Calib (calibration) – KEYENCE LT-9001 Series User Manual

Page 102

Common

Operations

and

F

unction

Settings

5

Chapter

E LT-9001-IM

5-16

OUTPUT Settings

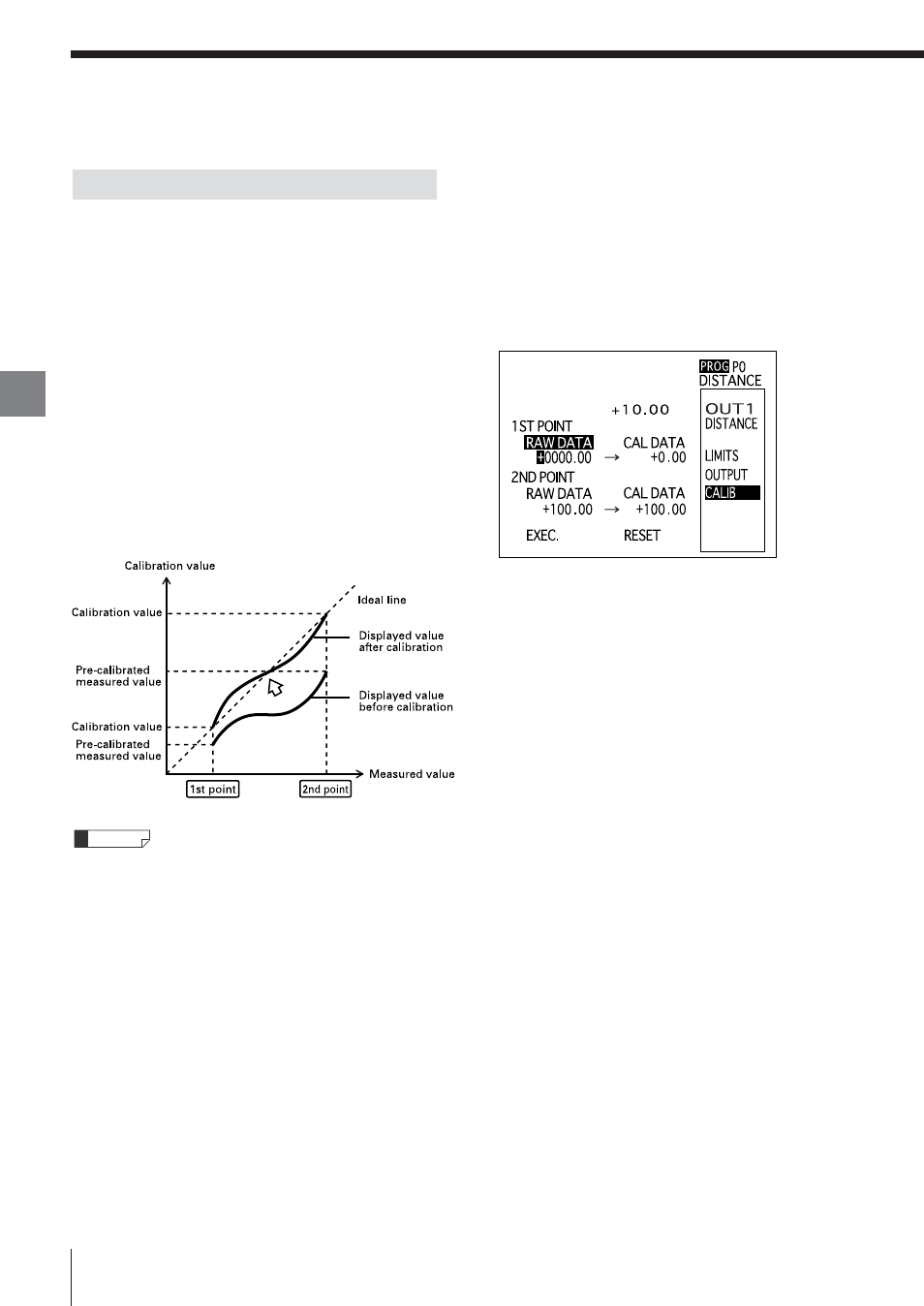

An error may occur in the measured value due to

the surface conditions or slanting of the

measurement target. Errors occur in the thickness

measurement of a transparent object depending

on the refractive index. These errors can be

corrected by using the calibration function.

Prepare one or two types of known measurement

targets (masters) and perform calibration based on

the respective measured value that have not been

calibrated.

Performing calibration determines the span value

(amount of slanting) and the shift value that are to be

used to convert the pre-calibrated measured value to

the calibrated one.

The calibration function of the LT-9001 Series

changes the "a" (amount of slanting) and "b" (shift

value) in the formula "Y = aX + b".

Reference

CALIB (Calibration)

The calibration procedure is explained as follows.

1

Select [CALIB] from the [OUT1] or [OUT2]

screen.

The calibration setting screen appears.

2

Select [RAW DATA] of the [1ST POINT] using

the [ENTER] button.

3

Select the value by using the [ENTER] button

and specify the value by using the [t], [s],

[

▲], and [▼] buttons.

4

Press the [ENTER] button.

The measured value of the first point is fixed.

5

Select [CAL DATA] of the [1ST POINT] by

using the [

▼] and [▲] buttons.

6

Select the value by using the [ENTER] button

and specify the value by using the [t], [s],

[

▲], and [▼] buttons.

7

Press the [ENTER] button.

The calibrated value of the first point is fixed.

8

Select [RAW DATA] of the [2ND POINT] by

using the [

▲] and [▼] buttons.

Set the measured value and the calibrated value

for the second point in the same manner.

9

Select [EXEC.] by using the [

▲] and [▼]

buttons.

10

Press the [ENTER] button.

The calibration values are fixed.