INFICON STC-2000A Thin Film Deposition Controller Operating Manual User Manual

Page 123

p

STC-2000A DEPOSITION CONTROLLER

y

one for the I/O rungs (Main Menu: Executive Menu: I/O Setup). See sections 2.5, 2.7, 5.10 and 5.13 for

related details. See the end of section 2.6, Processes: Factory settings vs. purged settings.

Each of the three program types have check sums that can be used to check the integrity of a program

which is a part of a system that has a problem or check the integrity of a program that may have been

inadvertently changed or verify a program that is reentered in its entirety. A group of check sums from the

different programs can be used to uniquely identify an entire deposition process. The programs along with

their check sums should be stored both electronically and on paper. Different processes can be identified by

a text description coupled with constituent programs and their check sums. When a program is known to

be correct, write the check sum number down in a journal of software entries/programs, having method or

recipe attributes being integral to objectives.

Please note that as changes, additions or deletions are edited, the commensurate check sum change will not

become apparent until the modification is accepted (saved) into the program from the temporary

workspace.

The check sum is a five digit hexadecimal number (e.g. 4A6F6, 5204D). The number is prefixed

by the label "ID=" (except for the film parameters check sum, which is prefixed by an "X"). In addition, the

I/O program has, following the "ID=", a letter designator indicating the memory sector in which the

program resides (either an A or B). Using the SWP (swap) key accessed through the MEM key reverses

this.

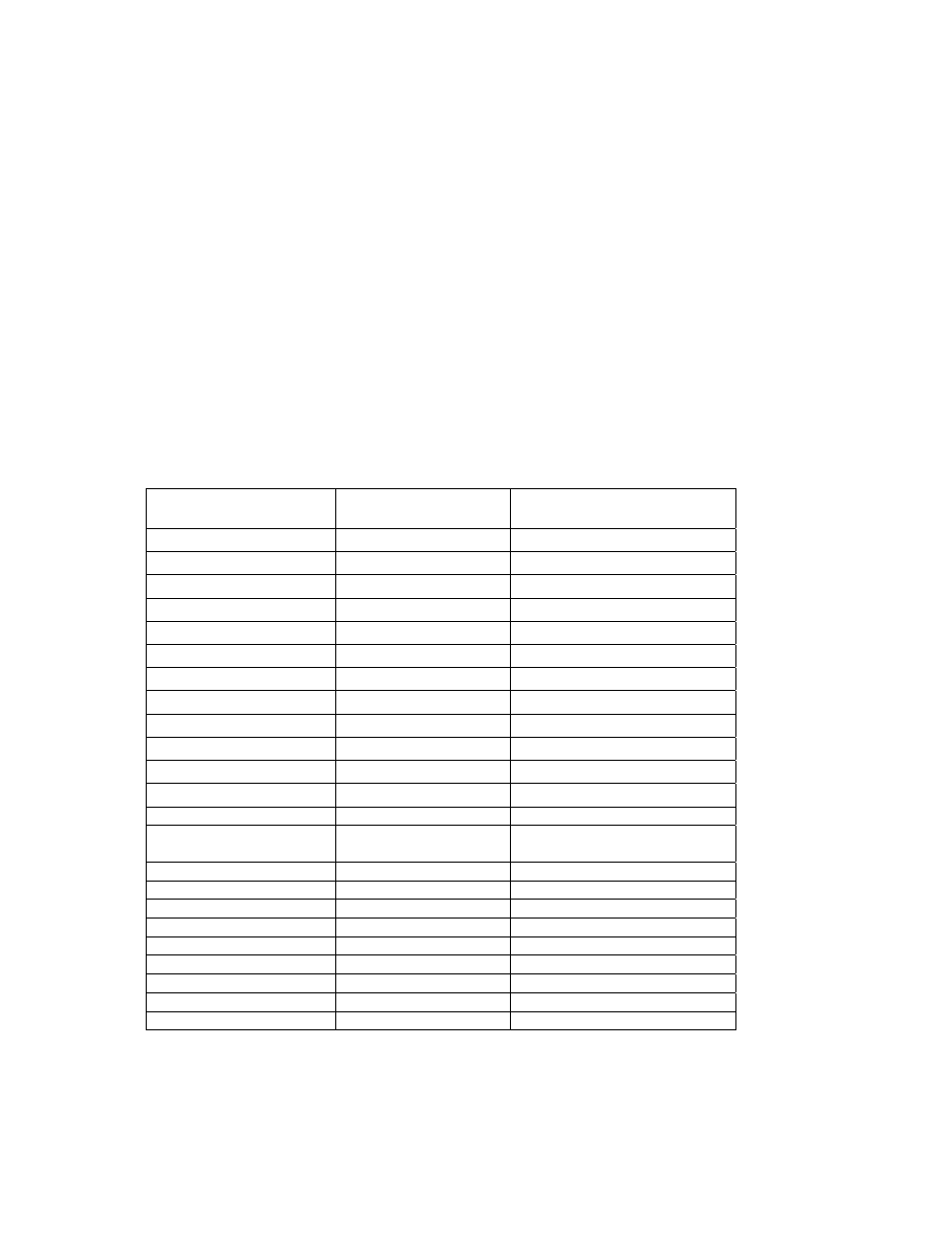

Check sums and paramters after a PURGE or a FACTORY RESTORE are as follows:

After

PURGE

After

FACTORY RESTORE

Review films 1-9:

X17523

X61037

Review Process 1:

ID=00000

ID=55274

Review Process 2:

ID=00000

ID=12121

Review Process 3:

ID=00000

ID=30944

Review Process 4:

ID=00000

ID=24150

Review Process 5:

ID=00000

ID=02503

Review Process 6:

ID=00000

ID=61768

Review Process 7:

ID=00000

ID=09958

Review Process 8:

ID=00000

ID=48200

Review Process 9:

ID=00000

ID=60411

I/O Program A:

ID=A24490

ID=A24490

I/O Program B:

ID=B24490

ID=B24490

RunTime Mode:

Sequencing not

changed

(remains SEQ or NON-SEQ)

Film parameter:

MAX POWER LIMIT

0%

50%

System configuration:

RECORDER FUNCTN:

RATE

POWER

CLOCK TIME:

not changed

not changed

CLOCK DATE:

not changed

not changed

I/O Programs:

cleared not

changed

PROCESS ACCT'ING:

cleared cleared

See section 2.2, Initial Programming Setups (Menu Parameters), for complete listings of parameter states

after factory default memory configuration and purged memory configuration. See next section for optional

external memory save / restore functions.

SECTION 3.XX

page 123 of 292