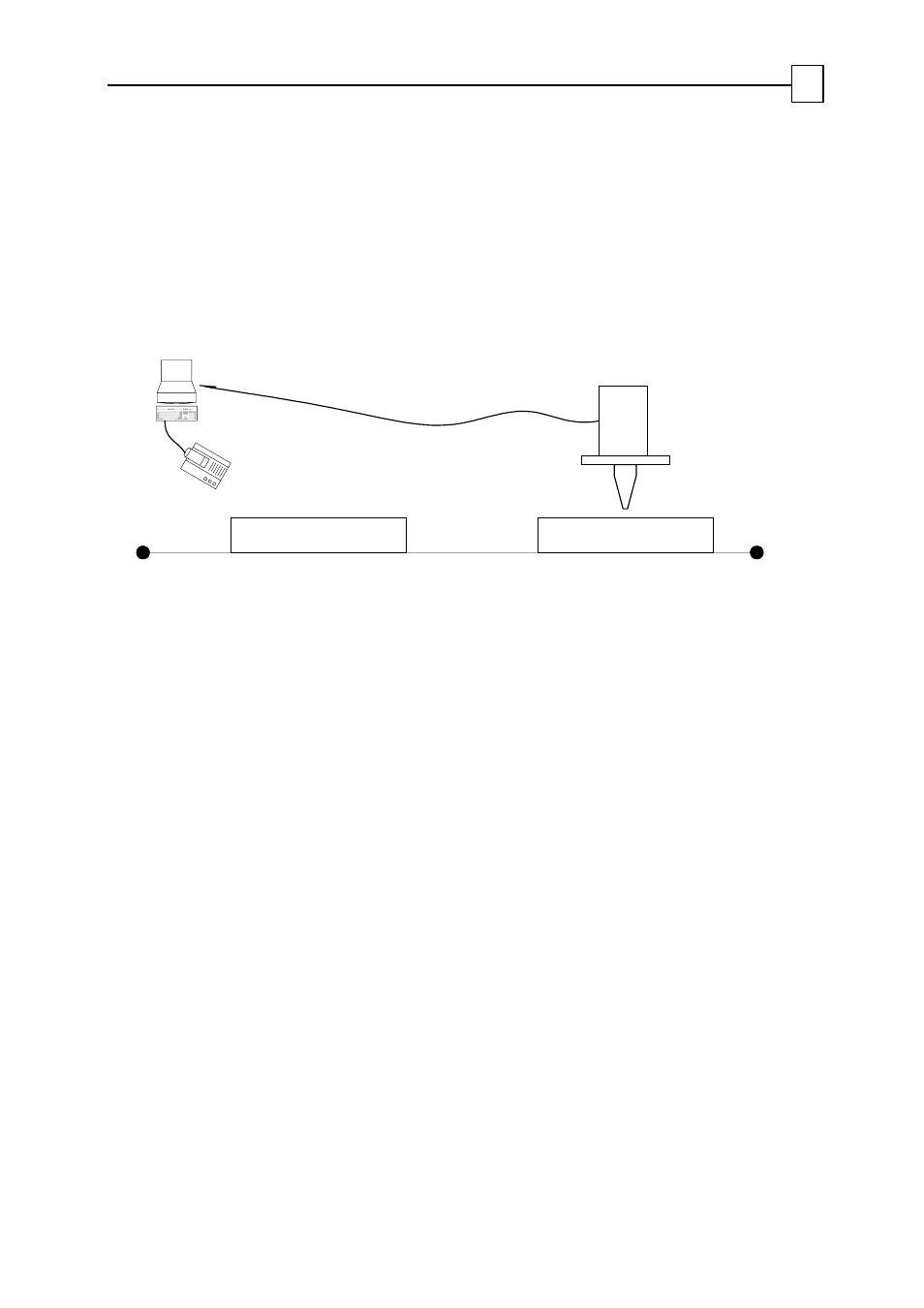

In the previous example of the chocolate bear, it was assumed that the bear drawing

could be programmed one time only. In many food applications, however, the products

to be worked on (the cake in the example) are not placed precisely on the conveyor or

their shapes may be irregular. A camera images the next coming product and the image

is analyzed to form the next motion path. The motion path for the analyzed image is

communicated to the drive by the system controller while the drive works on a

previously-programmed path, as depicted in the following figure:

Cake

Drawing x-y m anipulator

station

Next cake

Cam era station

CAN

Cam era

Assume that the drive at the x-y manipulator station runs ECAM table entries

ET[1]…ET[100]. In the meantime, the system controller programs the next shape to run

ET[101]…ET[200]. The preferred method to achieve this is to use the fast CAN ECAM

points protocol. While the x-y manipulator works on ECAM table entries

ET[101]…ET[2000], the system controller programs ET[1]…ET[100] again, and so on.

The AUTO_RLS program of the previous example is now slightly modified to:

function AUTO_I1

DIN#1 has operated an already-programmed HY

homing process to synchronize the following input.

EM[5]=1 + NextSegment * 100; EM[2]=100 * (1 + NextSegment);

EM[1]=1…OB[1]=1; FR=1;

The system controller manipulates the user program

variable NextSegment to signal which part of the table

to use next. The AUTO_I1 line selects the ECAM table

portion to use by NextSegment, and then sets EM[1]=1

to activate the new used portion, activating the follower

gain and the chocolate flow.

until (PY >= 2000)

Wait until end of head contour.

…

Continue as in previous example.

return

SimplIQ for Steppers Application Note

The Position Reference Generator

MAN-STECR (Ver. 1.1)

75