Lull 6K Service Manual User Manual

Page 81

General Maintenance

Service Manual — Models 644B, 6K, 844C, 8K, 1044C, 10K

3-13

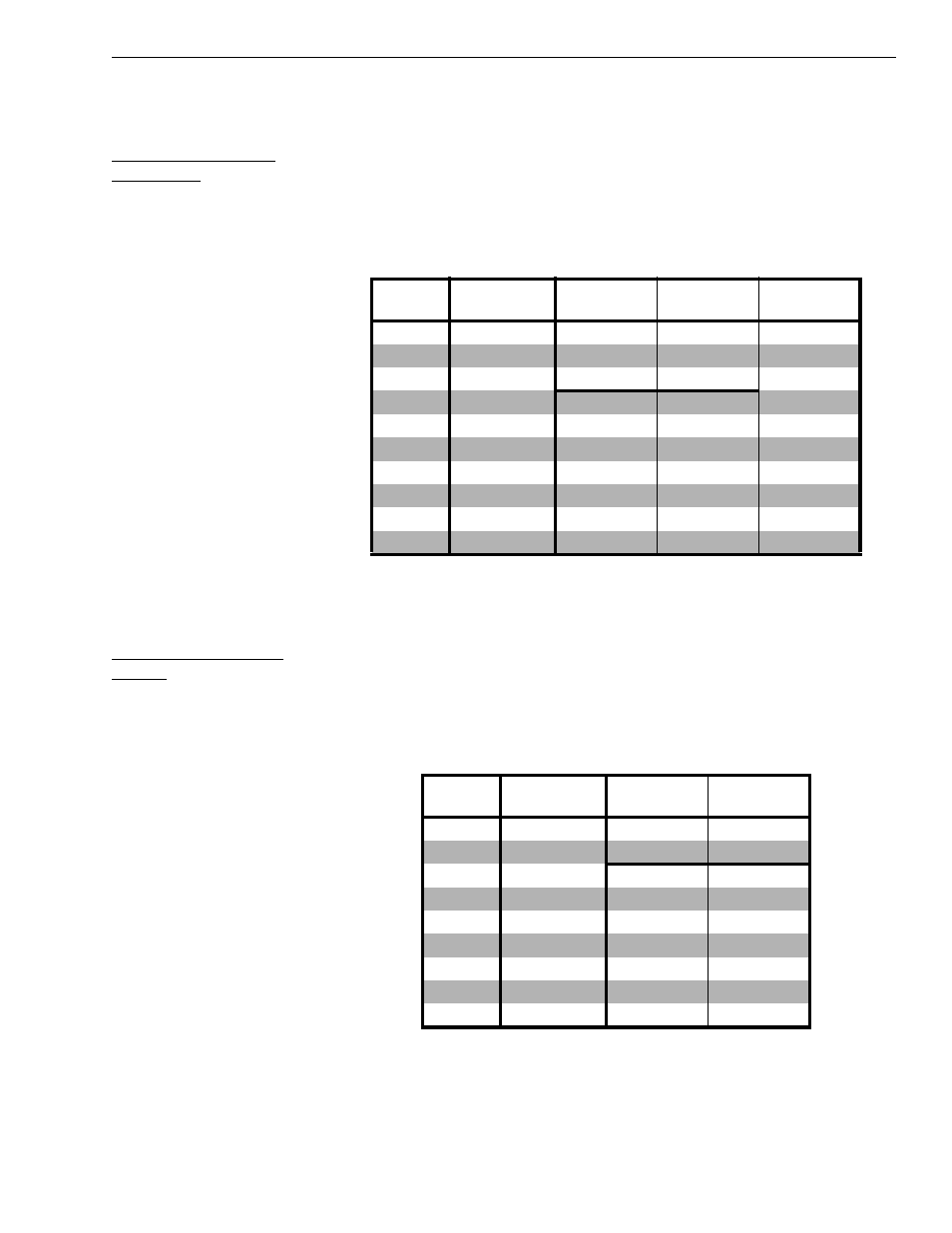

Hydraulic Fitting Torques

JIC and SAE Female

Swivel Nuts

It is recommended that the nut be torqued to the approximate minimum

value. If leakage occurs, tighten nut without exceeding maximum torque

value.

Note:

Use two wrenches to tighten hydraulic line nuts.

Table 3-7: Torque for JIC and SAE Female Swivel Nuts

Non-adjustable O-ring

Fittings

To install straight thread, non-adjustable O-ring fittings:

1. Check condition of O-ring and replace as necessary. Do not install a

fitting with a damaged O-ring.

2. Lubricate O-ring with clean hydraulic fluid and torque per Table 3-8.

Table 3-8: Torque for Non-adjustable O-ring Fittings

Size

SAE Port

Thread Size

Approx. Min.

Torque

Max. Torque

Flats

1

1. Number of flats on nut to be turned past finger tight. This

method will produce the approximate torque.

-4

7/16-20

130

in-lbs

150

in-lbs

2

-5

1/2-20

165

"

195

"

2

-6

9/16-18

235

"

265

"

1 1/4

-8

3/4-16

44

ft-lbs

48

ft-lbs

1

-10

7/8-14

50

"

58

"

1

-12

1 1/16-12

79

"

88

"

1

-16

1 5/16-12

117

"

125

"

1

-20

1 5/8-12

158

"

175

"

1

-24

1 7/8-12

188

"

213

"

1

-32

2 1/2-12

250

"

283

"

1

Size

SAE Port

Thread Size

Min. Torque Max. Torque

-2

5/16-24

85

in-lbs

95

in-lbs

-4

7/16-20

205

"

235

"

-6

9/16-18

25

ft-lbs

29

ft-lbs

-8

3/4-16

46

"

50

"

-10

7/8-14

85

"

95

"

-12

1 1/16-12

105

"

115

"

-16

1 5/16-12

154

"

166

"

-20

1 5/8-12

213

"

237

"

-24

1 7/8-12

238

"

262

"