K i j ω – ElmoMC SimplIQ Digital Servo Drives-Bell Command Reference User Manual

Page 216

- It does not require any commutation sensor – there is no need to tune the

commutation, and there may even be flexibility or a play between the position

sensor and the motor shaft.

- The position static error is reduced to zero.

- It provides smooth motion at low speed.

Its main drawbacks are:

- Low efficiency, since the holding current exists regardless of the mechanical

output torque.

- Tendency to oscillate if the closed loop controller is tuned to low bandwidth. The

stepper torque is proportional to the position error, so that it generates a

harmonic oscillator with the natural frequency of

T

r

K I

J

ω =

. Here

T

K

is the

motor torque sensitivity, I is the current, J is the motor and load inertia, reflected

to the motor. When tuned to high bandwidth (this requires a good quality

position sensor and no play), the stepper’s natural resonance is almost completely

eliminated.

- When the acceleration limits are not set correctly (PF[29]), the stepper stalls. This

means that it no longer generates DC torque or power – it simply vibrates in

place.

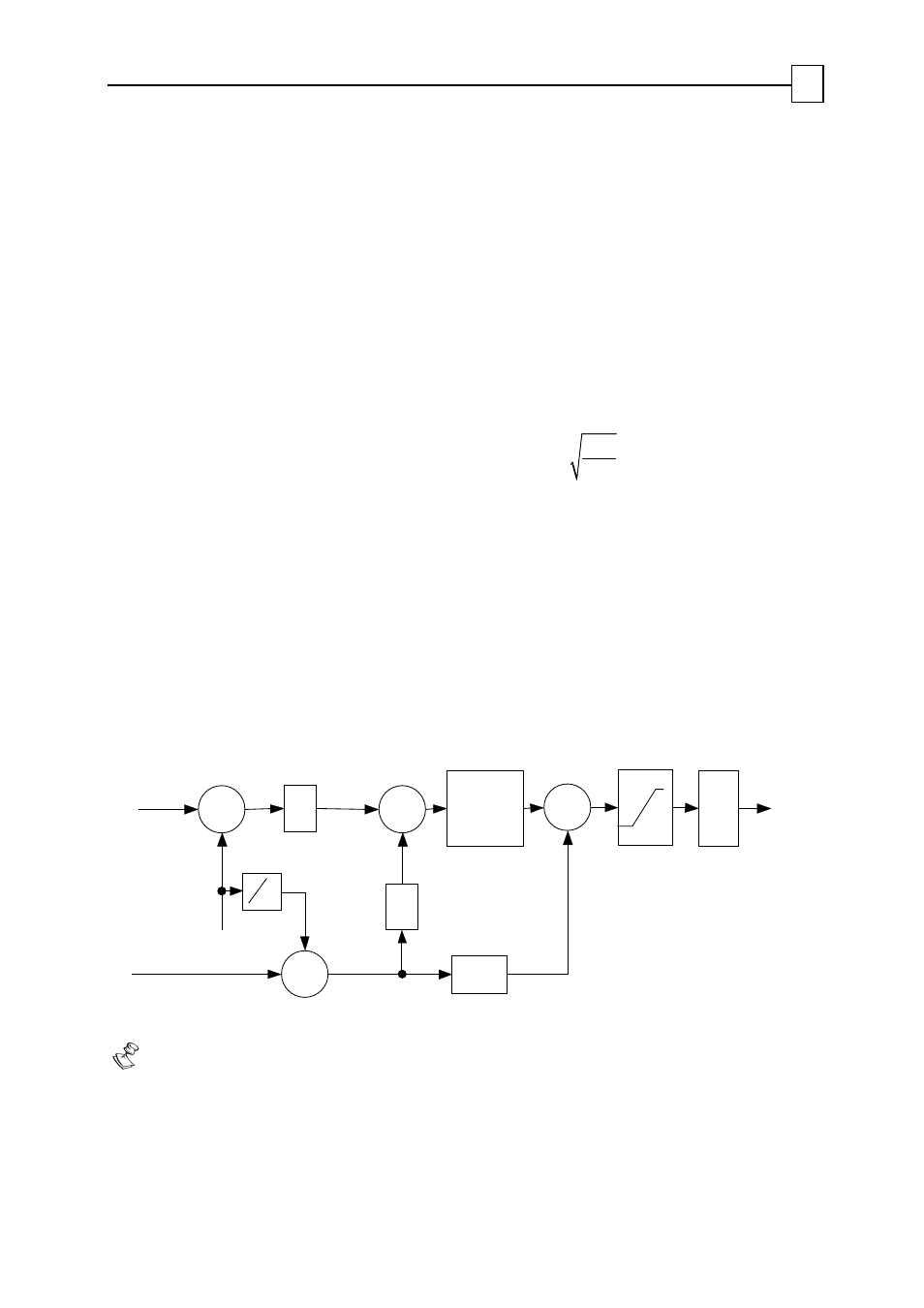

The position controller structure is depicted below.

ˆ

P

K

ˆ

I

K

Σ

Position

command

[counts]

Position

feedback

Σ

Speed

command

[counts/sec]

d

dt

-

-

Σ

High

order

filter

Σ

FF(2)

Speed &

Acceleration

limit PF[29]

K1

Electrical

angle, rev.

• The parameter KF[29] tunes the acceleration limiter, which prevents the controller from

demanding too great accelerations, as too great accelerations may cause a stepper to

stall. This parameter sets the ratio between the current level in [A] and the permitted

drive acceleration in encoder counts/sec

2

.

SimplIQ for Steppers Application Note

Unit Modes

MAN-STECR (Ver. 1.1)

17