Lull 6K Service Manual User Manual

Page 266

Boom and Transfer

6-16

Service Manual — Models 644B, 6K, 844C, 8K, 1044C, 10K

16. Inspect counterbalance valve cartridge (Item 8), including O-rings, for

condition and replace as necessary. Do not disassemble the cartridge.

Service to counterbalance valve cartridges is limited to installing new

O-rings or replacing the entire cartridge.

17. Lubricate counterbalance valve cartridge O-rings with clean hydraulic

oil.

18. Install cartridge in manifold block and torque to 30–35 ft-lbs.

19. Install O-ring plug (Item 6) in manifold block and torque to 70–80 ft-lbs.

20. Install O-ring plug (Item 7) in manifold block and torque to

125–145 in-lbs.

21. Lubricate new O-ring with hydraulic oil and install inside piston (seals

rod to piston).

22. Lubricate new O-ring, backup ring, seals, and wear rings with hydraulic

oil and install on head. Using a seal driver, install new wiper seal in

head. Lubricate wiper seal with hydraulic oil.

23. Slide head (Item 12) and piston (Item 10) onto rod (Item 13). Lubricate

threads on rod with hydraulic oil and install rod nut (Item 9). Torque rod

nut to 850 ft-lbs.

24. Lubricate new seal and wear rings with hydraulic oil and install on

piston.

25. Lubricate threads on eight (8) capscrews (Item 11) with hydraulic oil.

Coat inside of barrel (Item 5) with hydraulic oil. To avoid damaging

seals during assembly, carefully insert rod and head into barrel. Install

capscrews until snug. Do not torque capscrews (instructions follow).

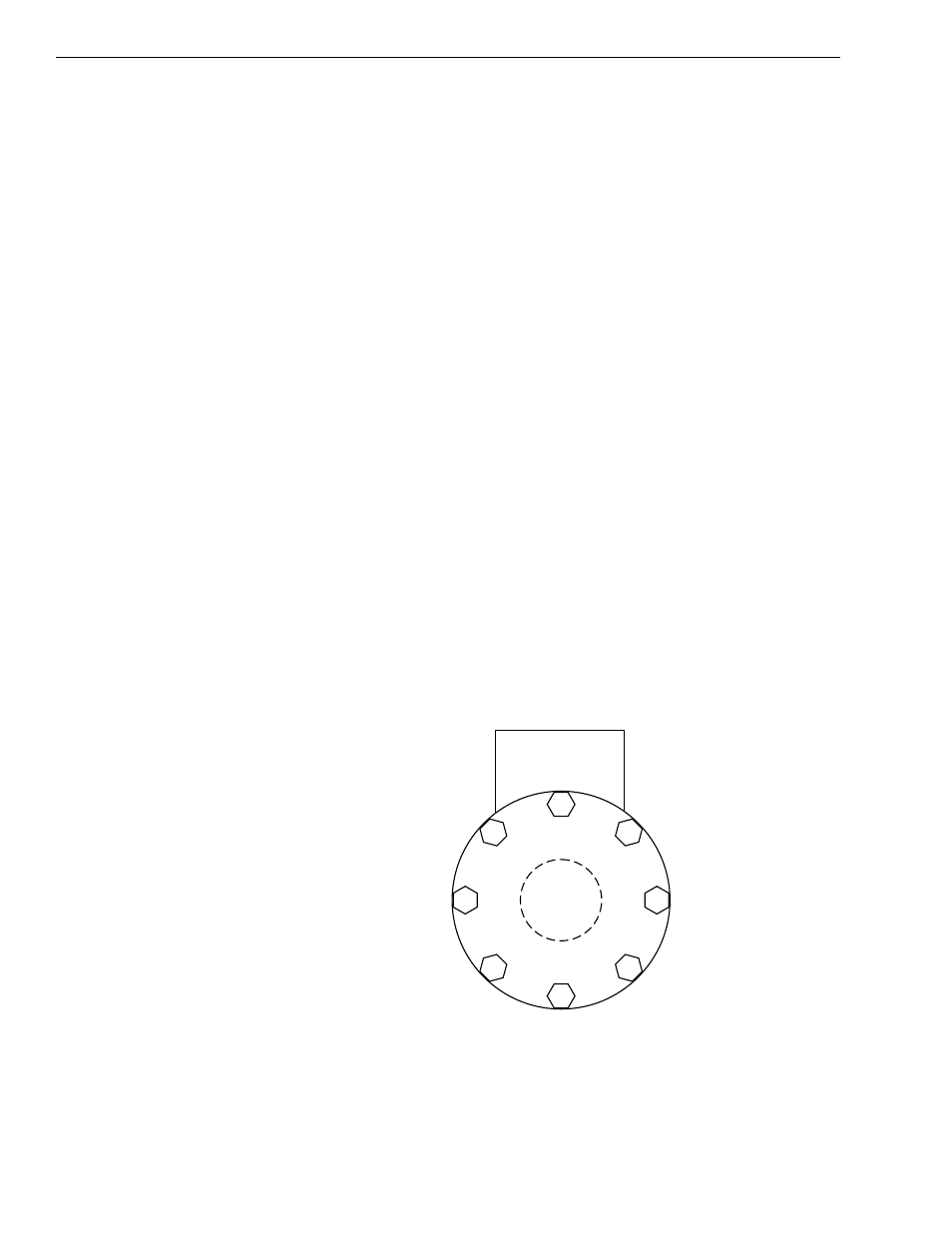

26. Following sequence shown in Fig. 6-10, torque capscrews to an initial

value of 30 ft-lbs. Follow sequence again and torque capscrews to a

final value of 90 ft-lbs.

Fig. 6-10: Head Capscrew Torque Sequence

27. Install two (2) elbows (Item 1) on cylinder manifold. Torque elbow nuts

to 58–63 ft-lbs.

28. Lubricate grease fittings with EP lithium based grease.

1

2

3

4

5

6

7

8

K1

0

2

4