Wiring procedures – Yokogawa Standalone MW100 User Manual

Page 100

2-12

IM MW100-01E

2.4 Connecting Signal Wires

Wiring Procedures

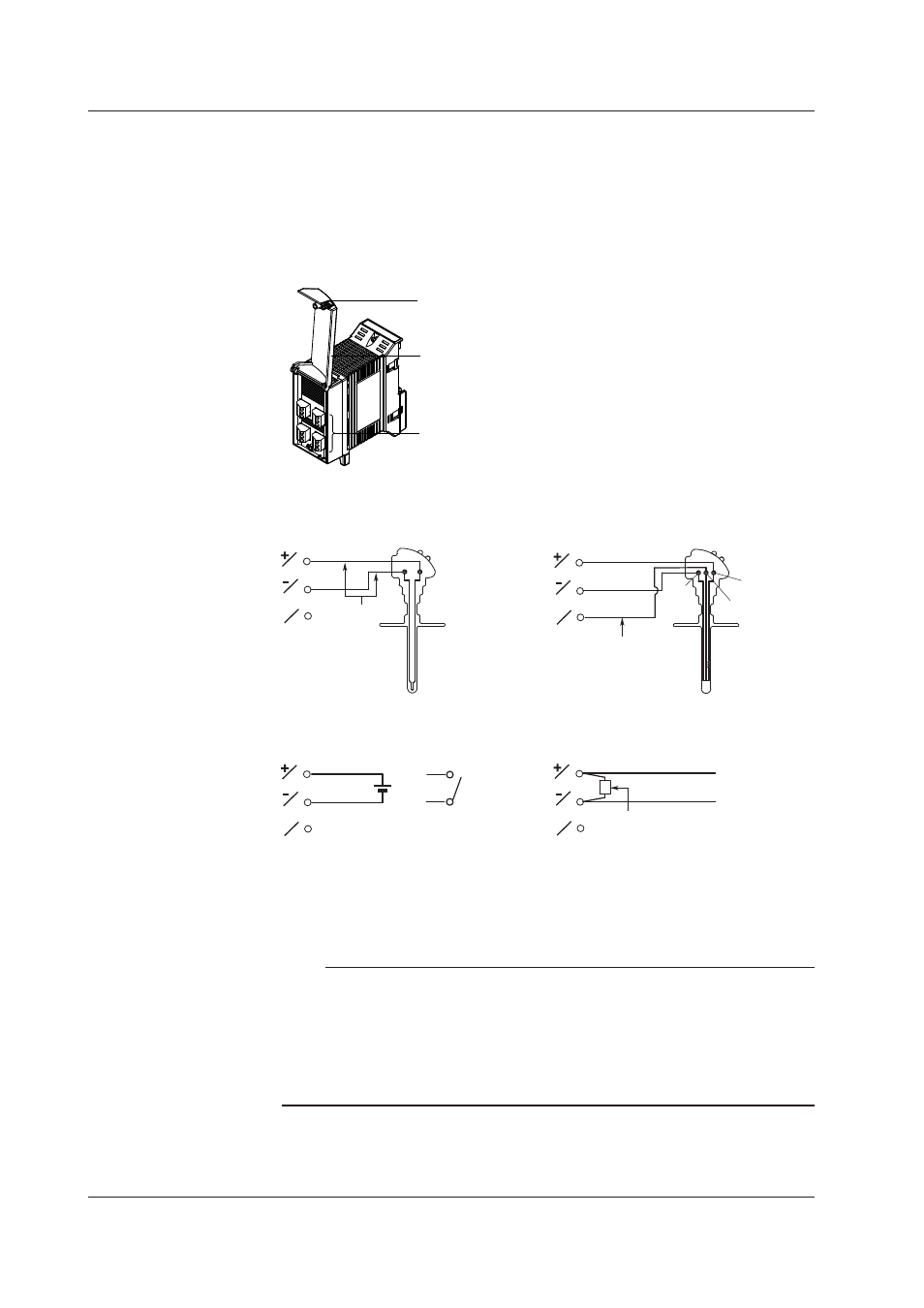

1. Turn OFF the power to the instrument.

2. Loosen the terminal cover attachment screw and lift up the terminal cover.

3. Connect the signal wires to the terminals.

4. Return the terminal cover to the original position and secure it with the screw. The

appropriate screw tightening torque is 0.6 N·m.

Input terminal (clamp terminal)

Terminal cover

4-CH, High-Speed Universal Input Module

Attachment screw for terminal cover

Wiring the Universal Input Module and DCV/TC/DI Input Module

• Thermocouple input

• DC voltage input/DI input (contact)

• RTD input

• DC current input

DC current input

Shunt resistor

Example: For 4 to 20 mA input,

shut resistance values should

be 250 Ω ± 0.1%.

–

+

Lead wire resistance per wire of

10 Ω or less*. Make the resistance

of the three wires equal.

A

b

B

Compensation

lead

b

A

B

b

A

B

b

A

B

* In the case of Pt100

Ω

. 5

Ω

max

for Pt50

Ω

. 1

Ω

max. for Cu10

Ω

.

+

–

DC voltage

input

b

A

B

Contact

or

Terminal type:

Clamp, or screw (in the case of M3: -L30/H3)

Applicable wire size:

For -H04, 0.2 to2.5 mm

2

(AWG24 to12)

For -M10 and -L30 (clamp), 0.14 to 1.5 mm

2

(AWG26 to 16).

Note

• With the 10-CH Medium-Speed Universal Input module, the A and B RTD input terminals

are insulated on each channel, but terminal b is shorted internally on all channels.

• Measurement using RTD cannot be performed with the 30-CH Medium Speed DCV/TC/DI

Input Module.

• When the plate with screw terminal (model 772080) is connected to the 10-CH Medium-

Speed Universal Input Module, the terminal arrangement differs from that of clamp

terminals, so wire according to the markings on the terminal cover.