INFICON STC-2000A Thin Film Deposition Controller Operating Manual User Manual

Page 245

p

STC-2000A DEPOSITION CONTROLLER

y

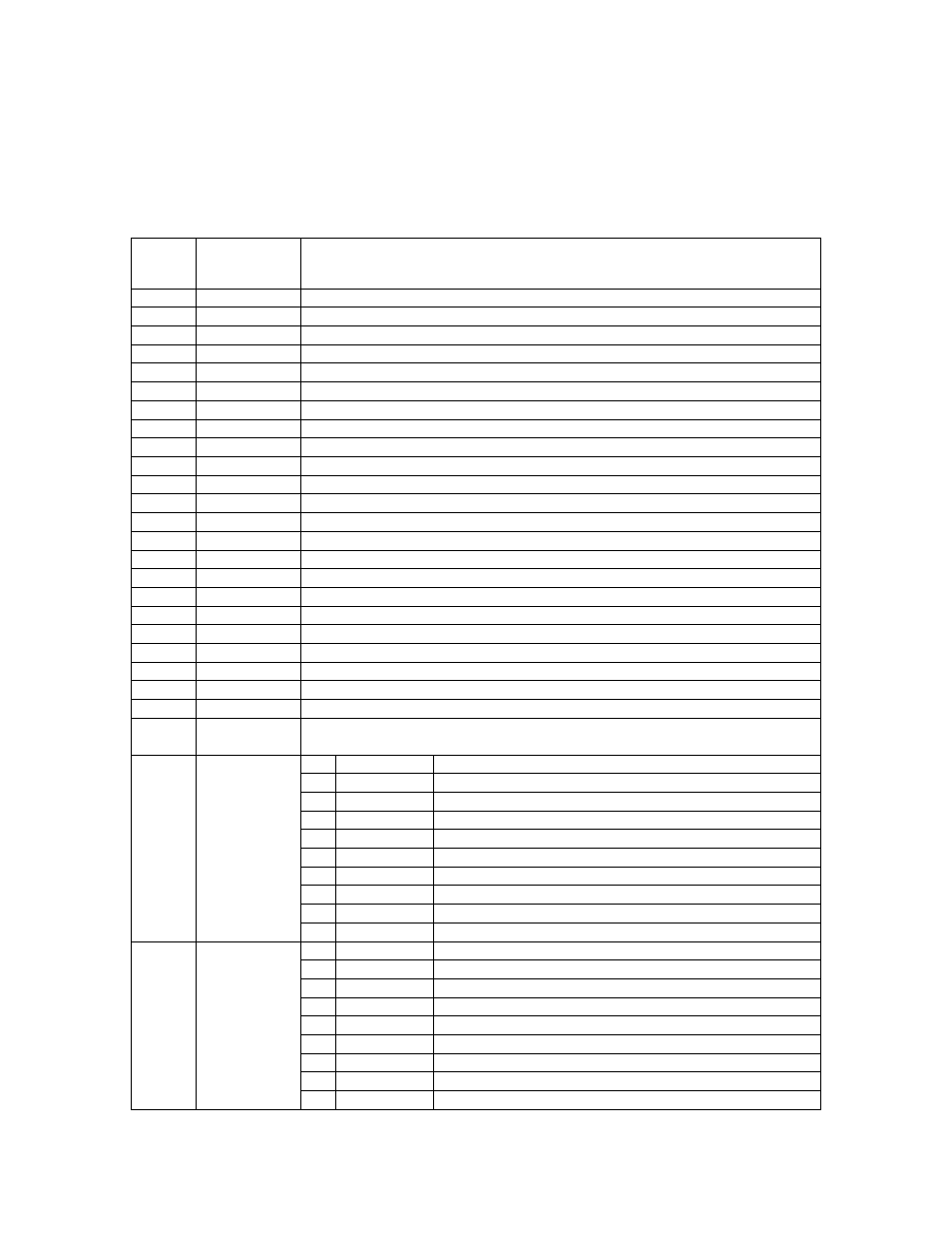

The set of L commands are used to read the process accounting information from the STC-2000A

to the host computer. There are 2 parameters that are passed. The first is a single digit from 0 through 3.

This indicates which set of parameters is to be read. The number 0 is the most recent and 3 is the oldest.

The second parameter defines what piece of information will be read. Table 6.18 lists the numbers and

parameters.

Process Accounting

Index

Address

/ ID

Mnemonic Description

0

PA_date

Date of process run, calendar MM/DD/YY as 6 digits.

1

PA_time

Time, clock hrs/mins in military HH:MM .

2

PA_rnno

Run #, 0.9999. Followed by 'T' if a test mode run.

3

PA_procid

Process #, 1..9 if sequencing, 0 if non-sequencing.

4

PA_lyrn

Layer number if sequencing, 1..99, # of step in sequence.

5

PA_flmn

Film # , 1..50.

6

PA_map

Source-Sensor Map reference number, 1..10.

7

PA_source

Source channel for power, 1..2 or 0 if invalid source.

8

PA_pocket

Pocket number associated with film. 0..63.

9

PA_tdep

Time of shutter open in seconds.

10 PA_ethk Ending

thickness.

11 PA_erate Ending

rate.

12

PA_pwrv

Power value at shutter close.

13

PA_loop

Loop accum at shutter close, 0..99.

14

PA_x1use

Life reading for xtal 1 at beginning/end.

15

PA_x2use

Life reading for xtal 2 at beginning/end.

16

PA_x3use

Life reading for xtal 3 at beginning/end.

17

PA_x4use

Life reading for xtal 4 at beginning/end.

18

PA_x5use

Life reading for xtal 5 at beginning/end.

19

PA_x6use

Life reading for xtal 6 at beginning/end.

20

PA_x7use

Life reading for xtal 7 at beginning/end.

21

PA_x8use

Life reading for xtal 8 at beginning/end

22

PA_tproc

Time of process, start to idle or stop.

23

PA_stat

Process run completion status, stopped/why, normal idle, tpwr, etc... from

completion status messages below.

0

NORMAL

normal completion, reached idle.

1

TIMPWR

completed to idle, time power during deposit.

2 BADXTL crystal

bad.

3

REMOTE

remote from I/O system.

4 KEYBRD front

panel

5

MAXPWR

max power condition persisted too long.

6

PENDNT

remote pendant stop.

7

SAFE 1

User Interface subsystem failure.

8

S4 BAD

Measurement module systems failure

9

IO BAD

I/O module/plugin failure.

10

0 BHIE

Measurement Bus Hold failure.

11

INDEXR

Indexer feedback timeout failure

12

INVSRC

Invalid source associated with Map/Film

13

INVSNS

Invalid sensor associated with Map.

14

IO_AX1

I/O auxiliary stop 1

15

IO_AX2

I/O auxiliary stop 2

16

IO_AX3

I/O auxiliary stop 3

17

IO_AX4

I/O auxiliary stop 4

18

QUALDLY

Failed quality while in shutter delay

SECTION 6.XX

page 245 of 292