INFICON STC-2000A Thin Film Deposition Controller Operating Manual User Manual

Page 132

p

STC-2000A DEPOSITION CONTROLLER

y

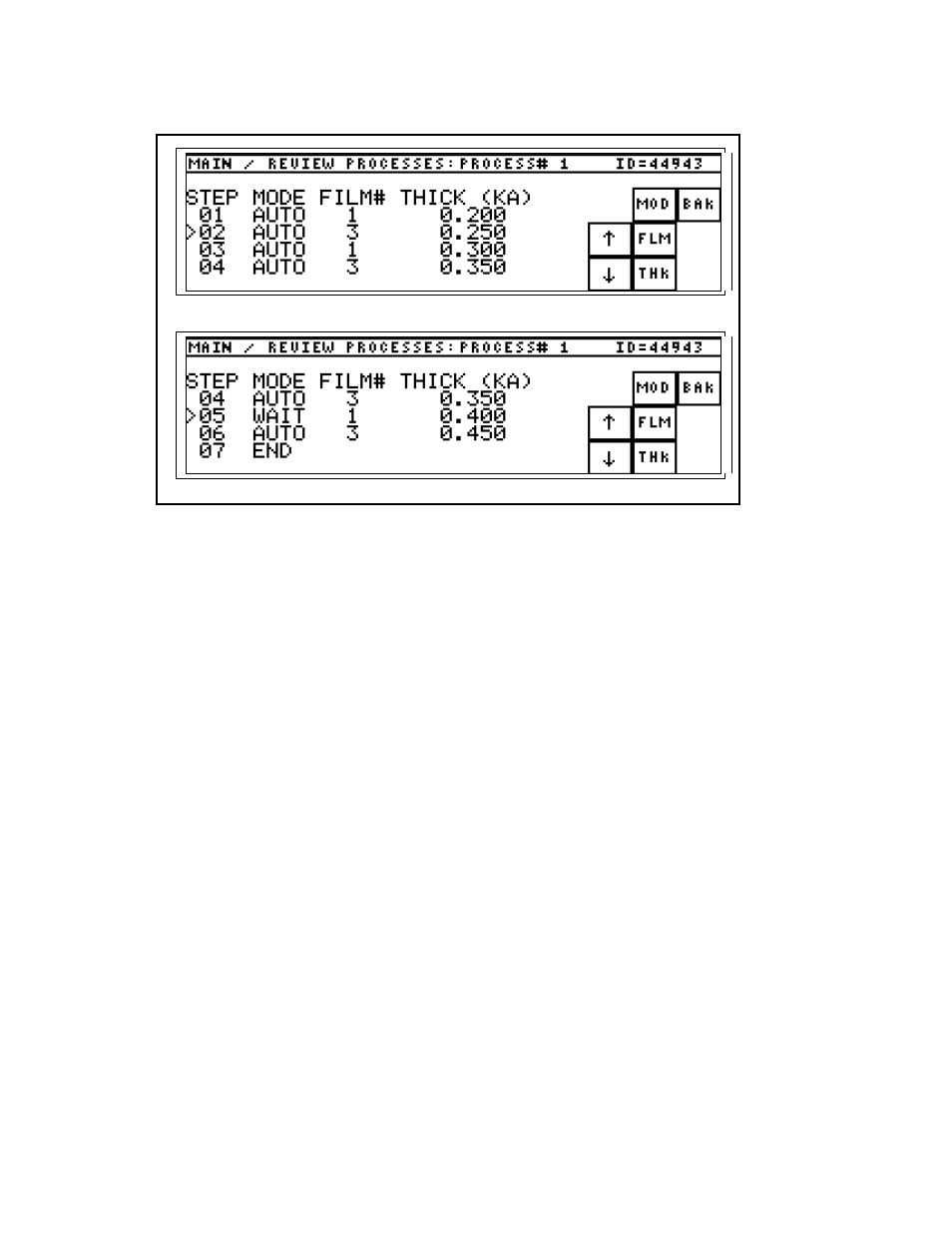

Figure- 3.18: Six Layer Test Process.

After programming the above process, note the five digit number that appears in the upper right

area of the screen labeled ID (a checksum for the seven step process sequence). This is a unique checksum

determined by the numbers and terms programmed into the process. If you have programmed the process

identical to the above example the checksum number will be 44943. After programming an actual process,

it is useful to record this number. If you ever have to duplicate a process program all of the data entry can

be verified by comparing this number to original process checksum. See section 2.21: check sum

validation.

Feel free to repeat the above procedural elements with variations that still complete the desired goal as

many alternative paths are possible.

Programming Film 1 & Film 3

Film Programming

To complete the programming of Process 1, both Film 1 and Film 3 need to have proper material

and source parameters. To edit or review a film program push the fixed MENU key from the Run Time

screen to bring up the Main Menu. Press the digit associated with and to the right of the REVIEW FILM

key. The digit entry represents the FILM#. Next, press the REVIEW FILM key to select the FILM # to

review/edit as identified by the digit entry. At this point, you will see a display similar to Figure 3.18. The

current parameter will probably be different as the last parameter edited is 'remembered' by the STC-2000A

and this is what will be shown on your display. If the edit film is not Film 1 at this point, pushing the F#

key will allow selection of the Film # as the desired film program to be edited. Pushing the fixed STATUS

key returns you to the RunTime screen.

There are several parameters on each film that need to be programmed in order to do a sample test

run. For Film 1 the parameters that we will change are :

SOAK 1 PWR VALUE to

15.0 %

PWR RAMP 1 TIME

to

1:00

PWR SOAK 1 TIME

to

0:10

DEPOSIT RATE

to

20.0 A/s

MAX PWR LIM

to

100.0%

PLOT VERT SCL V

to

10

SECTION 3.XX

page 132 of 292