INFICON STC-2000A Thin Film Deposition Controller Operating Manual User Manual

Page 195

p

STC-2000A DEPOSITION CONTROLLER

y

instruments

STOP

INC

DEC

MANUAL POWER

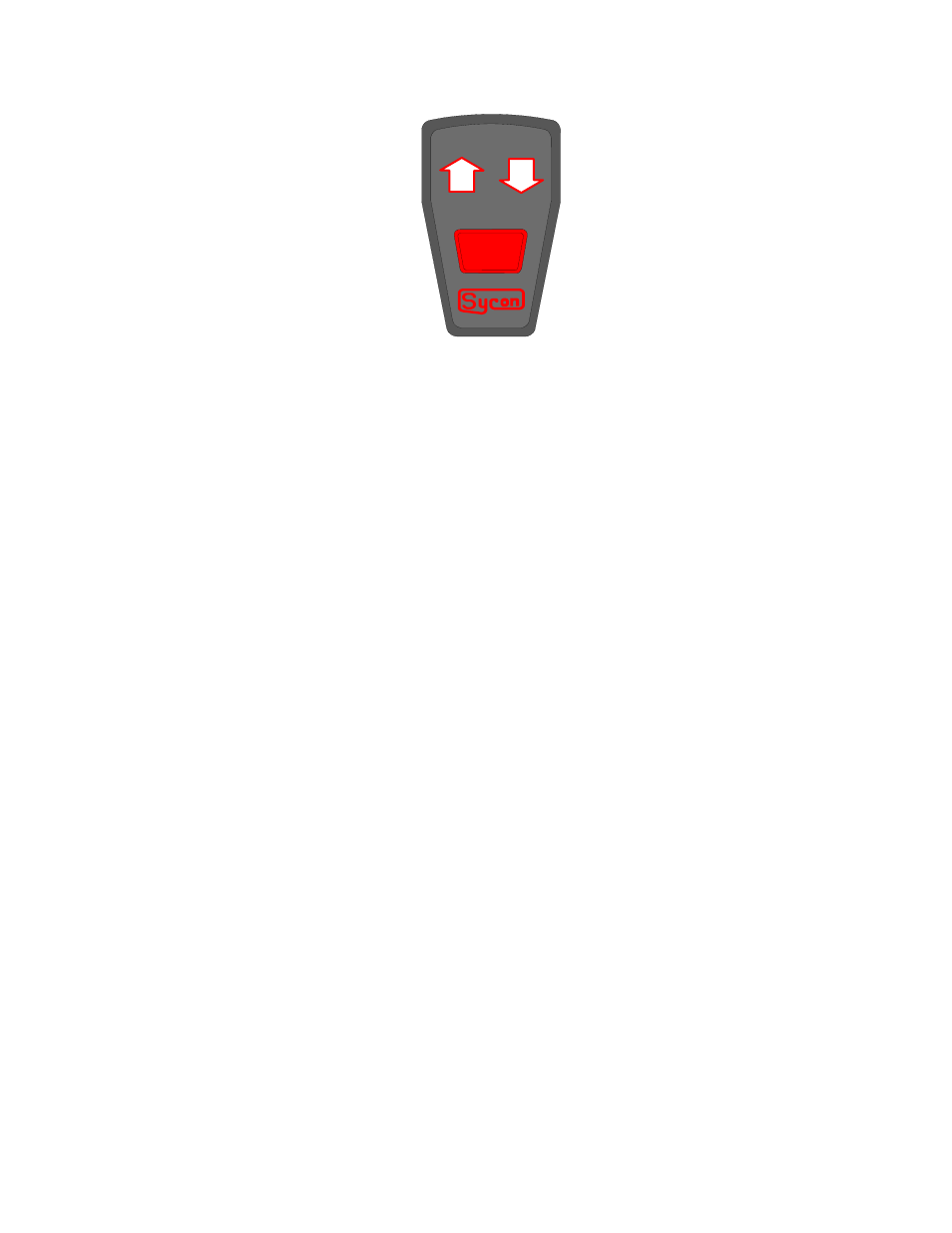

Figure- 5.13: Hand Controller (also called a Pendant).

One common usage of a remote stop key is when the STC-2000A is used in conjunction with an

optical monitor. An I/O rung is added which triggers an external final thickness. Thus an operator viewing

the optical monitor results can manually terminate the deposition remotely by adding a single I/O rung,

which provides this function.

1: I91 I72 ! & T217

The input portion of this statement tests the status of the STOP key on the Hand Controller (I91)

and logically 'ANDs' it with the complement of the manual mode state (I72!). The output portion of this

statement triggers the final thickness when the input conditions are met. With this I/O statement installed,

pushing the STOP key on the Hand Controller while in non-manual deposition will cause the deposition to

be terminated as if the set point final thickness had been achieved. In practice, the set point is set slightly

above the predicted desired thickness and then the deposition terminates either manually by the operator or

automatically at some safety thickness if the operator misjudges his optical results. Likewise the INC and

DEC keys could be programmed to raise and lower the vacuum chamber or do some other useful tasks by

adding an additional I/O rung or two.

Four front panel LED indicators ( for output) and four fixed front panel function keys (for input)

have been assigned ID's which allow them to be incorporated into an I/O program as are the pendent keys

(See Table 5.3, ID#s: 64 through 71). The leftmost LED has an ID# of 64 and the following LED ID#s

increment consecutively to the rightmost LED whose ID# is 67. The leftmost function key has an ID# of 68

and the key ID#s increment consecutively to the rightmost function key whose ID# is 71. The LEDs can be

used to indicate progression through a process, a single event, a series of unrelated single events, indicate

that a function key has accomplished its programmed function, etc. The function keys can be used to

trigger events, provide or release a pause in a process, provide a decision capability by waiting for the press

of one of two (or three) keys at some point in a process, etc.

SECTION 5.19

I/O ERROR MESSAGES

When entering or editing an I/O program several Error Messages might occur. These messages

indicate that the rung which was changed contains an error in form or content. The following error

messages may appear during the process of entering an I/O rung or trying to leave an I/O program which

has been altered.

ERROR Probable

Cause

Phase Error

Multiple use of an output ID code somewhere in the I/O program. The following

I/O program will cause a Phase Error message:

1: I1 O7

2: I2 O7

It is desired to have both Remote input 2 & 3 (ID#'s 1 & 2) close Output Relay 1

(ID# 7). The proper way to do this is to logically combine the input portion of

the I/O statements as follows:

1: I1 I2 ¦ O7

SECTION 5.XX

page 195 of 292