Program creating – IAI America XSEL-S User Manual

Page 90

5. Program Creating

84

5.

Program Creating

Operations are performed using a program that sets positioning data and determines the operation

sequence and how each operation is performed. How operations are performed in each of the two

operation modes used by the RC gateway function is explained below.

The program is in common for Fieldbus and SIO Types.

Method to use position data in X-SEL

Operations are performed by setting the position data of the slave axis in the master controller (X-SEL

controller).

Although up to 512 points can be set per axis, take note that increasing the number of effective axes

decreases the number of specifiable positions.

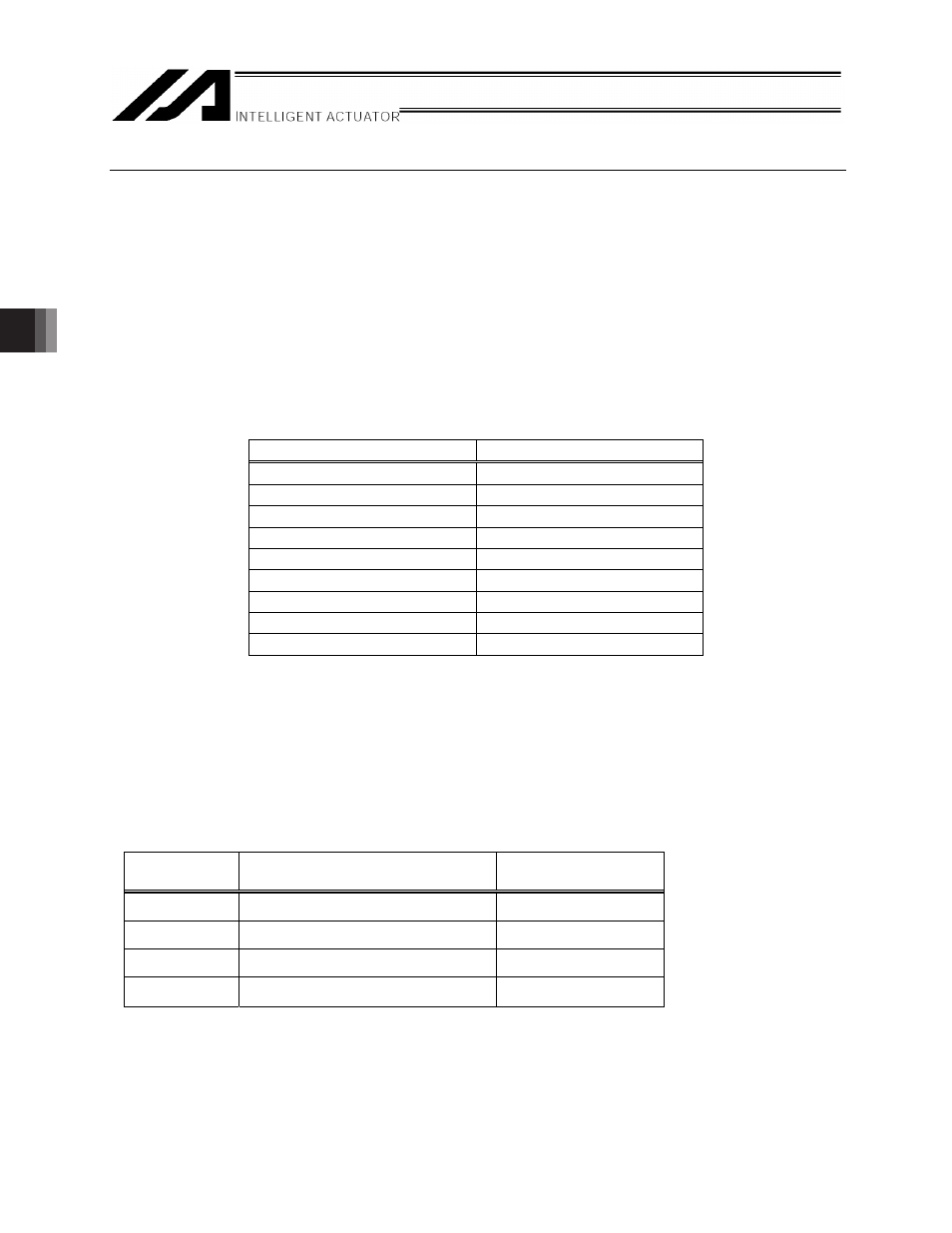

The table below shows the relationship of the largest axis number among the connected axes and the

maximum number of position data points that can be set.

(The same relationship applies to the number of positions available with each ROBONET, MSEP and

MSCON axis.)

Largest axis number

Number of positions

0 to 7

512

8

455

9

409

10

372

11

341

12

315

13

292

14

273

15

256

Method to use position data in RC

Operations are performed with an X-SEL program using the position data set in each slave-axis controller

(RC controller or ROBONET, MSEP and MSCON).

The number of positions corresponds to whatever is permitted for the each slave controller.

The maximum number of positions for each axis is determined by each controller as well as the applicable

parameters set in the controller. Refer to the operation manual for each controller.

The maximum number of position data for each axis when using the method to use the position data in RC

in Fieldbus Type

Controller

Operation Mode

Max. Number of

Position Data

MSEP

Positioner 1 Mode

256

MSCON

Positioner 1 Mode

256

A/PCON

Position / Simple Direct Mode

768

SCON-CA

Position / Simple Direct Mode

768